Overview

Includes reference table of temperatures/pressures for smelting all metals and alloys, fuel load kPa values, general smelting tips, and describes and shows a basic gas furnace construction that can capture, filter, and feed H2/O2 in a 66/34 ratio. Once you go gas furnace you will never go back.

Smelting Reference Table

Author’s note: I’m no longer playing the game at the moment, if you notice anything wrong or out of date please leave a comment so I can keep the guide updated. I will add author contributors if requested.

WARNING: H2/O2 GAS MIXTURES ARE FLAMMABLE AND EXPLOSIVE, MIXTURES ABOVE 2MPA WILL RUPTURE PIPES IF IGNITED; FILTER O2 AND H2 AT SEPARATE TIMES. UNSEALED VOLATILE ICE IS EXTREMELY DANGEROUS. THE ONLY SAFE PLACE TO STORE VOLATILE ICE IS INSIDE MINING BELTS, INSIDE GAS CONTAINERS OR PIPING, OR INSIDE A STAND-ALONE AIRTIGHT ROOM PROTECTED FROM THE SUN.

Europa Update (WIP)

Since (before?) the Europa update the furnace has been tweaked.

Ore/Ice will get stuck in the input slot unless furnace is above a certain temperature, it seems to be 373K (100C) for most of the ores, and 273K (0C) for ice. This is also where off-gassing will occur, it won’t happen with cold ore. I now refer to this as the ‘melt’ point. The ‘smelt’ point is where you can get an ingot from the output and has not changed.

Ices can be manually melted by mashing the red button, very useful for Europa map.

If you pull the lever with a non-melted input it will pop out the output.

Other functionality seems to be the same, and the smelting table is unchanged as far as I can tell.

Please leave comments if you have noticed any other changes.

Fuel Load Pressures for 66%H2 / 34%O2

This table assumes 0C (273K) gas temp and that ore is already off-gassed at 373K; you will need to heat twice or use more fuel if you have not off-gassed your ores. If you are super-cooling your fuel gas you will need a lot less pressure. Pipe volume is irrelevant because pressure is used, but higher pipe volumes will consume more fuel.

50kPa is plenty for the lower temperature ores, and for solder, and steel, and can even smelt a stack of iron if you have already off-gassed it.

100kPa Recommended for melting lots of Iron and other Ores, this can also work for most alloys.

200kPa gives u plenty of breathing room to work all the alloys except invar, you might need to toggle the vent valve to let out some pressure depending on the alloy.

350kPa is minimum for invar, I recommend 400kPa to have more time to hit the lever. You must be ready to pull the lever between 7,000-6,000kPa. Pressure drops fast. If temperature is still too high, try a higher fuel load or slightly higher O2 concentration. Temperature will fall faster than pressure for the higher fuel loads. You can also try closing the vent valve before you load the iron ore, so the waste gasses remain in the chamber to cool the combustion.

2MPa (2000kPa) is the max fuel load before combustion exceeds 60MPa and blows out pipes. Furnace might be able to handle more than this if you wrench out the pipes before ignition.

Tips for Smelting

WARNING: VOLATILE ICE IS EXTREMELY DANGEROUS. H2/O2 GAS MIXTURES ARE FLAMMABLE AND EXPLOSIVE; THE ONLY SAFE PLACE TO STORE VOLATILE ICE IS INSIDE MINING BELTS, INSIDE GAS CONTAINERS OR PIPING, OR INSIDE A STAND-ALONE AIRTIGHT ROOM PROTECTED FROM THE SUN.

WARNING: H2O2 mixtures can self-combust inside pipes, tanks, and air volumes when heated or if they are above about 60 C 30°C (Zodiac) when mixed.

WARNING: Free-flowing H2O2 gas will self-combust if it touches ANYTHING hot in the area, like your furnace or exhaust pipe.

Minimize the free pipe volume behind the furnace to save fuel, I recommend connecting input and output with two 6-way pipes and everything else then connects through a valve or pump.

Pre-load the furnace with Ore to vent off its gasses before loading fuel. You can then load fuel gas to a specific kPa, or ice chunks, before pressing Activate to ignite and smelt the ore. To save fuel with the new melt mechanics, load the next batch of ore before venting the exhaust. This will add the melting off-gas to the exhaust gasses when you vent. Ores will not release their melting gas if the furnace is too cold (below 100C / 373K). When starting with a cold furnace, perform an initial heating to cause gas-off, or use a lot more fuel to reach smelt temperature with the off-gas product.

Mouse-over the pressure gauge to see the specific pressure and temperature inside the furnace without an atmospheric analyzer tablet.

Smelt Iron/Silicon Ore first; its smelt point is very high at 900.

Leave the lever open and keep loading Ore stacks to continuously smelt; as long as the temperature/pressure is correct the melted bars will pop out the other side.

The basic thumbrule is 2 Volatiles : 1 Oxite. However Oxite contains some additional Nitrogen gas that can be filtered out using Atmospherics Filtration Units, and will result in a perfect 66%/34% mix when capturing 2 Volatiles : 1 Oxite. The volume of nitrogen gas inside Oxite is in addition to its oxygen content.

The furnace will auto-combust a fresh fuel load if enough old gas wasn’t pumped/vented out, I recommend waiting till pressure is 1kPa before re-loading.

If you load up the furnace with an incorrect mix of Ores, it will output a junk ball. You can put this into a centrifuge to recover the Ores.

Iron Ore must be brought above 900K to make Steel between 600-900K. Iron Bars work fine as well. Steel works fine above 900K if you just want to crank it out quickly.

Regulators and Backpressure Regulators are near useless for fuel loading and gas processing, because they move gas very slowly. They do come in useful for Room atmospherics, however.

Inject fuel into the 6-way connectors after ignition to bump temperature. This is fuel wasteful if you leave it on continuously or if you have waited too long since initial ignition; it’s better to vent out and start over with a fresh fuel load.

Gas temp affects volumetric flow rates on all the machines. Your H2 and O2 feed should be at the same temperature, or you will need to tweak the percentage on the mixer for a perfect 66/34 mix.

For complete safety, use separate O2 and H2 pipe lines with a mixer valve directly feeding the 6-way furnace connection, and make sure to keep your feed gas cooled.

Tanks and canisters are generally safe to store H2O2 fuel mixture unless you leave them in a very hot room, or right next to a heat source.

Oxites and Volatiles will begin to melt if exposed to the sun or if any hot atmosphere (>0C) touches them, and then will often continue to melt completely. Store Oxites and Volatiles in mining belts, or in separate air-tight rooms in lockers. Or input them into a furnace to capture and store their gas.

Emptying your waste tank or the portable generator’s exhaust gas can be used to begin melting Oxites in an airless room. Welding Torch also makes small amounts of hot gas when turned ON. Flares generate some heat, but no atmosphere so they won’t help in a vacuum.

You can hook up power consoles to control a feed mixer and purge pump, so you can stuff a wall between the furnace and rear piping.

You can also use a canister connector (Gas Tank Storage) to fuel load with pre-charged canisters. 2MPa canister ~ 150kPa furnace load and is ideal for lower ores, you will need around 7MPa canister for invar. Just pop the canister in and pull it back out to load the furnace up, the can will be left with a small pressure. Don’t activate ignition with the fuel canister still installed, unless you want a rupture.

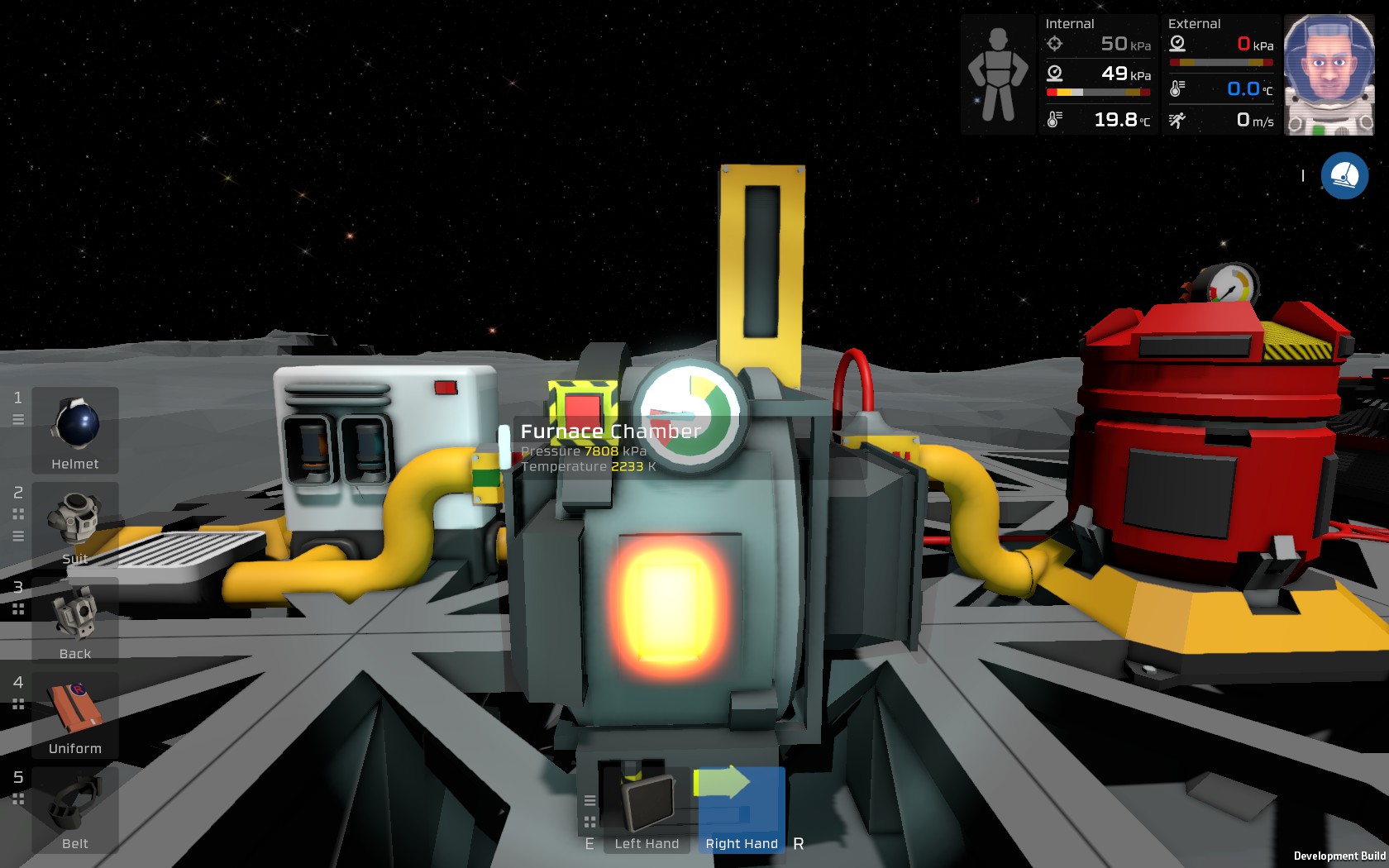

Constructing and operating a basic furnace, with pictures

The absolute minimum furnace build must be able to vent leftover gasses. You can connect a single pipe -> active vent, or pipe -> valve -> passive vent, to the output of the furnace. You can then feed the furnace with 2 pieces Volatiles (red H2 Ice) and 1 piece Oxites (blue O2 Ice). You can R -> ‘Split One’ on a stack of ice. Standing close to the furnace Input slot will automatically feed the split ice as it falls from your hands. Ice will melt in your hands if the atmosphere is above 0C (273K) or if you are in direct sunlight in a vacuum.

A more advanced furnace build can inject gas using a gas mixer or Volume Pump (1L setting) to load the furnace to a specific kPa value. You will also want a way to capture the H2 and O2 gas from Volatiles (H2) and Oxites (O2). You can use a single furnace to both capture and ignite, or use a separate furnace for capturing Ice gasses, or use a small room with an active vent.

I recommend placing two 6-way pipes behind the furnace to cross connect the input and output. Pipe “openings” are actually sealed off as long as no other piping connects to them. You can then extend your furnace’s capabilities with Valves and Volume Pumps connected to these 6-way pipes. Using only 2 free pipe volumes will minimize the volume of gas you combust with each cycle, and is the best way to save on gas. The Atmospherics structure (AC unit and Filter unit) will also function as a pump from input to output.

My furnace shown in the pictures below uses two 6-way pipes behind the furnace with 4 additional connections:

A manual valve -> passive vent (also connected to the filter waste) is used to vent leftover hot gasses after smelting to clear the chamber for the next load.

A second manual valve -> Atmospherics filter unit (with Volatiles and Oxygen filters installed) -> Gas Tank Connector is used to filter out O2 and H2 gas from Oxites and Volatiles.

A Volume Pump (1L setting) is used to feed in Fuel Gas (66%H2/34%O2) to specific kPa before pressing the red Activate button for ignition.

A Canister connector (Gas Tank Storage) can also be used to load the furnace with pre-charged fuel canisters, or your welding canister if you really need to.

The basic procedure for operation: Check that the vent valve is closed, load your initial ore, inject fuel or ice, press ignite, when pressure and temperature is correct pull the lever to release the ingots. At this point you can leave the lever open and load more ore as long as the furnace is still hot enough, or close the lever and load the next batch of ore to cause melting and off-gassing. Then open the vent valve.

If you are starting with a cold furnace will need to heat twice or to use much more fuel on the first heat; once to melt and off-gas the ore, and then again to reach smelting temperature.

Shut Vent, Load Ore, Feed Fuel, Ignite, Cycle Lever, Load Next Batch, Open Vent.

Or keep vent shut, leave lever open, load a ton of fuel, and keep loading ore until temperature is too low.

WARNING: FILTER H2/O2 ICE SEPERATELY; IF YOU MIX BOTH AND PRESS THE RED BUTTON YOU WILL CAUSE IGNITION.