Overview

(Almost) Complete guide to Furnace (with gasses)This guide is specific to Furnace as it is. Its explaning some mechanics of the Furnace. I’LL USE SOME ALLOYS/METALS AS EXAMPLE THIS IS NOT GUIDE HOW TO MAKE THEM. MY “NUMBERS” of gasses and alloys will differentiate. (theres sh*t ton of varaibles that will effect your experiace)

Before we start

All the test were done on patches 0.1.1027.5176 to 0.1.1042.5301 (18. – 19.12.2017)

This tests and guide was done on serveral patches during 3 days (more or less). I have been testing a lot of stuff and making changes to all set-ups during theses days. and im little too lazy to remake all the tests just for new patch. So resolutions may be different from your side.

One more thing before we start. I’M NOT CHEMIST. I suck at chemistry. If im not sure about some mechanics how they work ill mention it in text.

(in the backets you will see more informations or my comments). English is not my 1st language, so pls dont bash me for typos and stuff.

Why do you need Furnace

Arc Furnace cannot make everything. Alloys can be made only in Furnace.

There are few things that it can be used for (list is arranged by the propability of uses):

- Alloys (lets call them high tier ingots) – only place where that can be made (combination of 2 ores)

- Ingot (copper, iron, gold) (lets call them low tier ingots) – why you wana make it in furnace? bcs in arc furnace it takes ages (for gold) to make some.

Example : fill Furnace with 500g of gold ore and you will make ALL 500g of gold in instace. one pull. no waiting for it to melt one gram at a time.

- Gasses creation – you can make huge ammount of gasses to use them elsewhere (if camputured/redirected). Example CO2 (for plants) and even X (pollutans) (you can use X as gas for propolution to jetpack) (some more calculation how many later)

- Heat – can be used to heat up other parts of base and so. Heat is so extreme you will probably dont need that much. (but there is possibility)

Gasses and Fuels

If you undestand gasses how they work what they do, you can skip this part.

There are only a few gases that are needed to be mentioned during the guide.

- H2 – Volatiles

- O2 – Oxygen

- CO2 – Carbon Dioxide

- X – Pollutants

Gases attributes

- Pressure (press.) – how much pressure the gasses are at. Units kilo(1000)pascals = kPa (1000kPa = 1MPa)

- Temperature (temp.) – just temperature.. what do you expect. There are 2 units used in game. (little bit confusig, but whatever.) Celsius and Kelvin = C and K. For this guide ill try to stay in Kelvin.

- Mole – dont know how exactly discribe this attribute by physics and stuff. Mole = Mol. Easy to understand is that 1Mol = one unit (piece) of substance (gas).

- Liters – volume of gasses. Liter = L.(not sure how litres are calculated, but you can imagine it as how much of gasses is pumped in time. aka flow of gases in liters).

VERY IMPORTANT to keep in mind that physics works on gasses.

There are 2 laws that we will be working arround.

Presure is trying to equalize itself.Example : Tank have pressure of 9000kPa. You will connect it like this : TANK + pipe + valve (closed). And you will see that pressure (mol) is going down. You will open valve to open space (open space is at 0kPa). Your tank will empty in seconds.

Temperature is changing pressure of gasses (aka when temp rises press. rises too). ITS NOT WORKING OTHER WAY. (cannot change pressure to lower temperature)

Items used in test

(how they work, how I used them)

- Furnace – This item is really interesting. You can imagine this as combination of arc ♥♥♥♥♥♥♥♥ (has some space where you can put ore) and gas tank (has some storage of gasses and ore in one space). Has input and output for ores. Input and output (exhaust) for gasses. Gasses can flow thrue Furnace (thats why we need valves, to hold fuel inside of Furnace). It his own valve system (accesible thrue Computer taht i did not used-too lazy). It has “Activate” button. That all it does is spark iside of Furance (its not turn off/on button). Can hold more than 80MPa (was trying to test it, but the pipes blows before the furnice can) (check Bugs/Difficulties in this guide for more information)

- Portable tank – holding gasses (and water). Can hold arround 50MPa (not tested, information gathered from streams)

Portable tank holders – mounting space for Gas tanks. (you wrench from tool belt to unmount/mount tanks. when tank is mounted its OPEN so it will resurize space if its holding gasses) - Pipes – For transferring gasses to other places and STORING gasses as well. (will be important later, but rule is that dont forget to clean/empty your pipes when doing changes. explosions can happend. trust me.) Can hold arround 40MPa (not tested, information gathered from streams)

- Pressure regulators – there are two variants of regulators.

- Back pressure regulator (BPR) – one way valve. will open when pressure is higher than “X” kPa on entry.

setup example: pipe1 -> BPR -> pipe2 ; BPR set to 10 000kPa

pipe1 need to have at least 10 000kPa to open (check Bugs/Difficulties in this guide for more information) - Pressure regulator (PR) – one way valve.

setup example: pipe1 -> PR -> pipe2 ; PR set to 10 000kPa

PR will pump gasses untill pipe2 will have 10 000kPa. Will not let gasses to go back to Pipe1. (its not “open” it is pumping gases one way only in “slow” rate)

- Back pressure regulator (BPR) – one way valve. will open when pressure is higher than “X” kPa on entry.

- Valve – open/close gass flow. Manual use ONLY. (if theres pressure difference)

- Digital valve – same as valve, but can be connected to Computer/Console. (I’m using digital valve for remote access, can operate manualy or remote)

- Pipe Volume Pump – Pumping gasses at set rate of liters (L). Can be used as fuel pumps to set rate of fuel injection to system or as release “pump” (valve) to slowly release gasses. (more info later)

- Pipe Analyizer – Provide information of gasses inside of pipe. Can be connected to Computer. (This item you need to installed on pipe.)

- Passive vent – To release gasses that I dont want to use to space. (I vent all gasses. But if you are brave enought, you can store them and “re-use” them)

other (this will help you) :

Atmo analyzer cartridge + handheld tablet – With this item you can chceck Mols, Pressures, Temperature (in celsius) do you have of each gass that you are pointing at. It will shows only Portable Tanks (mounted and unmounted), Pipes, Furnace. (Its not showing content of Gas Canister)

ereader cartridge – just information needed for making alloys (pressures, temperatures and ore needed)

items that can be used, but seriosly don need at all:

Pipe Meter – shows you how much pressure you have in pipe. Cannot be conneceted to Computer. (I never used this in any of my builds)

Gas Mixer – you need this to create fuel. (i was not using this in creative mod. i was just spawning fuel.)

Fuel and burning information

How to get gasses (small tips how to make it)

mine Volatiles ore, mine Oxy ore. Its frozen. When mining it will goes right to belt. When ore is outside (hands on the floor) and theres heat or sun is shining on it, it will vaporate. so just use small chamber with glass windows. active vent to suck it to portable tank.

What i used

In this test i was using “fuel” that is ratio of H2 (volatiles) and O2 (oxygen). Ratio is 75% H2 to 25% O2. Its not necessarily to have perfect mixcute. It will just will burn a little bit less effective.

You can use ther combination. but from my test this is the most “burnable” fuel.

some small comparison of temperatures gained. (on same settings)

examples:

75/25 (fuel) 2100F peak

66/33 (made) 1500F peak

When you burn “Fuel” you will get these gasses as product of burning.

I’ll need to mention that this will be produced when you DO NOT USE ANY ore to smelt. This is just pure fuel in Furnace.

used :

H2 99mol + O2 33mol

products :

Its good to mention, that burning (explosion in my case). Is possible under certain conditions. Main condition is that you need to have certain ammount of O2 to H2 to ignite (explode).

(no other gasses)

How it all works? How you can set it up?

There are a lot of different set ups that you can do. But we can have something like T1 and T2 stuff. (some of the valves/analyizers need alloys to make them) Or as i like to call them “hand” verion and “automated” verion.

Lets start how it works. Then we go deeper how to optimaze it as good as possible.

You can have 2 variants of usage of Furnice.

- Variant A

You can have basic set up that will just pump small ammount of fuel into the furnice, ignite it and let it burn. Pump in fuel to let it burn. “Use” lever to release ingots. When done just turn off fuel. Ez nice. Not so much.Advantages: – you can make a lot of low grate ingots very fast.

– stable temperature *picture*

Disadvantage: – CAN NOT make high tier alloys (I was not able to reach high pressure this way)

– you waste a lot of fuel (gasses) - Variant B

This is little bit complicated. You can compare it to 4-stroke engine. Thats basically how it works. You pump in fuel. Close the fuel inside the Furnice (dont add any additional fuel). Ignite system. Open exhaust valve to realease pressure (at set rate). Release ingots. Let it cool down.Advantages: – can make any alloys/metals

– better for small ammount of items (or big batches of ore that you want to make)

– saves fuel (you just use set ammout of fuel, that is not wasted)

Disadvantages: – harder to set up

– needs a some testing for each set up

– takes a lot of time to prepare again (cooling down)

More of this guide will focus on Variant B (aka 4-stroke engine). Bcs its more FUN to make and you need it to have alloys.

Setup

hand made setup (aka setup when you dont have any alloys yet)

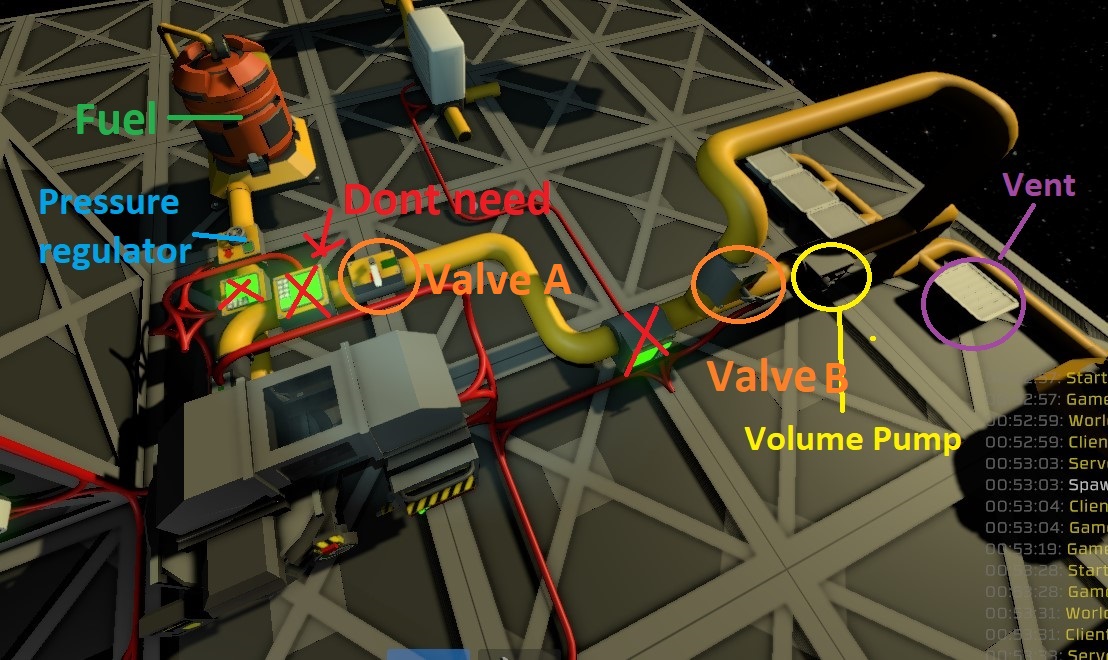

close up

Ignore the red crossed analyizers. (that was just for my test purposes)

Valne 2 is not that necessery to use. Its just for leaving it open.

Step by step what to do…

To make this piece of sh*t, ehm.. Alloy. (check ereader will give you all information about alloys)

This is what we need.

presure 6000kPa – 7000kPa

temp 1200K – 2000K

Iron 0,5

Nickel 0,5

(Iron, Nickel is 1:1 ratio)

We will use 50g Iron + 50g Nickel (one stack each)

Pressure and Temp means that. When INSIDE OF Furnace have 1200K-2000K and 6000kPa-7000kPa. You need to pull handle and it will poop out your alloy. If one or ther is not met, you get nothing. (just matterials you put in mixed together).

- Filling the Furnace with fuel

Close Valve A. Set Pressure regulator to “x” ammount. This is the time you will need some testing. You want to have arround H2 150 Mols (O2 50Mols) inside the Furnace. Use hand reader to see how much you have inside. Increase ammount of Mols if you use more Iron + Nickel later. You cannot use Computer to set specific ammount Mols at the moment(check Bugs/Difficulties in this guide for more information) (making more ammout of ore “eat” more fuel, more energy is transfered to alloy-making).

Turn off Pressure regulator.(you dont need pump more fuel for this proccess to work.)

Set Volume Pump to arround 10-15 L. Valve B is closed. - Add ore

Now add 50g Iron + 50g Nickel. They will need a little bit time to settle in side furnace. (look at window offurnace to check)

It will slightly increase Pressure and add some gasses. Ignore that. - Ignite and check

Ignite furnice!!!

Now you will need to work fast and pay attention. Your goal is to hit temperature OVER 2000K. If you did not reach have temperature over 1800 or even 1200. dont worry. Just open Valve A, Valve B. wait untill pressure and temp goes back to 0. Go back to step one and add more Pressure on regulator to add more fuel. More temperature = more time to act.

So now you hit temp over 2000K. Your Pressure should be arround 10000kPa-12000kPa (10-12MPa). Its normal. Just open valve A. And just watch pressure INSIDE THE FURNACE.

Temperature is lowering at slower rate then Pressure. Lowering pressue is regulated by Volume Pump. IF your temp after while is under 1200K (target) and pressure is still over 7000kPa. Set Volume pump higer (increments of 5L, recomendet). “Clear” system (Open Valve B, wait for temp and Pressire go to 0), back to step 1.

If temp is over 2000K (almost never happend to me) and pressure is under 6000kPa. Lower Pump valve (decrements of 5L). “Clear” system (Open Valve B, wait for temp and Pressire go to 0), back to step 1.

If temp is in range (1200K-2000K) but pressure is under 6000kPa. You just released too much pressure (it is released too fast to react). no problem. Lower Pump valve (decrements of 5L). “Clear” system (Open Valve B, wait for temp and Pressire go to 0), back to step 1. - Hitting the sweet spot

You are almost there. Pressure and temperature is in range. Look at the window and you will see something like this

Pull the handle. Poops out Invar ingots.

Congratulations !!! Your 1st Invar (other alloys too).

Invar is one of the hardest to hit the sweet spot. Because of the pressure range (only 1000kPa).

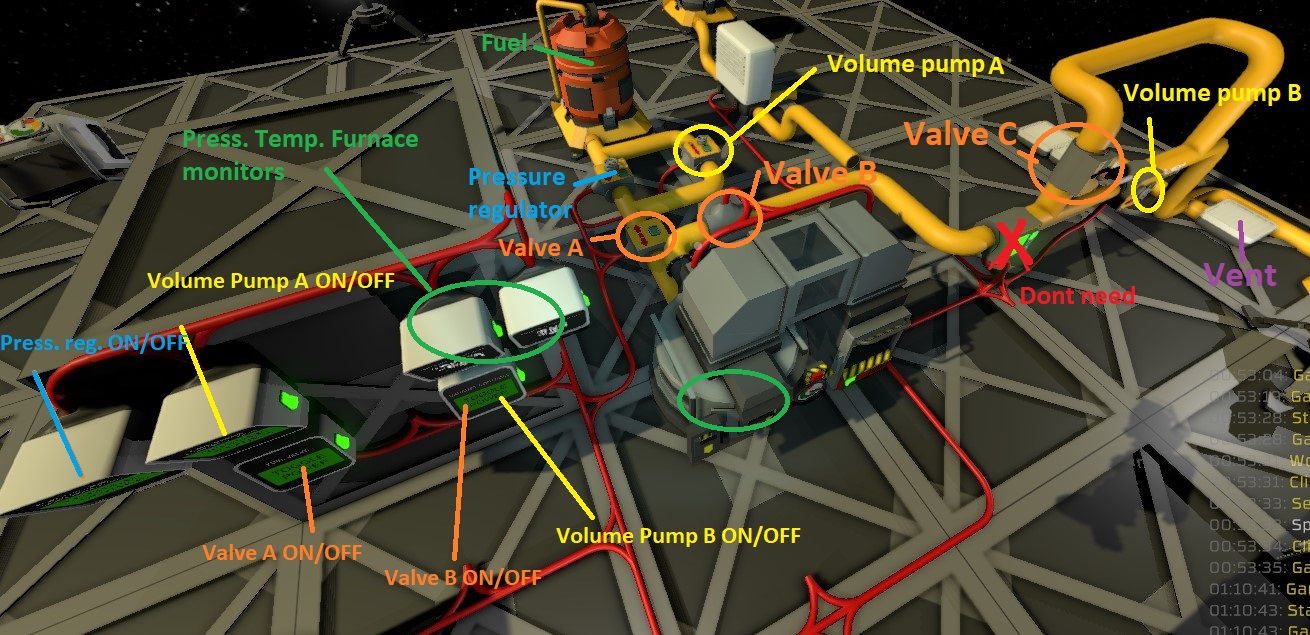

“Automated/advanced” setup

Some of the components will need alloys that you will be able to make from “hand made”setup. Its just upgraded “hand made” setup.

Pricible is still the same.

Same thing more efficient.

(could make more precise, but there are some dificulties related to that. my laziness.)

if you want to try it yourself. You can download map from workshop DONWLOAD MAP WORKSHOP

Optimalizating your setup

(will use my “advanced/automated” setup)

- Volume pump A open for “x” L(your set up will be different). This set up is for constant burn when using Pump A. (only used for making low grade ingots)

- Pressure regulator to set up ammount of Mols inside of Furnice.

- Valve A and Valve B are set up as close as possible to save fuel. Before ignition. Just to hold fuel in one space. (Furnace dont have fuel aprt and exhaust part. All is going thrue same pipes. So you are pumping some of the fuel from exhaust. thats why you want to close it as close as possible)

- Distance from Valve A to Furnice is also important. (IF fuel is burned. And you have still left over fuel in pipes. so than it will eventially goes into furnace and explode. and than its harder to controll Press. and Temp.)

- Valve C is there just for fully opening exhaust, to “clear” system faster.

- All the console on left are just for easy access. (only Pump B and Valve B are set open/close at the same time.)

Other stuff

(not needed to read, but helps when you want to make changes to the system)

Holding temp high (above 1200K) and fueling all the time (letting it burn all time)

– pressure is rising faster then temp when constant burning. Fuel will not burn, just because you pump it inside. It needs to have some ratio of H2 and O2 to burn. If you are pumping fuel at high rate to feed it up. You are just pumping fuel thrue exhaust. without burning it. (CO2 is likely to fill up Furnace and therefore there is not much “space” for H2 + O2)

– with some fiddling you should be able to set it up. But the tick rate (when game updates informatio for press/temp) is too slow. And jumps in temp are too high.

Back pressure regulator – (you were probably screaming to use back presure regulator instead of volume pump on end) will probably be the easiest thing to hit set pressure. Just set it to 6900kPa and release the rest. The issue is BPR is not releasing pressure (gasses) as fast as volume pump. I did not tested set up 5-6 BPR next to each other. could work. not sure.

Computer controlled release of gasses (adding fuel) – The tick rate how fast is the game checking reads from Furnace/analyizer. The pressure jump is too high that i was missing temp/press goals. Pumps/valves did not close at set value.(maybe with some fidleling you could be able to hit sweet spot)

Computer controlled Fuel to Furnace – wanted to set up system that fueling part will stop at set ammount of Mols inside of Furnace. There is option to read rate of gasses in Furnace, but its bugged.

Only Computer controlled system (fueling, adding ore, ignition, exhast, opening furnace, clearing) – too lazy/dumb to set it up

Bugs/Difficulties

(not sure it is suposed to work like that)

– Back pressure valve is not outputing volume of gasses at high rate.

– Tick rate on how fast is the system updating pressure and temp information.

On high pressure the pipe analyizer (pressure messure in furnace as well) is not updating fast enought so when you open valve fully it can release more presure that you wanted.

example : your set up looks like this

Furnace Output -> Digital valve -> open space (all information connected to Computer)

Furnace presure is 11 000 kpa. Computer regulated system is set up to close at 7 000 kpa. You open digital valve (aka 0kpa atmosphere). System is updating at some rate (dont know exact rate). So Computer will receive information of pressure at (example) 9500 kpa than next “update” is 8500 kpa, next is at 6500 kpa. Than Computer will send information to valve to close it. What is 500kpa late.

– Consoles and/or Circuitboard Gas – I was using consoles to show temperature inside of Furnace. It showing only in Celsius and you cannot switch it for Kelvin. (without logic system)

– Atmo analyzer cartridge + handheld tablet – showing temperature only in Celsius (C), cannot swtich to Kelvin (K).

– Furnace and Computer read – Furnace for some reason is not outputing Mol information about gasses to computer. (pipe analyizer works. your comment:” so why you dont use pipie analyzer for that same thing.” my answer:”becase you use one more pipe to fill with gasses aka wasted space and accuracy of mesurement and im lazy to add numbers”)

End word

If you finished this guide… congrats. one heck of a long guiide.

All this (guide and test) took me aproximatly 7-8 hours to make. I hope you will find something interesting from it.

Hands down for the developers. As i can see how fast they are pumpung patches is incredible. Bugs and new content. Keep up good work. Love the game. ^^