Overview

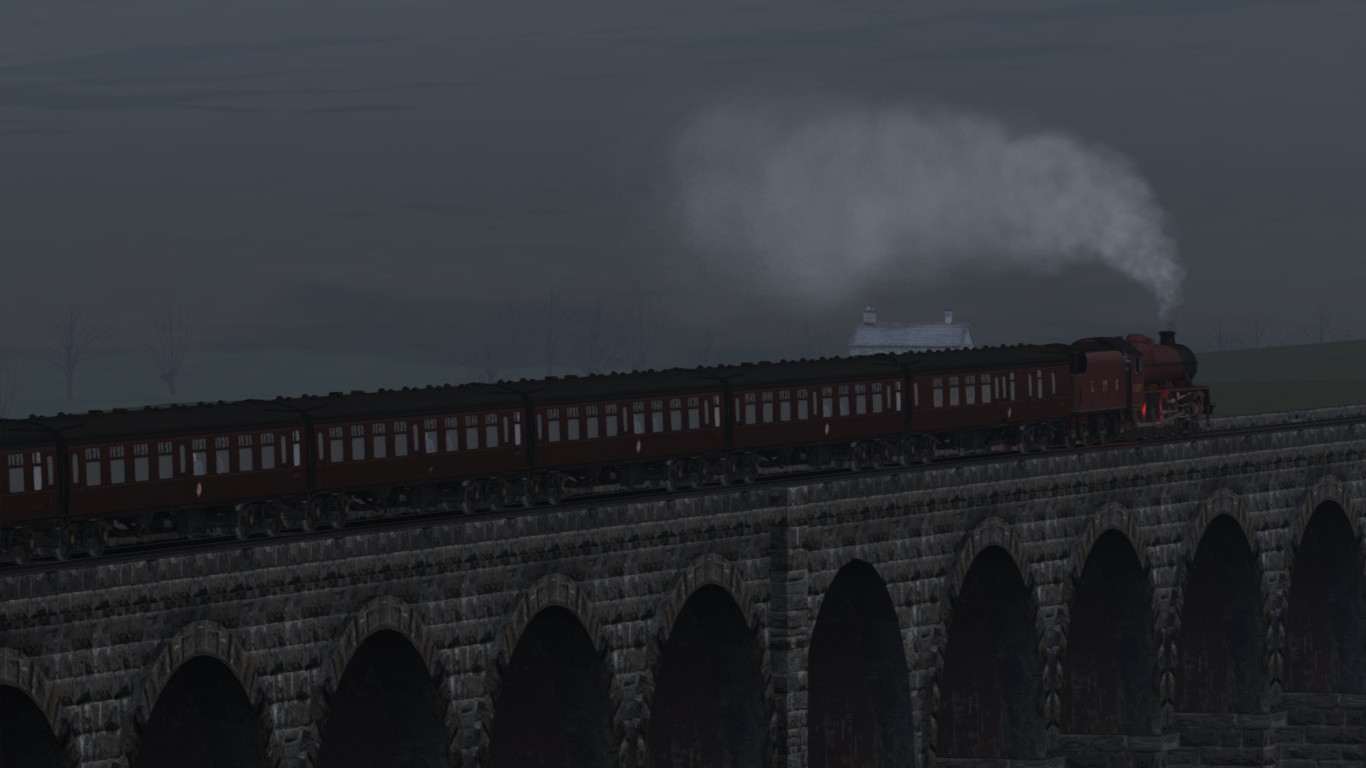

> Expect loading time due to the amount of images and videos !!Start update: Nov 19, 2015. 11.00 pm / 23.00 hrs Scroll down until you find your desired subject then click the chapter you want to studyChapter group content overview: Introductions All the basics needed for driving with steam locomotives All the signalling aspects that inhabits TS2015 All the extended driving skills Specified engines that needs special attention on driving Engine maintenance Practical issues Additional artistic issues Finally AppendixesNews about this guideThe coming of TS2016 brought some amazing lines and engines. The Riviëra Line for example with the King, Castle, Grange and the Pannier will be added to the chapters together with the German class 86. Beside that the Just Trains 5MT will be part of the new added chapters here in this guide.Other new chapers that are in prepararion:The BR-LNER J50The 2F Dock TankThe LMS 3F JintyThe GWR 4400 Small PrairiesThe ConsolidationOther new chapers will be:Driving with PZB / IndusiDriving with the vR E03, E10 and E40 Expert line during the steam eraGerman rolling Stock in the 60’s and 70’s The guide “Driving the steam locomotive and the technical aspects is now one of the greatest free educational resources ever brought online worldwide that combines practice skills live steaming and virtual driving together in one single guide. The guide contains 70 chapters and is based on the famous book “Leitfaden for der damfplokomotive” from “Niederstrasser”. and the German “Eisenbahn Lehrbucherei” The guide is enhanced with video’s, British footage resources and more.To create a better access in this guide the chapters will be grouped together. Each group contains the specific information according the group target.[/i]When a mistype had occurred please notify the mistype at [email protected] rephrasing the chapter and paragraph where the mistype has occurred. Then the correction will be made as well. If there is any supplementary or commentary please notify the writer and owner using [email protected] with an * is set for maintenance and major correction.Chapters with an ** endures maintenance and correction.Chapters with an *** are new chapters, which are in preparation and construction.Have a nice and educational study.

1.00 – Introduction

All issues about the introduction are mentioned in the chapters below.

1.01 – Preface

Based on experience and knowledge Mr. R.C. de Visser. Author from this guide and owner of Steamtrains Unlimited will now lift the secrets of driving and maintaining steam locomotives in all aspects of their preserved existence.

The guide as shown here contains actually 3 guides. The guides “Additional information of steam locomotives” and “The signal guide” were meant to be a stand alone guide in the workshop.

However the need to merge these guides into 1 guide was necessary keeping all information in this one single guide is rather required to drive within TS2015, MSTS and Trainz or other train simulators.

To aim the educational purposes and efforts in your hobby as an enhanced source of detailed technical knowledge and how to practice this knowledge as far as possible within and without TS2014 and other trainsimulators such as the old MSTS.

The information is even useful to practice in reality at a club or society on every working steam locomotive available. Wherever it is a steam powered N-Scale model locomotive, scale 1 engine, Minature Railway 7 1/4 inch or the original. with some interpretation you can do it all with this guide.[/h1][/b]

Steamtrains Unlimited exists since the coming of MSTS and was online as MSTS-Steamtrains. Some later the name changed into Steamtrains Unlimited aiming to promote the steam locomotive all over the world. To boost the hobbyist to become a member from a certain club or society preserving steam locomotives and even preserved a historic rail line and to keep the engines certified in running conditions for steam specials and additional purposes concerning rail travel.

This preface is now taken over some of the text which was meant to be in the brief introduction, but the amount of text was increasing and requires a separation of text into a new chapter. The index which is on the left is now better visible. In order to get the best out of this guide which now becomes more like an online e-book at this moment. More changes are going to take place in the near future to have the best advantage form this educational guide and e-book.

The upgrade was started in October and is now in a process of refining and correcting now.

Some educational issues and explanations have to be added still, but until so far, you already have a major study to devour.

Any mistyping or grammar violation will be solved during the refining period. Either the additional new chapters are at this moment in continuous review to eliminate errors as much as possible. However if you noticed a mistype or any text error, please notify the error at:

Steam in all its purity is the best natural power source there is, no other power source is stronger than steam.

Though the guide is since the upgrade finished, it is not fully complete at this moment. This means additional information is still brought in this guide. At this moment the guide contains over 65 chapters and is still expanding.

1.02 – The introduction of driving steam

Oktober 2014, After the coming of TS2015 and some major engines that has been brought out, an update of this guide was needed. Now educational video’s are added and some chapters needs to have some reviews as well in order to keep your performance updatet. Some articles has been added to have a better understanding of ongoing apects concerning the technics.

Is it handy to have TS2015 as a good basical educational study software prior to that proffesion?

Yes is it handy to have. It will introduce you into the world of modern train driving.

It will also introduce you into the world of the post steam era as well.

Some routes are usefull to get the understanding route knowledge and the basical things, but in practice the effort of TS will pay off and contribute to the job at the railroad compagny.

Take all the time to read this guide over and over again take your advantage on this knowledgements and yes this information is free. Get familiar with all equipment and drive your way around on steam trains.

Steam however is playing with thoughts and minds, even those who are not interested in trains at all will stay and watch a steam train passing by on steam specials. It is the way a steam train acts, reacts and works. It is a feeling of steam that keeps up mankind for continuing their motions and acts.

This brief manual will explain some major important issues you have to take care of before you even start to drive. All though this is a simulation you do not want to have a fatal blow back or a priming boiler. This will end your game as well and you can all start over again.

Lets hit the shovel and start to stoke and fire up this amazing wonder of technique. In order to drive a steam locomotive it is necessary to know the basics mathematics and techical aspects of steampower.

The guide is also usefull for MSTS. though check out the keyboard chart when you have not

reassign the key assigments in the MSTS game options. When you still use MSTS, you better reassign your keyboard. The left side of an USA standard keyboard (QWERTY) is suited for stoking purposes. The right side the nummeric keyboard is assigned for driving purposes.

The keyboard assignment option is a feature that is lacking in all releases from RS2012 until TS2015

Many drivers are switching to Automated Fireman because of the lack of knowledge, understanding and experiance of driving this amazing type of traction.

This is unadvisable except you are new to TS2015.

Newbie’s better start to drive in simple mode. Using simple mode will take care of all things newbie’s are unfaliliar with.

When you are new to TS2015, you better start in simple mode. Explore routes with a diesel or electric locomotive before you set of with steam anyway. Practicing steam driving needs a lot of skills, even is this simulator. This guide teach you how to drive and find the right balance between driving and stoking.

Take your position at the footplate of the engine and be prepared for your run. In this manual with pictures during a run or from real engines. All basics of driving a steam locomotive is mentioned. When you have tried it all properly and study all the material taking notice of all efforts you will have a major driving experiance. All mentioned issues are taken from Real-Time experiances and examples.

When you are member of a club or society concerning the restoration of steam locomotives, you then have a good and proper basic to move on. And of corse this is simulation, but the increasement of your knowledge will also increase the fun of this simulating enviroment.

First of all

In order to get the full advantage of manual driving you have to disable some features in the game option of TS2015

- Open TS2015 and go to the option screen

- Disable the automatic fireman by unticking the checkbox and clear the game cache.

- Restart TS2015, Choose your engine in a free roam environment or standard environment.

- Read carefully the next chapters and start practice all the mentioned methods and issues.

- Try to pick up the lessons in theis guide while running a steam train.

If you want to learn to drive, you better start with a diesel or electric in the Academy mode to get the best and proper understanding of driving a train. The Academy shows all basical aspects about diesel and electric engines and even the use of advanced driving methods and signalling issues.

The lessons thought concerning driving a steam locomotive by the academy are very basical and does not provide all the information, nor in simple mode, neither in advanced mode. You better do not rely on the Academy. There are quite some issues mentioned that does’t fit the real way of driving the steam locomotive.

You goal is to drive like an expert. This will improve your knowledge and skills and you are actually ready to become a real engine-driver after all.

then move on to Chapter 12 and read what is needed to get on that train, but……

Failed? Don’t worry just start over again.

R.C. de Visser – Steamtrains unlimited

Facebook: www.facebook.com/steamtrainsunlimited

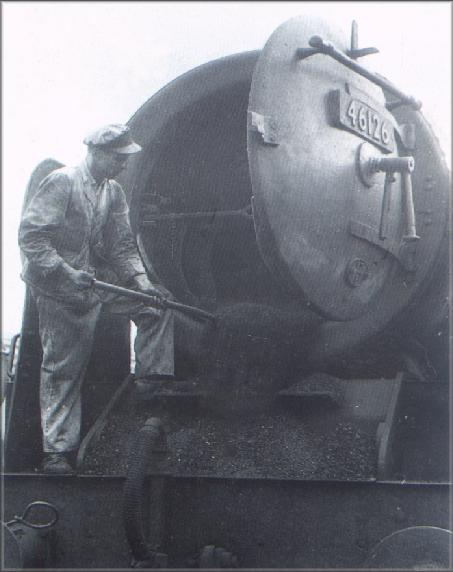

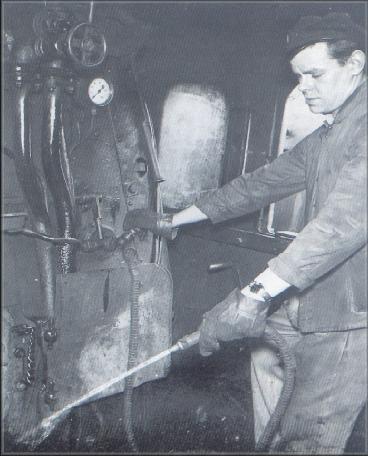

Mr. R.C. de Visser during a firemans shift on a open day at the depot in 2004

Copyrights:

All rights reserved by Steamtrains Unlimited – R.C. de Visser

The use of pictures, images, photo’s, graphics, drawings, diagrams, screenshots and video footages are permitted by restrictive conditions only: to present and show for educational purposes concerning this guide.

1.03 – Preparations to start

This Guide will reveal to you how to drive a steam locomotive as it should be. Let’s start to prepare ourselves before we pop off on any route with a steam locomotive. Check all wires and cables. the monitor(s) and PC(‘s). Make yourself comfortable.

When everything is set and you are well prepared now, then the time will come to drive. You have to get common with all the functions and knowledge, either with the route you drive you have to get familiar with.

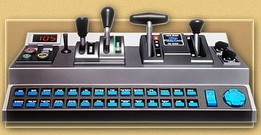

The shown configuration is even useful for TS2015 as well. Just change the flight yoke for a joystick and remap the functions to all controls needed and fitted for driving steam locomotives.

The use of an 2nd PC will either enhance the feeling of driving, it will provide additional information like track lay-outs, Time tables, track warrants, Track information sheets, train calculations, signal aspects and more. A good joystick mapper is available at digital transforms, for some money you have a great well working mapping utility which is only needed when the joystick supplier does not provide a mapping utility.

Equip your PC with levers, (rudder)pedals and joystick, map the axles of the levers, joystick and pedals to the desired keyboard combination. The pedals, throttle quadrant and joystick are often in use for Filght simulators, but mapping the keystrokes to the joystick will enhance and expand the feeling and freedom of real driving.

1.04 – Using a Joystick

TS2015 can be run with a Joystick as already noticed in chapter 3.1, Throttle and (rudder)pedals. It seems quite weird, but with some 3rd party software add-on’s you can easily activate a joystick, rudder pedals and throttle to your TS2015.

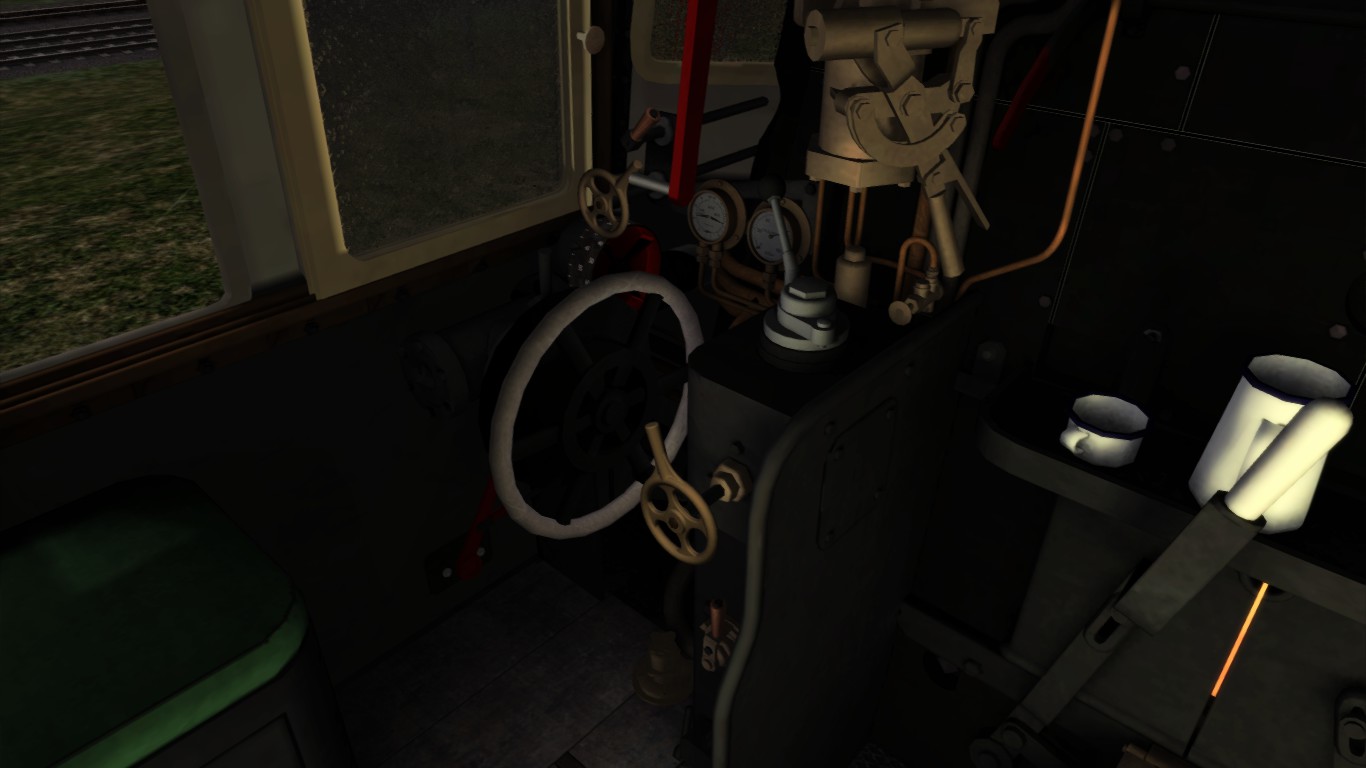

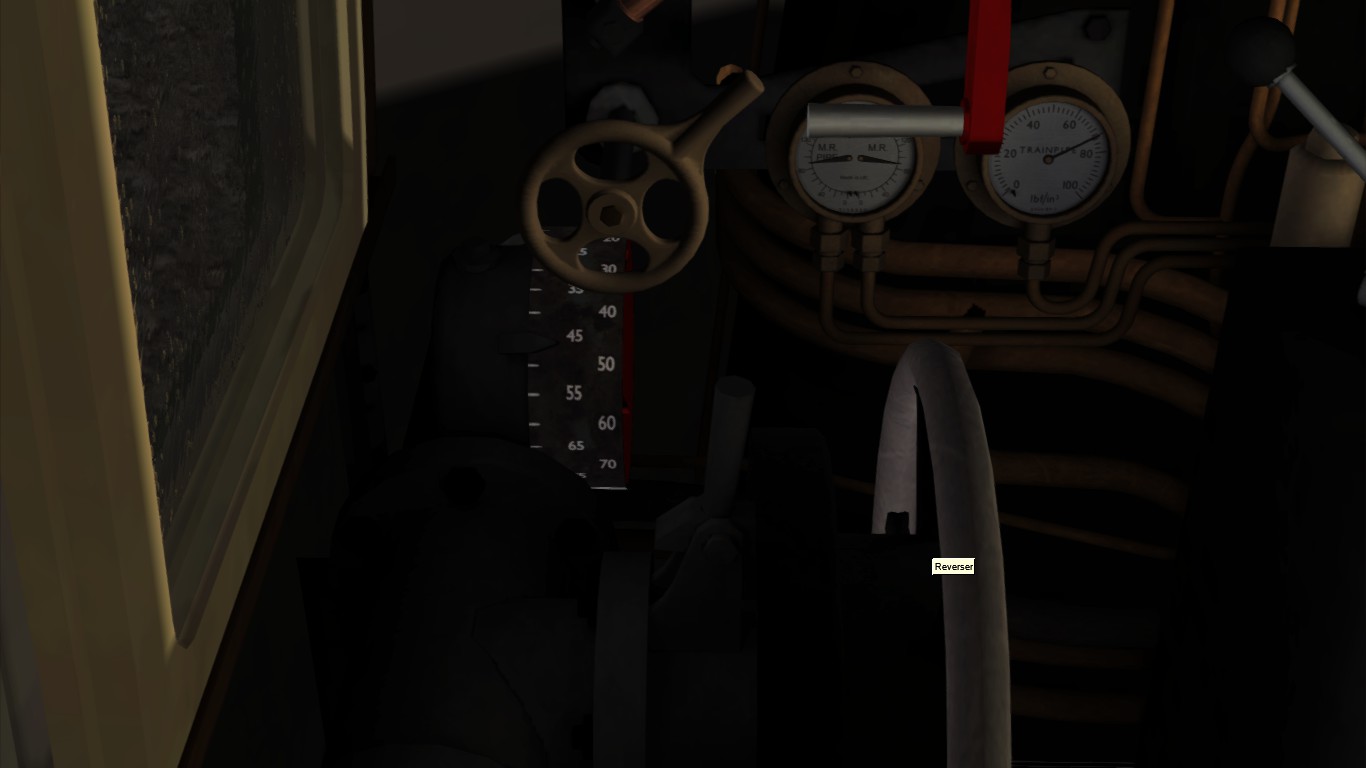

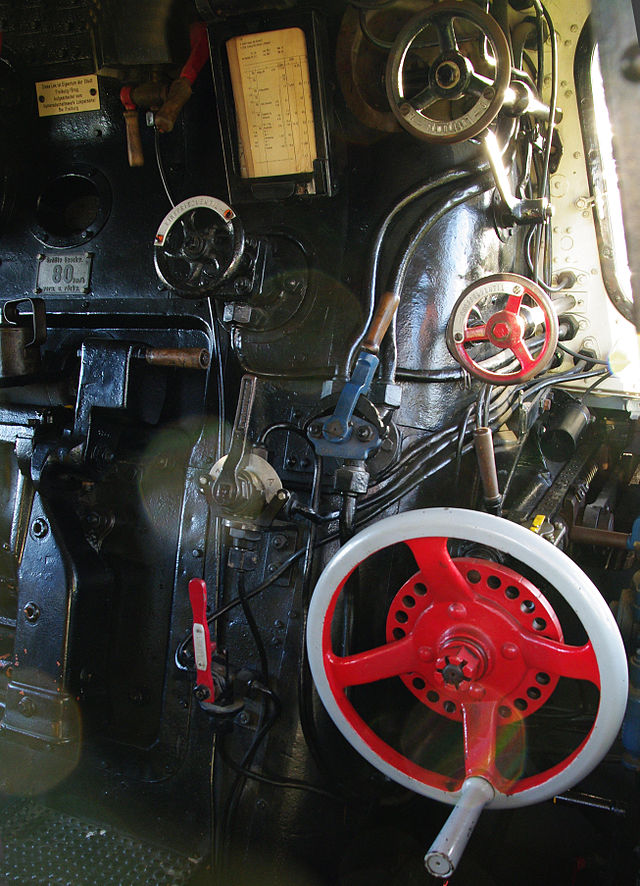

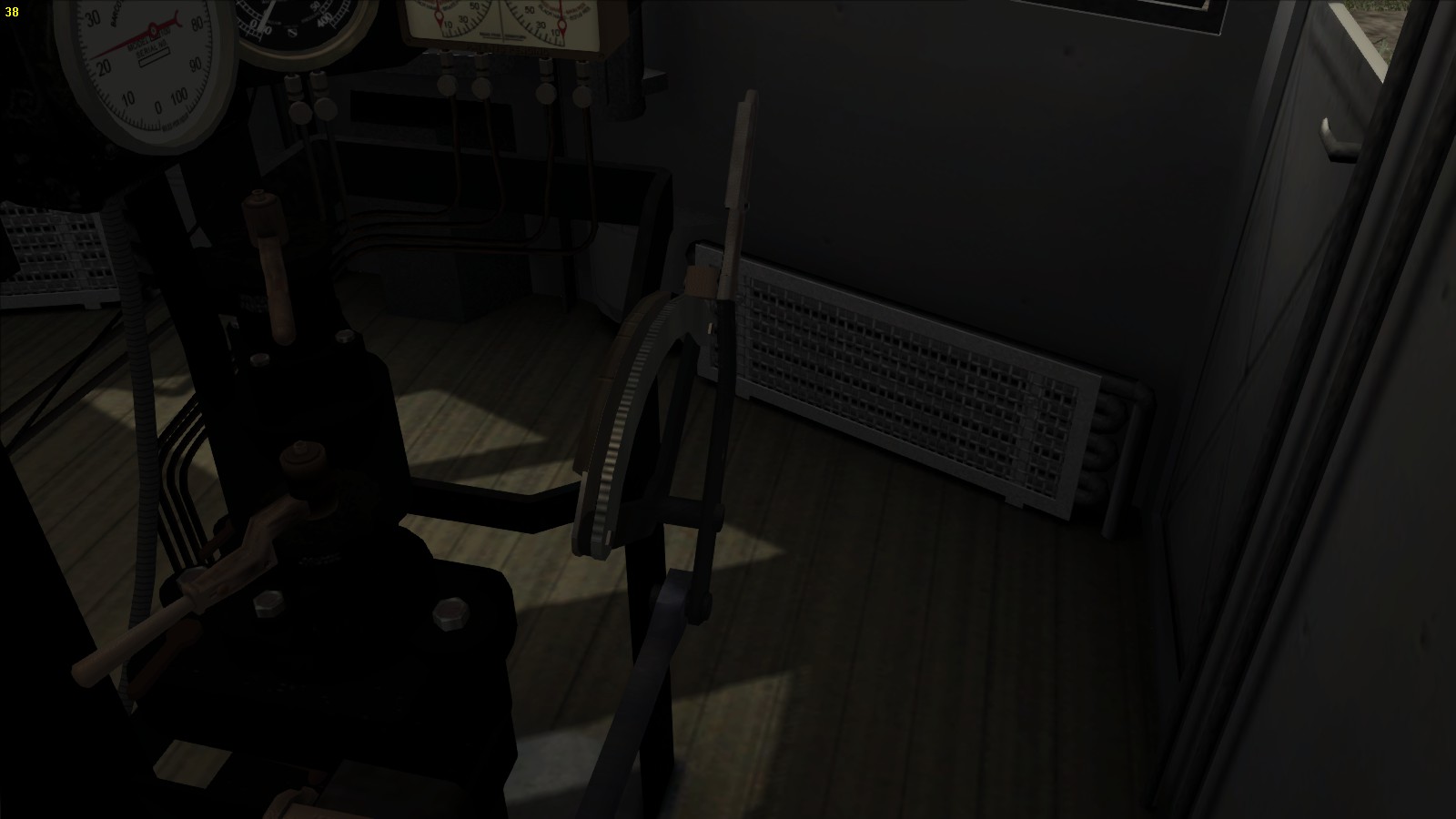

Try to make any connection with the footplate, levers, gauges, handlebars, reverser, regulator and indicators of a steam locomotive below.

The Raildriver console suits diesel and electric locomotives, but the Raildriver console does not catch up with the footplate of a steam locomotive at all. The connection to a joystick is even better then the commonly known Rail Driver Console. However the Raildriver Console is an good solution for the use with any TS. Raildriver still lacks the steam locomotives features. Though Raildriver is programmable, the console itself is an off-spring from the Dash 8 console as you could compare both consoles.

Some model railroad manufacturers has developed some amazing cab controllers suited for use with model trains. These controllers are quite expensive but it is well worth to have a short look on these cab controllers / consoles.

These controllers can be used for model railroading but these cabs should fit different DMU’s and EMU’s. Uhlenbrock created the hand wheel driven console which is quite suitable for diesel and electric loco’s like the locomotives made in the 50’s and 60’s

The joystick seems a simple device and either not comparable with a steam locomotive.

The truth is still different. The joystick can be programmed to fit the main controls. in extension an additional throttle and even pedals can be added to gain a full simulation experience.

On top of these extensions, a further enhancement of levers can be added. Saitek has a simple three lever console with three buttons that can be expanded with more lever sets combined with each other. On your imagination you van install a rack with 5, 6, 7 and even more sets together and assign every lever seperately from each other. Together with the joystick, throttle and (rudder) pedals you can achieve a tremendous feeling on driving a steam locomotive.

Passionated virtual pilots goes even beyond everybody’s imagination and install a cockpit in ther own house. Every device visible at the console, throttle quadrant, overhead panel, side panels is functional.

The levers are aimed for flightsimulation. Two, three or more lever consoles will boost the simulation experience. Each lever can be programmed separately using the programmable software as it comes with the levers. For Saitek the program is called SST Every lever block can be assigned to different operations. Together with a flight yoke of joystick set, you can now configure the controls according the engine you like to drive. If you are not able to get the Saitek levers or the SST program visit Digital Transforms and download Total Game Control. This tiny program allows you to map the joystick to operate the keystrokes. Total game Control is game independent, so it can be used for all Trainsims you have installed. Just create for every trainsim and either add-on engine a separate profile and.

Do not mix up keystrokes such as MSTS keystrokes with TS2015 otherwise you will have problems because Total Game control does not check the game in relation with the keystroke mapping. If you should use the D instead of A to open the regulator, you close the regulator instead of opening it. Though many key assignments are rather the same as in MSTS.

Based on a German engine with standard regulator and axles only. Buttons can be programmed as desired.

Configure the joystick at the LEFT side and the throttle at the RIGHT side, because the German regulator is left from the driver. The brakes are positioned at the right side next to the window. For left hand operated engines like British engines, just reconfigure the joystick, just mirror the positions to the other side except the forward and backward motions / operations.

The Keystroke mapping as follow:

2.00 – The basic of driving with steam

All issues from the cold start to the very end of the shift will be issued. It takes time to study all the efforts as notified in this basic guide.

All the instruments, equipment for as far as possible within the core limits of TS2015 are notified in the chapters below:

2.01 – How a steam locomotive works

Before you really start to study and practice the guide, take notice of this chapter first. It is going to tell you a brief overview of the working and technique of the steam locomotive. If you are ready with this chapter, you know some history the very basics of the steam locomotive.

One of the greatest inventions and discoveries in the world of today is the steam engine. A steam powered source was translated into a motional force able to do heave jobs. Famous names like

R. Stepheson, W. Murdock, E. Vivian, E. Murray, R. Trevitick and more. They all has contribute their inventions and developed a standard transport mass system in hauling freight that is spread world wide. It has an own infrastructure and it is capable to transport masses of freight and passengers.

You have probably watch the documentary about the history of the steam locomotive, the impact this invention had in the modern world. The industrial and economical boost what took place after this great invention. Especially the steam engine in particular has brought a tremendous effort and made the horse powered wagons to haul coal cost effective. And now you are a part of this invention. Trying to make yourself comfortable with a steam locomotive, hoping to understand the working of an engine and the equipment. However this chapter reveals only the brief history and the brief explanation of the very basic principles of the steam locomotive.

It is simple to create steam, the use of steam ws already discovered by the Romans.

They put water into a sphere with nozzles aimed in one direction. When the water was heated up by a heat source the water started to boil producing steam. That steam was blown out of the nozzles and the sphere started to turn around. The Roman emperors were afraid that this would result in the industrialisation of production. The emperors should have to release the slaves, and lost their investments in the “deals” with slave traders.

However the steam engine was born. but the development was stored away for a long time and after the end of the middle ages, at the start of the 19th century, industrialisation kicks in and the need for speeding up production lines was required. Increasing the production lines means more rough materials, liquids, pre-prepared products were needed, but the transport system was not suited to transport large quantities so a solution was desperately needed. R. Trevitick developed an engine that was able to haul a certain amount of wagons along a rail that could carry freight, more freight than by vessel or a horse powered lorry. That engine was the steam locomotive the Trevitick Coalbrookdale locomotive and was the first step in railway developing.

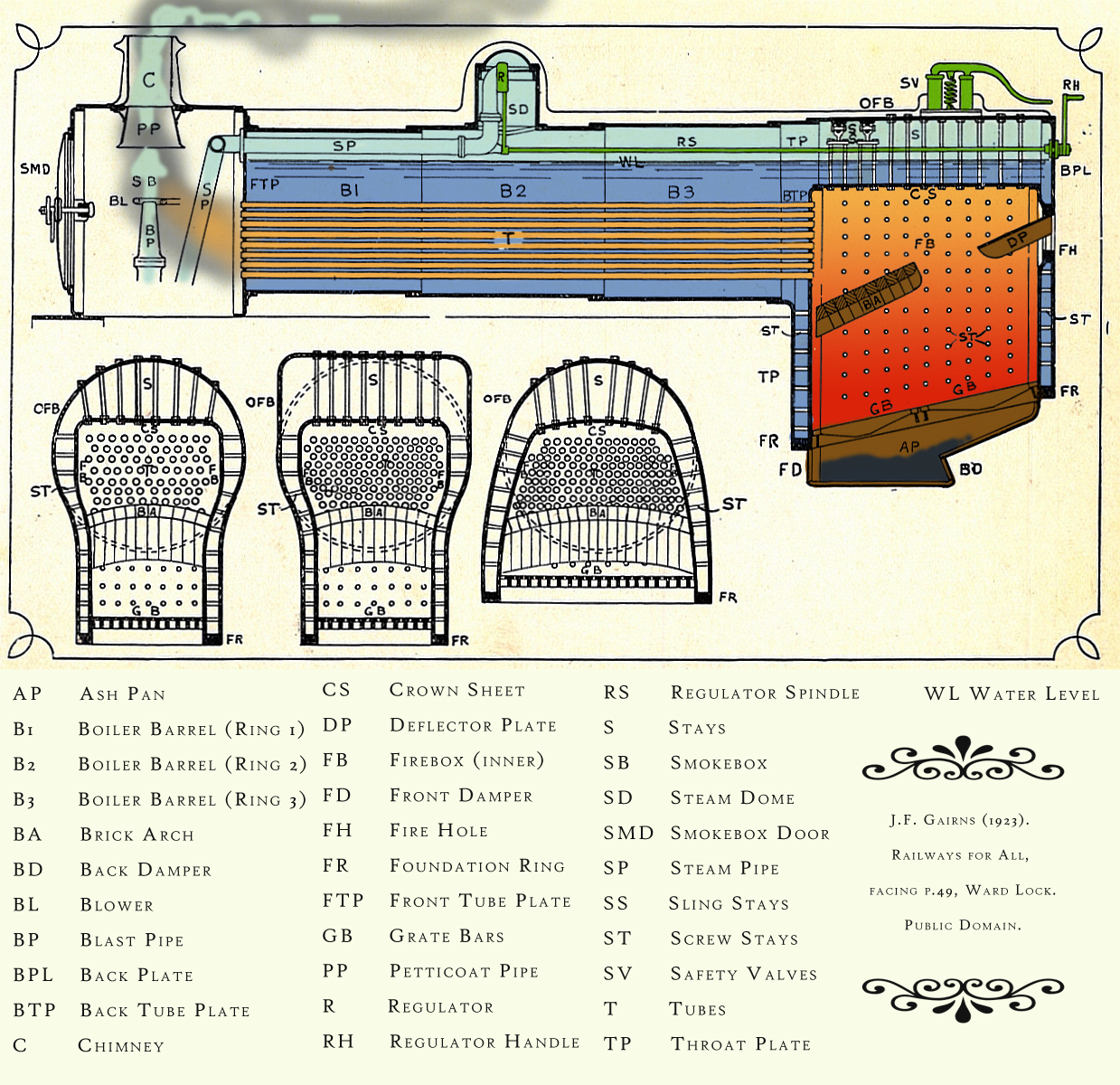

Based on the Roman concept, the steam locomotive works pretty much the same.

The sphere became a boiler that was heated up causing the water to boil and evaporated into steam. Steam is a gas that could be compressed. Compressed steam becomes pressurized and was powerful enough to blow something away. This force is now ready to use as power supply.

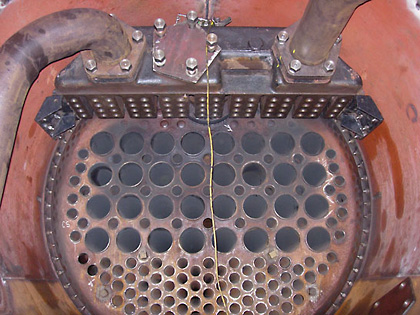

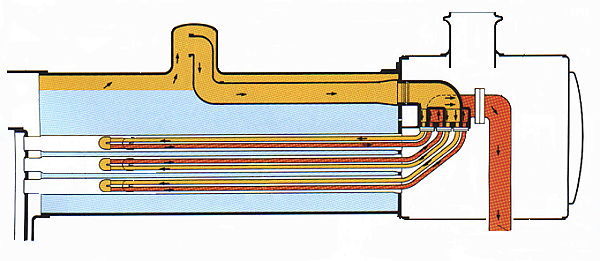

The boiler was developed and in the development the engineers discovered that a horizontal boiler could contain much more steam power instead of a vertical boiler. in the boiler many tubes and pipes were installed for the most economical method of heat exchange to the water.

The boiler now could stand more pressure and was quite easy to install on a frame that was supplied with wheels or even static in a power house.

Steam was produced and transported through a pipe to a engine that translate steam force using a cylinder that contains a cylinder head mounted to a piston. The steam pressure “blows’ the cylinder head with piston into one direction. On top of that cylinder a steam divider was installed. to divides the steam on exact the right moment to the other side of the cylinder head resulting the cylinder head with piston to be “blown” back. Again the diver changes direction and the whole sequence starts all over again.

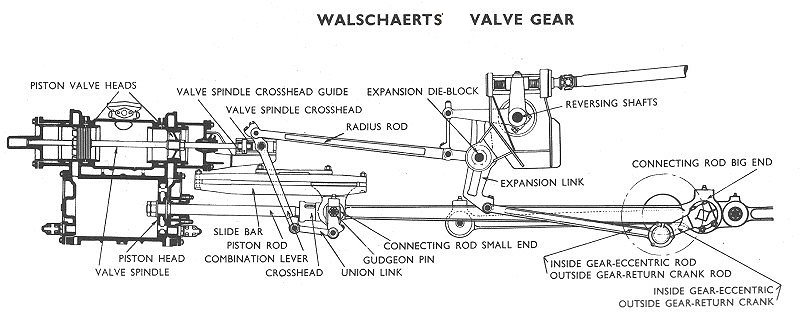

The switch between either direction was operated by a valve spindle and a set of bars and pistons that was empowered by the cylinder piston itself

The cylinder piston is fit to a hinge that is installed on a slider bearer that fits a slider bar.

This is know as the cross head. From out of the cross head, a connecting rod is liked between the sliding section and a wheel tap. The wheel tap is placed out of the center axle.

When the cylinder starts to move on and back the motion and force was exchanged to the wheel tap, causing the wheel to revolute around on the axle of the wheel.

More wheels were coupled by coupler rods on the same principle as the main driving wheel.

This resulted in a boosted force on the wheels creating an hugh amount of force that was able to haul heavy freight. This force is exchanged to the coupler and the motion that is generated by the steam power and the force of gravity that create adhesive traction between the rail surface and the revolution driving wheels of the engine. The trick now is to start to move the train without spinning or slipping wheels of the engine, if the wheels does not slip or spin, you have overcome the massive weight of the train. When the train is moving. kinetic energy is absorbed in the weight of the train and will cause the train to roll on after the cut-off the regulator, reverser and either the use of the brake as well.

To maintain and drive a steam locomotive requires a lot of blood, sweat and tears.

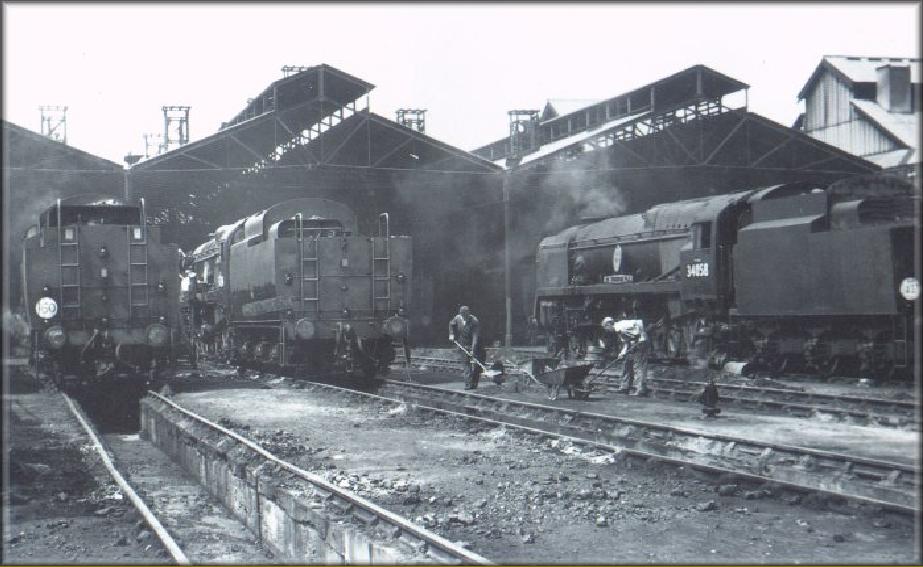

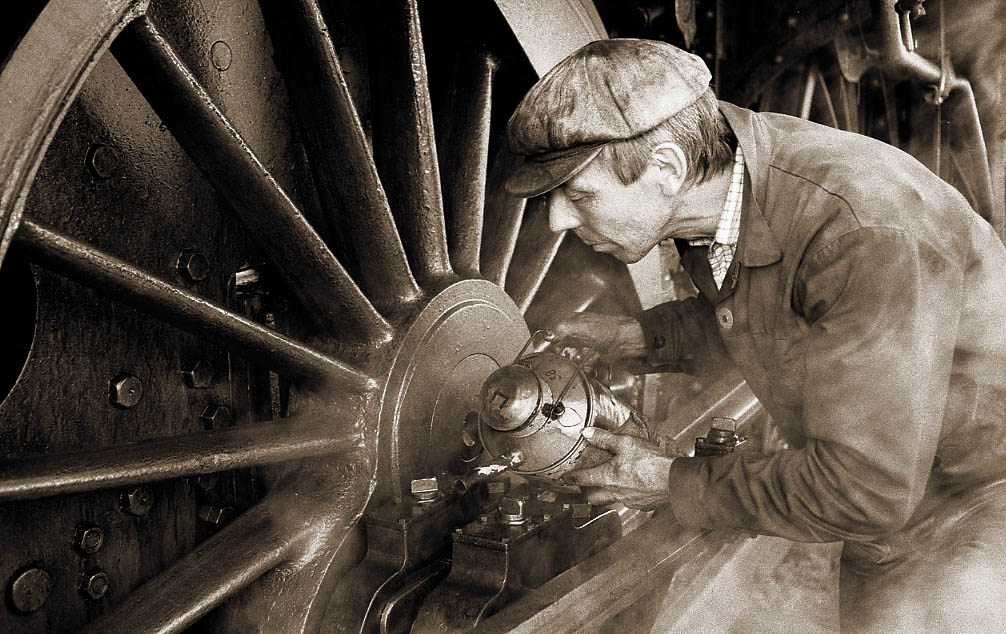

Driver and fireman kept up the pressure, It was a mental heavy stressful duty railroad man has to achieve. A fire man was shovelling 2000 lbs. of coal at 50 km / 35 mile. When the engine is stationary. all motional rods, bars, levers, pistons, axles and more needed to be lubricated.

This has to be done in between two runs or shifts.

They always worked together as a team., the fireman was subject to the driver and was the drivers student. The driver was responsible for the proper education the fireman had to learn. After a several years the fireman became a driver and a fresh fireman was dispatched to the new driver.

Is this virtual footplate comparable with the original footplate? Yes and No.

Yes, because you will learn the most basical aspects you have to deal with including the signal aspects and theoretical aspects. when you in a run for about 60 minutes an a derailment occurs. you will become set up and irritated as well. Because you now can start over again

But it tells you exactly what (not) to do next time. You taste the thrill, the dream, the desire, the imagination, the sounds, the visible behaviours and the small feeling.

No, because the lack of the rough works, the ambience, the smell, the dirty hands and faces, the sizzling steam leaks, the feeling, pain and the passion.

2.02 – The start of your shift

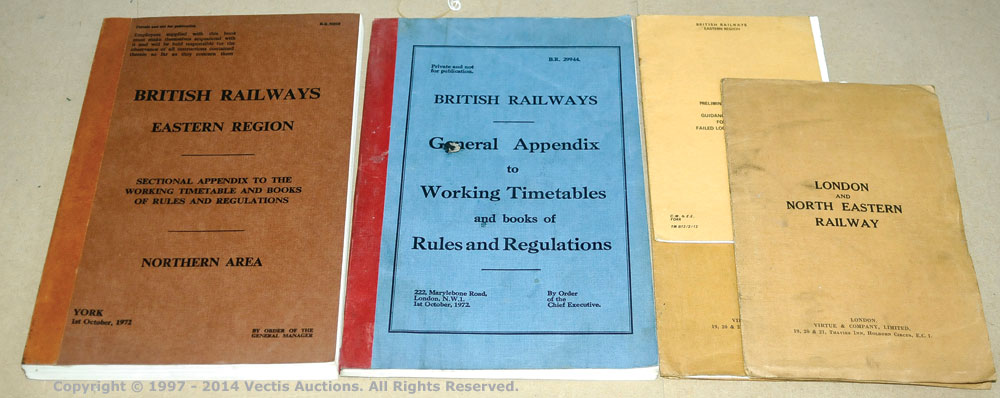

In every branch, work, office, shop or even in private life, paperwork is always part of the daily life. It documents all information you have to deal with. The railroad companies does have an hugh amount of documents you need to know prior to the start of your shift and even prior to the start of your work. Underneath there is a certain amount of issues you need to know. Even in TS2015 you better document all of the route, engines and trains you are going to drive.

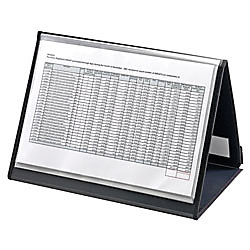

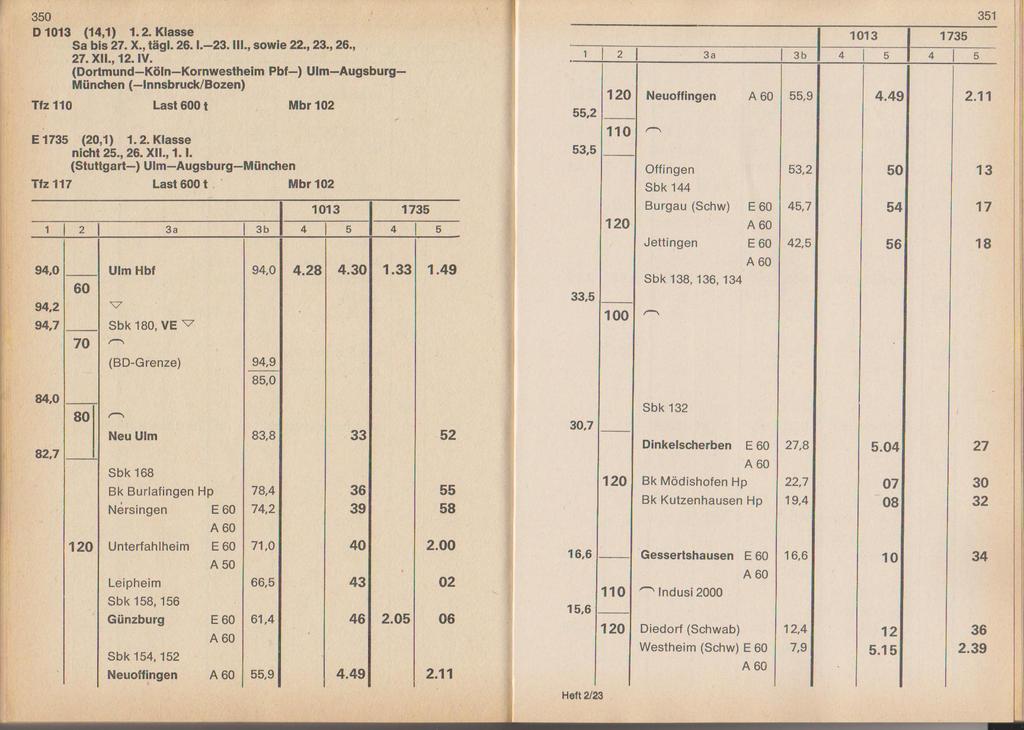

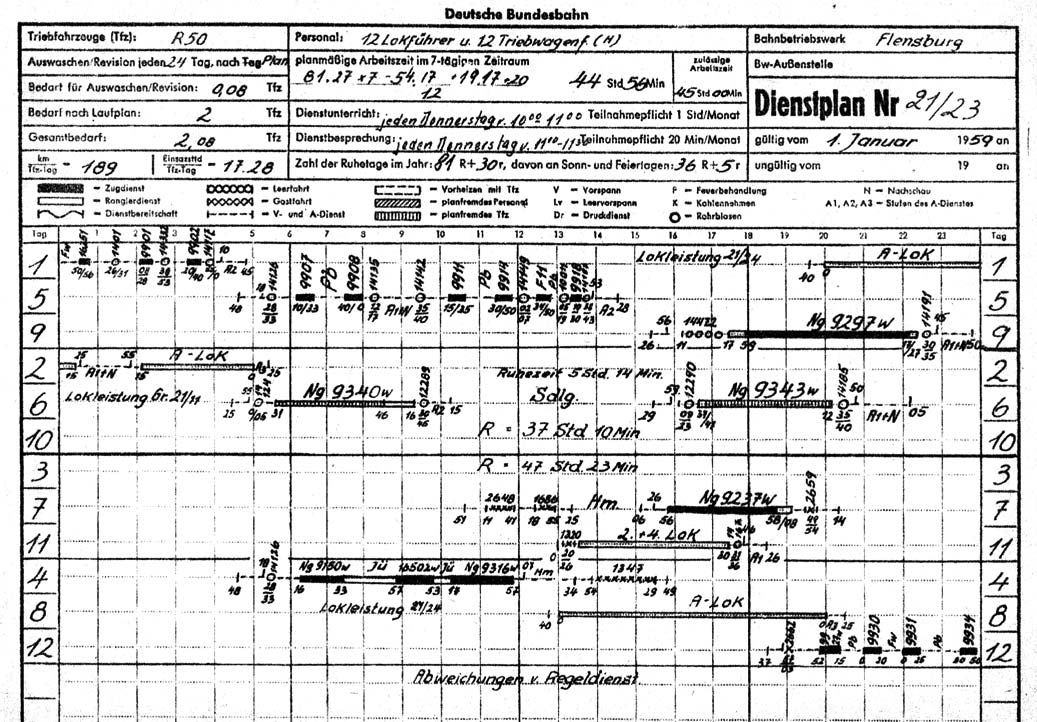

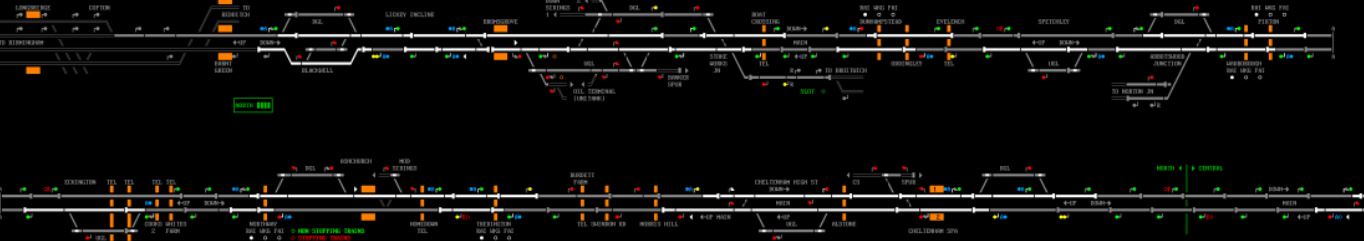

An original German Buchfarhplan. German Railroads uses original but edited “Buchfahrplans” (Trip Notebook) for all their routes available for MSTS. Put this “Buchfahrplan” at the easel and you have direct access at the “Buchfahrplan” during your run.

If any information available print it out and put information into binders for direct access when running a scenario. You can also use a 2nd PC or laptop containing digital documented information such as PDF or DOC (or other file formats) as long as you are able to access this information necessary for your run or scenario.

First of all, when arriving at the depot to start your shift, you report yourself at the dispatchers desk. In the case of TS2015 you choose your “job” to drive.

After making your coffee and receiving all equipment you now set of to your engine for preparation.

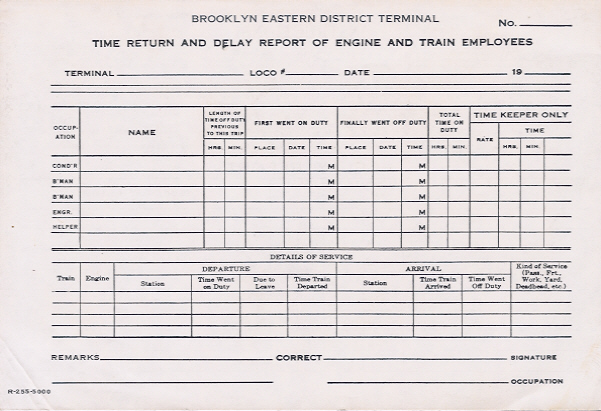

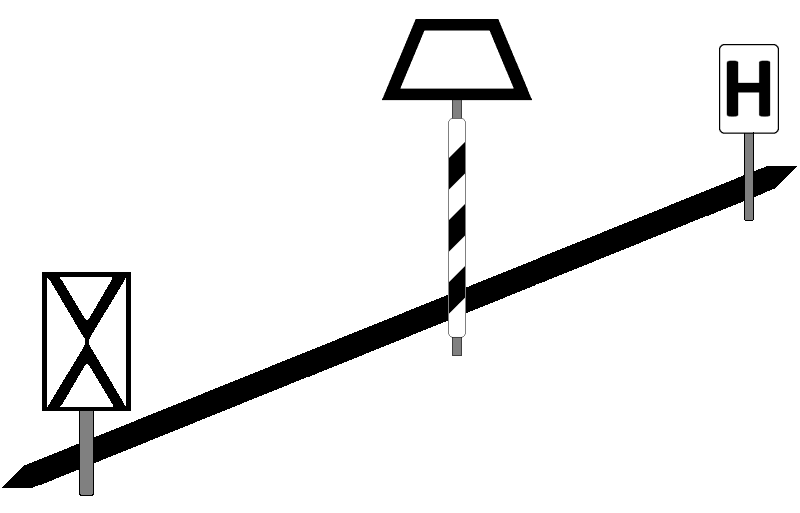

Trip notice booklets carries the time schedule of specific engines that are dispatched to a specified service. The service number at BR is often the same number as the headcode that you need to use on your engine when you are driving a diesel or electric engine. A steam locomotive needs to set the lamp code properly. Later on headcodes were put at the smokebox door.

The trip notice shows the specific time table that is set for the mentioned shift. In the trip notification the headcodes can change, but the shift code remains the same.

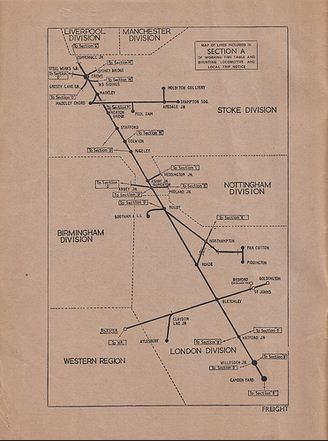

Each region has their own set of trip notice booklets that contains all the schedules time tables. Often more booklets are in use depending the types and classes of trains.

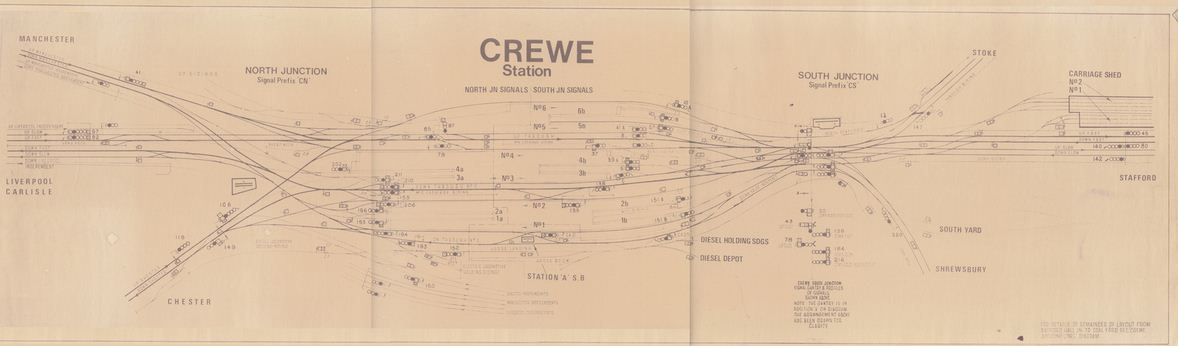

Each trip notice booklet contains a set of charts showing a global route lay-out of the specified region and specified the track lay-outs of each station, junction, yard, workshop or depot that is situated in that specified region. These lay-outs contains information about track length, signalling issues, catch points and more which is valid every track separately.

A marshal list is almost equal to the trip notice. However a marshal list mostly is valid for one day. TS2015 has an option to use a Marshal list when creating a scenario. When the scenario is running the marshal list can be overviewed by pressing [ F1 ] and appears at the left fly out.

Some scenario’s contains a additional file to print the list to recreate the reality more closely.

A marshal list is created with a type writer and can be edited by hand by the signaller or dispatcher. When a change is made the driver himself will made changes to the marshal list.

Next: An example of a written train order that contains all information that affects your run of shift. Last: The shunt list tat contains all information concerning all shunting trains, empty stocks, parcel trains, etc, etc.

After entering the office and you have take notice of all works for that day to take place you just take notice of every memo that is in execution and possible will affect your shift as well. Getting this information is always a part at every shift no matter the day of type of train you drive.

The dispatcher and can also hand out a special order for you that will completely change your expected shift as well.

The dispatcher keeps record of your progress. This means track acknowledgement, medical history, licensing, hours of working, day offs, holidays and other personal issues of your concern.

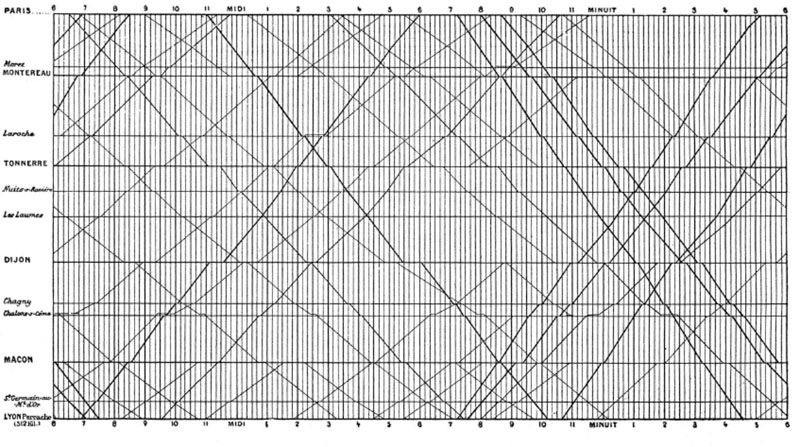

Dispatchers, signallers and time table developers will work with these diagrams. The diagram shows a combination of time / route and station. Each station is mentioned at the left in sequence of the route. while the time line goes from left to right. The angled lines shows the path a train is running and shows speed. time and endurance of that particular train.

The dispatcher also memorize every change into a record that is kept in the depot office about every driver and fireman and other employees.

An employee record

When you have take notice of all of your shift, train notifications and additional reports that is valid for the route, train and stations you have to encounter you set of for your engine to prepare the engine.

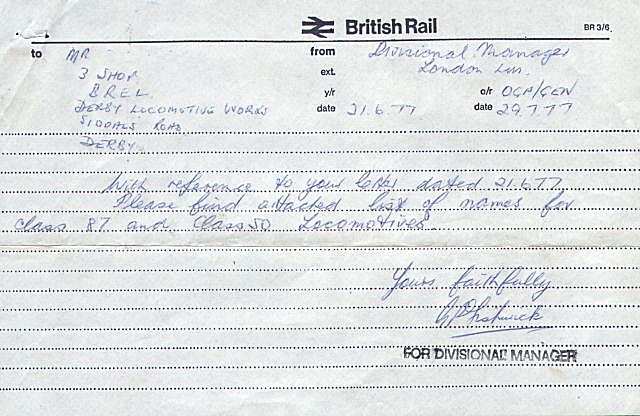

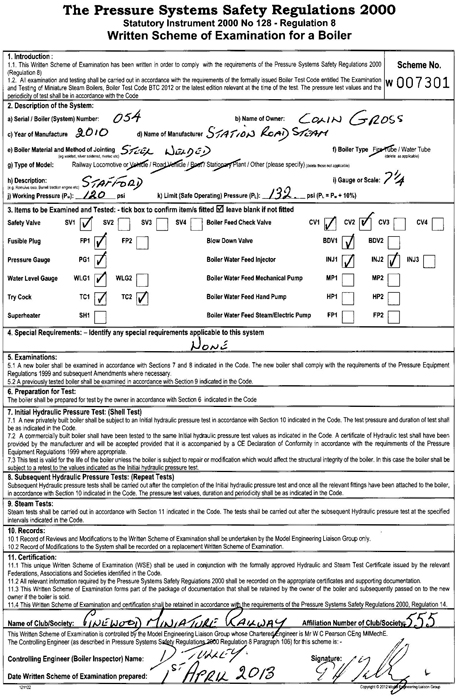

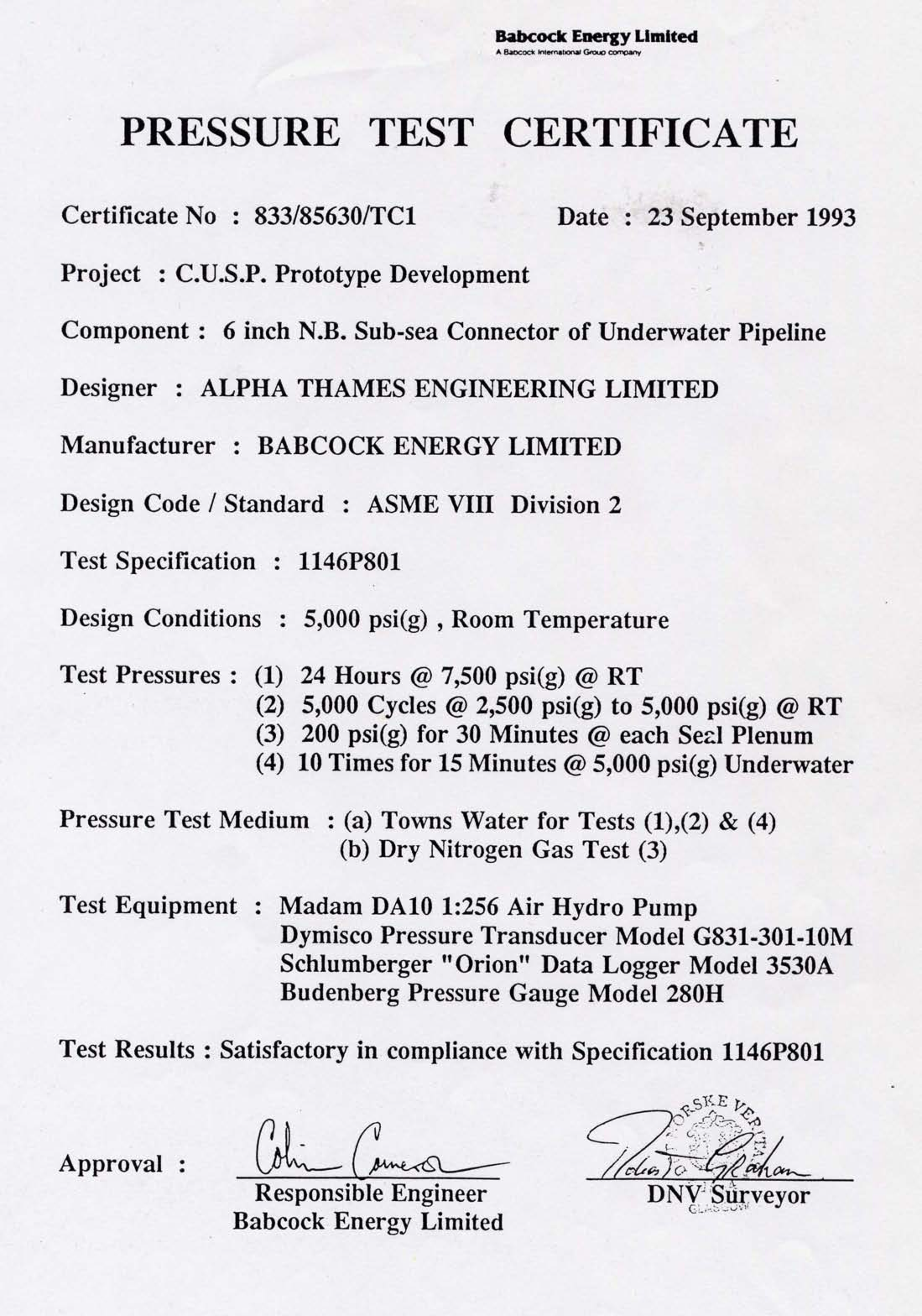

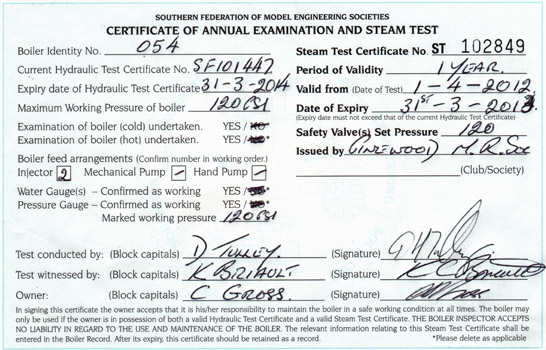

Every engine got a logbook and all the certificates of all pressurized equipment and boiler certificate. This logbook needs to be filled out after every run that records every discrepancy and aberrance you encounter during the run. This logbook is always given to the dispatcher or to the crew that takes over the engine during a run.

The engines certifications and documents are mostly stored at the depot where the engine is located. Binders contains all documents for each engine specifically.

Boiler certificates and certificates that guarantee the state has the keyrole for the use of an engine to enshure the safety of driving and pressurisation of the boiler itself. The approval of a boiler is executed by govermental departments and is part of the national safety regulations which is common for every country running a railway company.

2.03 – Preparations to fire up and igniting the fire.

203 Preparations to fire up and igniting the fire

Before you create the fire you need to know the different types of steam. Every type of steam got its own specifics. Depending the type of locomotive you use will also depend the type of steam you need.

Wet steam is the most common form of steam actually experienced by almost all flora. When steam is generated using a boiler, it usually contains wetness from non-vaporized water molecules that are carried over into the distributed steam. Even the best boilers may discharge steam containing 3% to 5% wetness. As the water approaches the saturation state and begins to vaporize, some water, usually in the form of mist or droplets, is entrained in the rising steam and distributed downstream. This is one of the key reasons why separation is used to expell condense from distributed steam.

Saturated steam is actually dry steam which occurs when water is heated to the boiling point (sensible heating) and then vaporized with additional heat (latent heating). If this steam is then further heated above the saturation point, it becomes superheated steam (sensible heating).

Saturated Steam (Dry). Saturated steam however occurs at temperatures and pressures where steam (gas) and water (liquid) can coexist. In other words, it occurs when the rate of water vaporization is equal to the rate of condensation.

Advantages of using saturated steam for heating has quite a number of properties that make saturated steam an excellent heat source, particularly at temperatures of 100 °C (+/- 200°F) and higher.

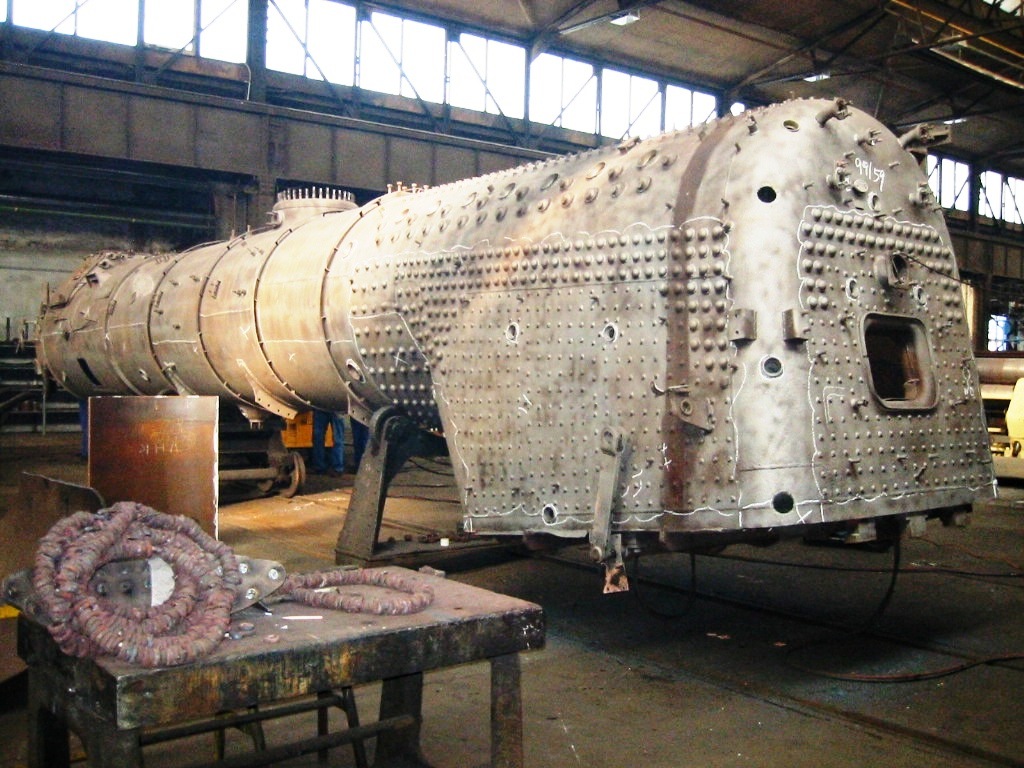

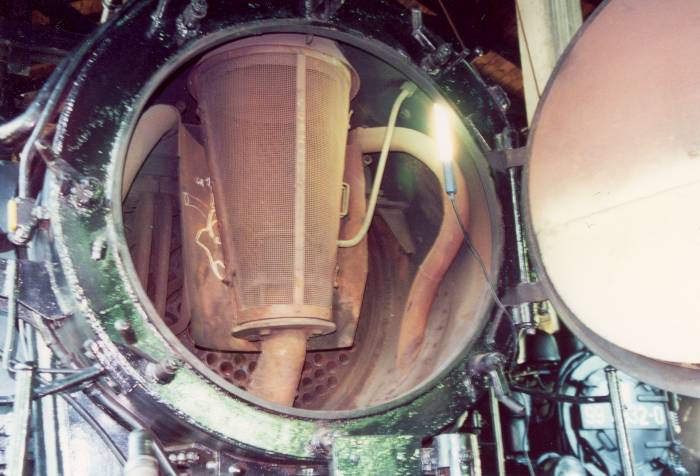

Superheated steam is created by further heating wet or saturated steam beyond the saturated steam point using super heater elements mounted in the boiler tubes. This yields steam that has a higher temperature and lower density than saturated steam at the same pressure. Superheated steam is mainly used in propulsion/drive applications such as turbines, and is not typically used for heat transfer applications.

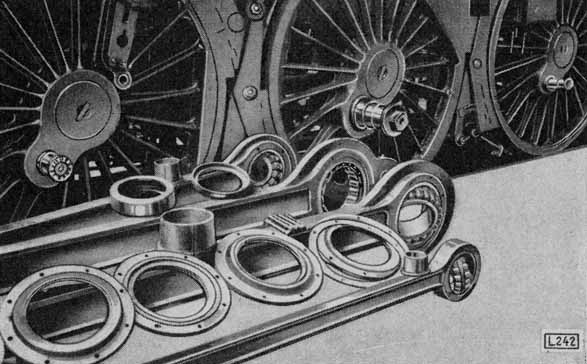

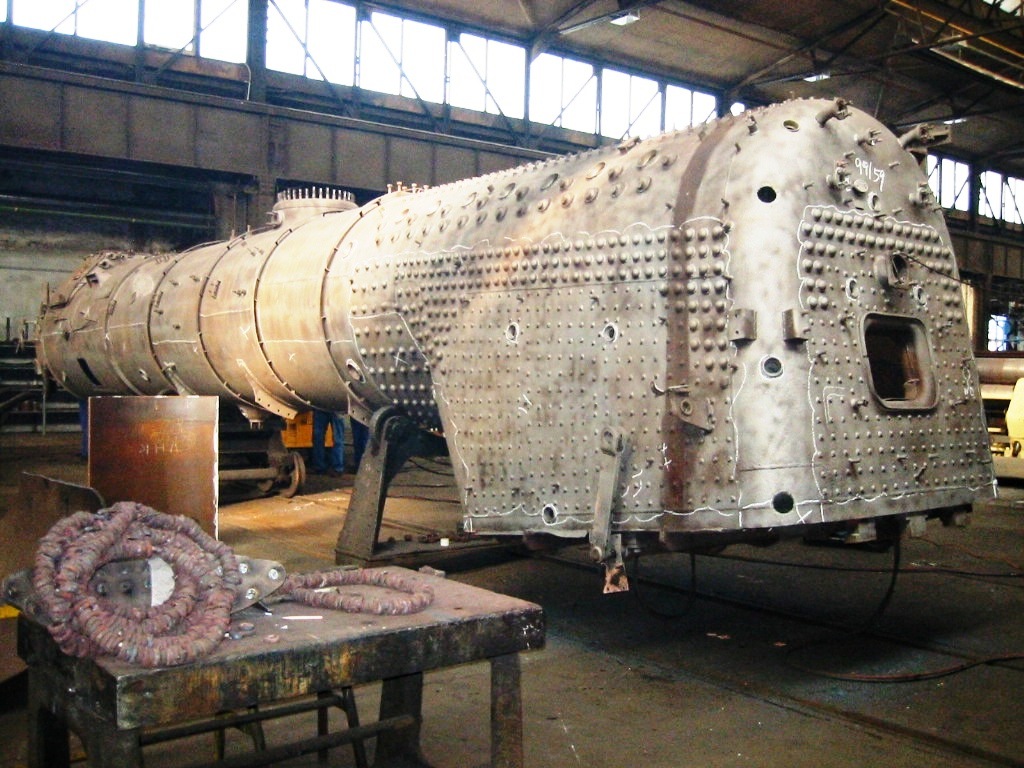

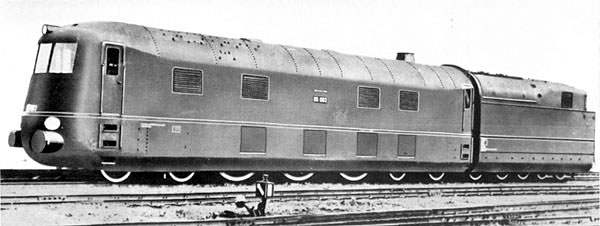

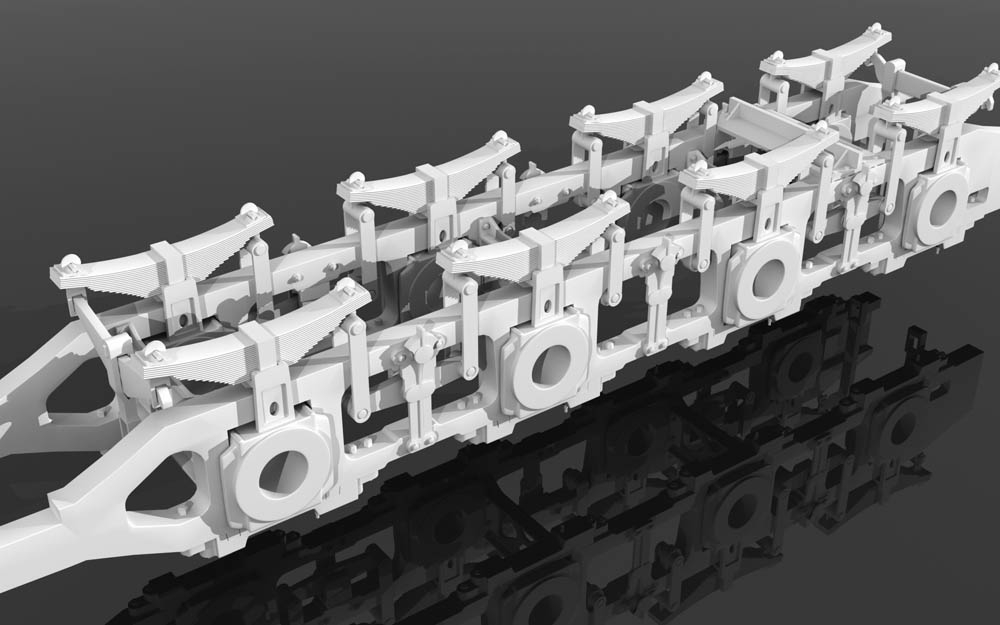

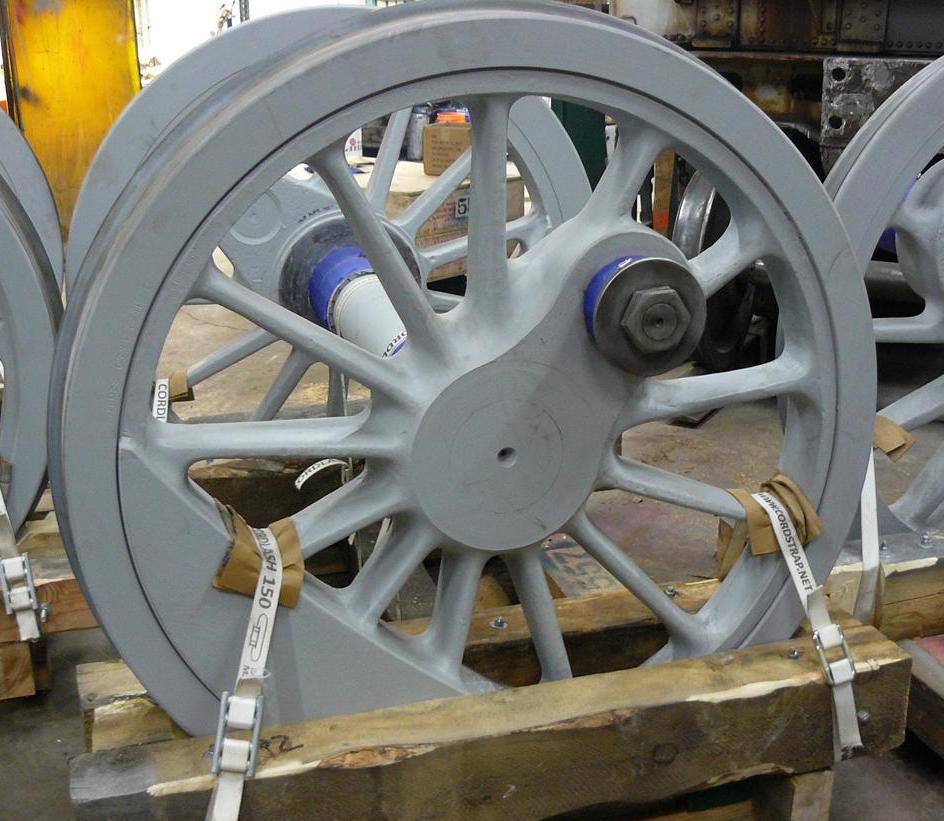

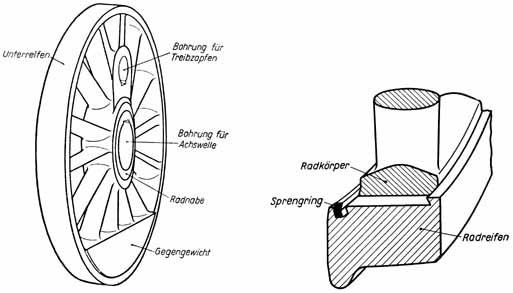

Newly constructed super heater elements ready to install.

It is advantageous to both supply and discharge the steam while in the superheated state because condensate will be generated inside steam-driven equipment during normal operation, minimizing the risk of damage from erosion or carbonic acid corrosion. In addition, as the theoretical thermal efficiency of the turbine is calculated from the value of the enthalpy at the turbine inlet and outlet, increasing the degree of superheating as well as the pressure raises the enthalpy at the turbine inlet side, and is thereby effective at improving thermal efficiency.

After you arrive at your engine, you start to walk around the engine and check all pistons, rods, hoses, wheels, cylinders, etc. When you take over the engine at a station mention train movements aside your engine. Check also if the rail shoes are in position at both sides of a set of wheels.

Get into the engine by pressing [ 2 ] and press the [ / ] Button to set the handbrake.

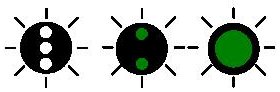

The hand brake of a Just Trains 4MT and the hand brake of a Black 5 (Port Road).

At some advanced engines such as the Just Trains 4MT and 6MT you see the lever spinning when pressing the [ / ] button.

Preparing a steam locomotive in cold state takes a lot of time. First of all take away the chimney cover or chimney lid and close all valves to keep the pressure when the pressure starts to rise. Prior to firing up you test the water level and the water scope if these instruments are working properly. This is a major task with highest priority prior to firing up. An empty boiler causes an boiler explosion which is mentioned later on in this guide.

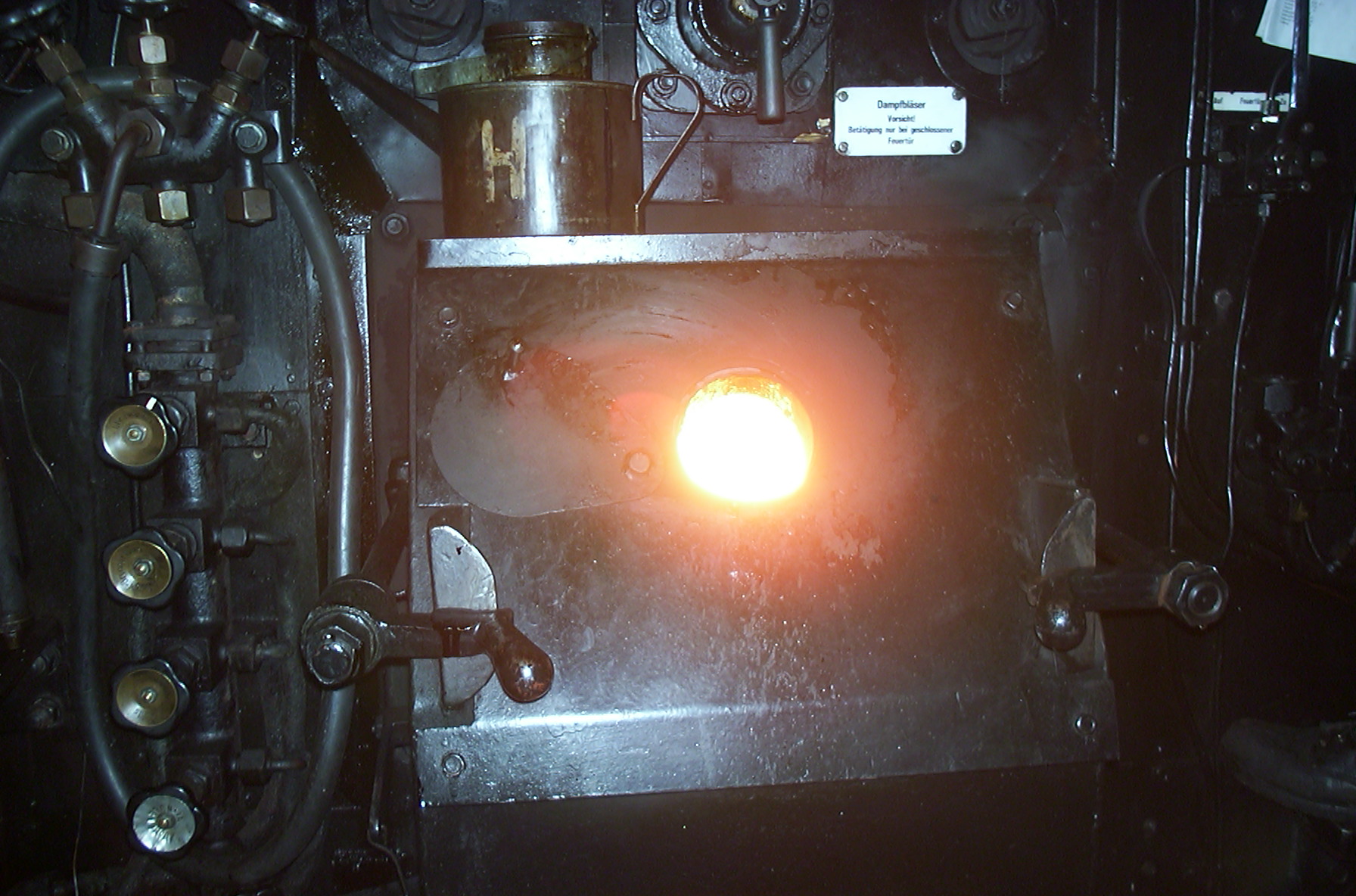

After you have done this test and water is surely in the boiler at the right level you are now ready to check the fire box. with a light you watch and inspect the fire grate closely if all bars of the fire grate are properly installed in place.

Then you build a pile of wood all over the fire grate using old sowed pallets and old timbres that are easily to handle.

- After the fire box is filled up with these bricks of scattered pallet wood, you now take a bucked of gasoline and some old shreds.

- You now put these shreds in the bucked of gasoline and submerge these shreds completely in the bucked of gasoline. Be sure these shreds are drowned with gasoline.

- Take the drowned shreds and wrap these shreds at some sticks or timbres of wood.

- Take a match or lighter and ignite the edge of a drowned shred at the wooden timbre. Wait a little and see the fire increasing.

- When the fire now starts to rage on the shred, you now throw this timbre with burning shred

into the pile of pallet wood under the fire arc. - Repeat the sequence 2 or 3 times but you throw the raging timbre to the right either to the left.

Now the fire is on and you need to watch the fire closely, Wood is a good fuel to fire up, but depending the state and sort of wood the fire can vanish at once then you have to start all over again.

2.04 – Proceed firing and creating pressure

Prior to the first run it is necessary to build up your pressure and fire. A good fire is one of the sources for a good production of steam.

First of all press [ N ] to increase the blower. This action increases the air flow by the develloping under pressure in the smoke box caused by the blower. The function of the blower is explained later on.

Press [ M ] to open the air damper valve/hatch under the fire grate at the ash pan.

By opening up the damper(s), the air flow then has free access through the fire grate which flows through the boiler (tubes). The damper are mounted at the rear and front side of the ash pan. Regarding the lever you will open the rear and / or frond damper when both dampers are installed.

Some engines uses a hand wheel and some uses a lever or handlebar. The hand wheel is however more precise and sophisticated in order to regulate the amount of air flow through the damper(s).

Some 3th party engines like the 4MT and 6MT Clan Class from Just Trains Expert Line uses a hand wheel to regulate the dampers. These requires special skills to drive this amazing engine properly and these skills are hardly needed at TS2015 as well. If you are not dealing carefully as it should be your engine will stuck on the run. To have the full understanding about the operations of the 4MT Standard Class and 6MT Clan Class, refer to Chapter 15 in this guide.

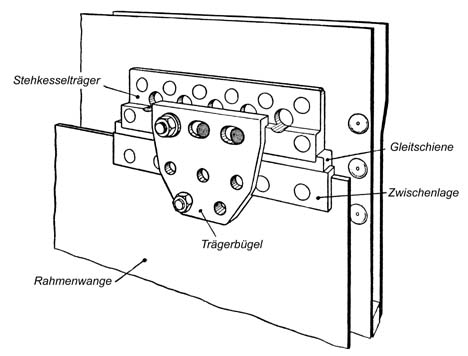

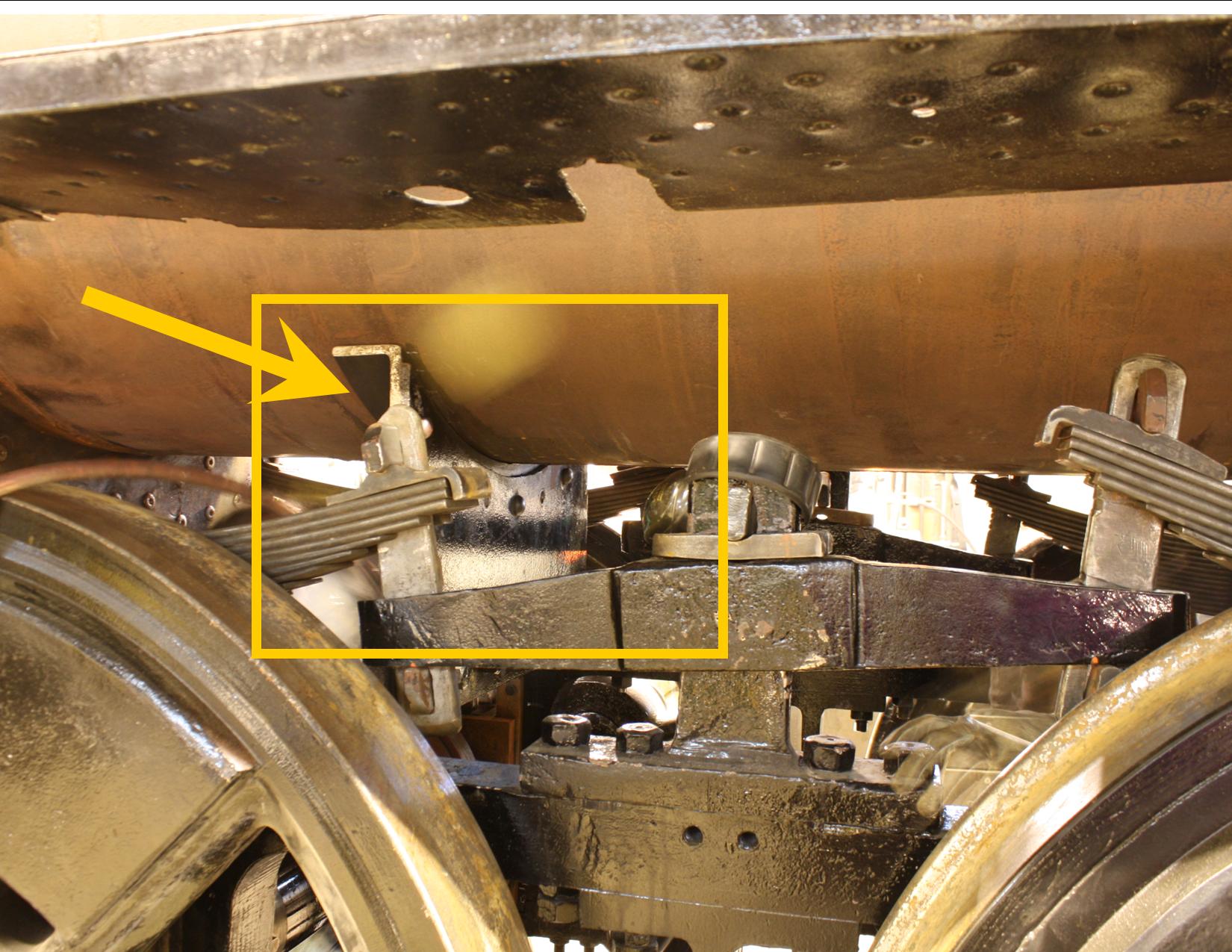

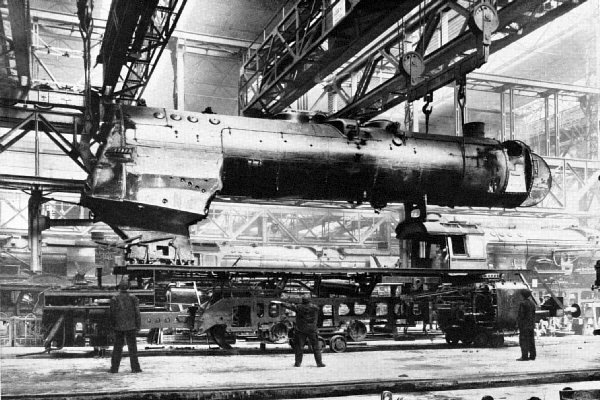

Now underneath the footplate there are some hatches to open up. This is not simulatied in TS2015, but in practice: you have to open up the that hatch and unscrew the nuts (if available) under the floor of the footplate just in front of the fire box. These nuts are not present on every engine. You now unlock the boiler to “move” or “slide” parralel along the frame bars of the engine. This prevent the boiler and frame bars to bend when firing up.

At both sides of the fire box a slider rail is mounted and slides over the frame bar section carrying the boiler. The boiler will expand in lenght by the increasement of the temperature. The material expand and at the end when the boiler is in hot state the boiler lenght has increased by about 3/4 inch when the engine is fired up after approx. 8 hours. When the boiler should be locked up by these nuts, the boiler and frame bars will bend.

The boiler has a fixed mounting point to the frame bar underneith the smoke box. This means that the boiler is supported at two places. Underneath the smoke box as a fixed point and at the slider bars at the side of the fire box or ash pan frame which is moveable by sliding over the frame bar, carrying the boiler.

The weight of the engine is now divided over the frame bars and wheel springs which are balanced out regulating the axle pressure.

Now the first measuremets are taken starting an engine in a warm state.

You now have to stir up the pressure and fire to get ready for the run.

Be aware if the conditions are normal, the steam engine will be under pressure after about 4 hours of firing up. The pressure is at that point not powerfull enough to drive on, but is useable to turn on the blower. This time period is based on regulair engines like a Black 5. Tender Engines needs lesser time to be pressurized.

Be shure you have open up the dampers, the blower and check the fire.

Use F4 to check the coal rate on the fire bed. If it is lesser then 75% start shoveling.

As you have done it all right the blower should be working right now.

Press [ F ] to open the fire box. (Press Shift – [ F ] to close)

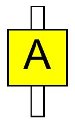

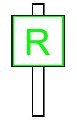

Press [ R ] to increase the shovel rate. (Press Shift – [ R ] to decrease and stop)

However this is only to be done when the engine should be ready and under pressure in the shortest period of time. Though this operation to produce steam this fast, is far of the proper method to fire up the engine.

The boiler will heat up too fast and could cause servere problems later on damaging the boiler. The steal or brass will expand too fast causing tiny invisable cracks in the boiler material.

It is necessary to use the blower in order to avoid blow back, pressure drop and fire extinguishing.

Start up of a steam locomotive. Recorded in Paekakariki, New Zealand

Be shure your blower is working right now, otherwise you’ll have the risk of that blow back.

Keep the fire between 70 – 75 % !! Not exceeding 80%.

Press F4 to see the fire amount in the HUD display.

Press F5 to see the firemass in the text information left on top of your screen.

When you should exceed the amount of coal in the fire box, the chance of slack forming is increasing. At advanced engines like the Just Trains 4MT and the 6MT Class, this is simulated.

Coal slacks are unburnable contents of coal which will melt together blocking the air flow in the fire grate.

2.05 – Lubricating, an important issue

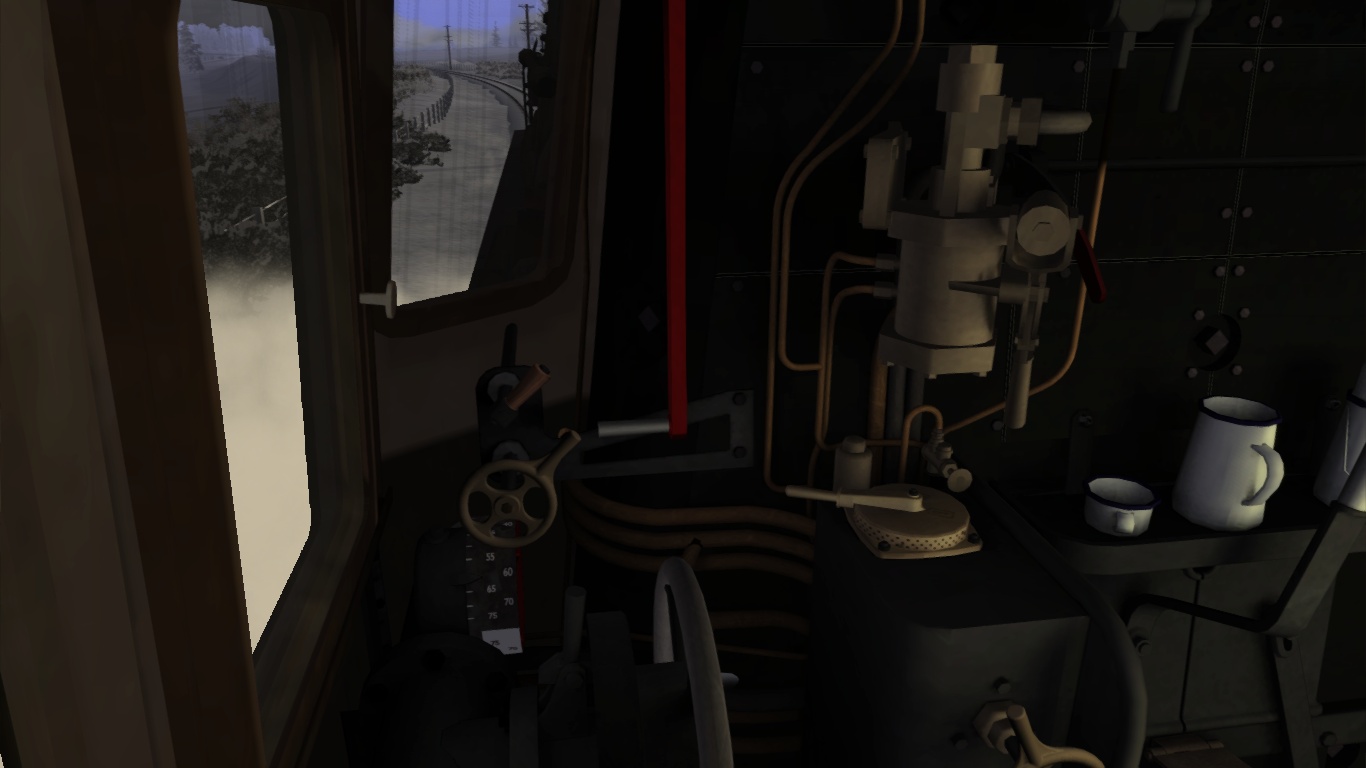

The majority of the TS2015 and 3rd party engines does not support the lubrication process.

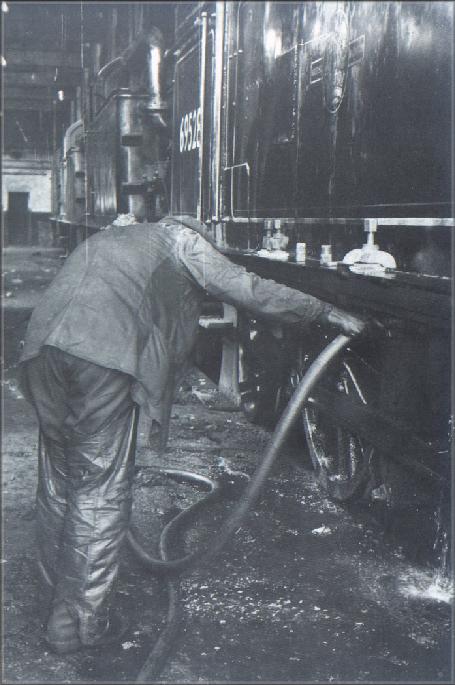

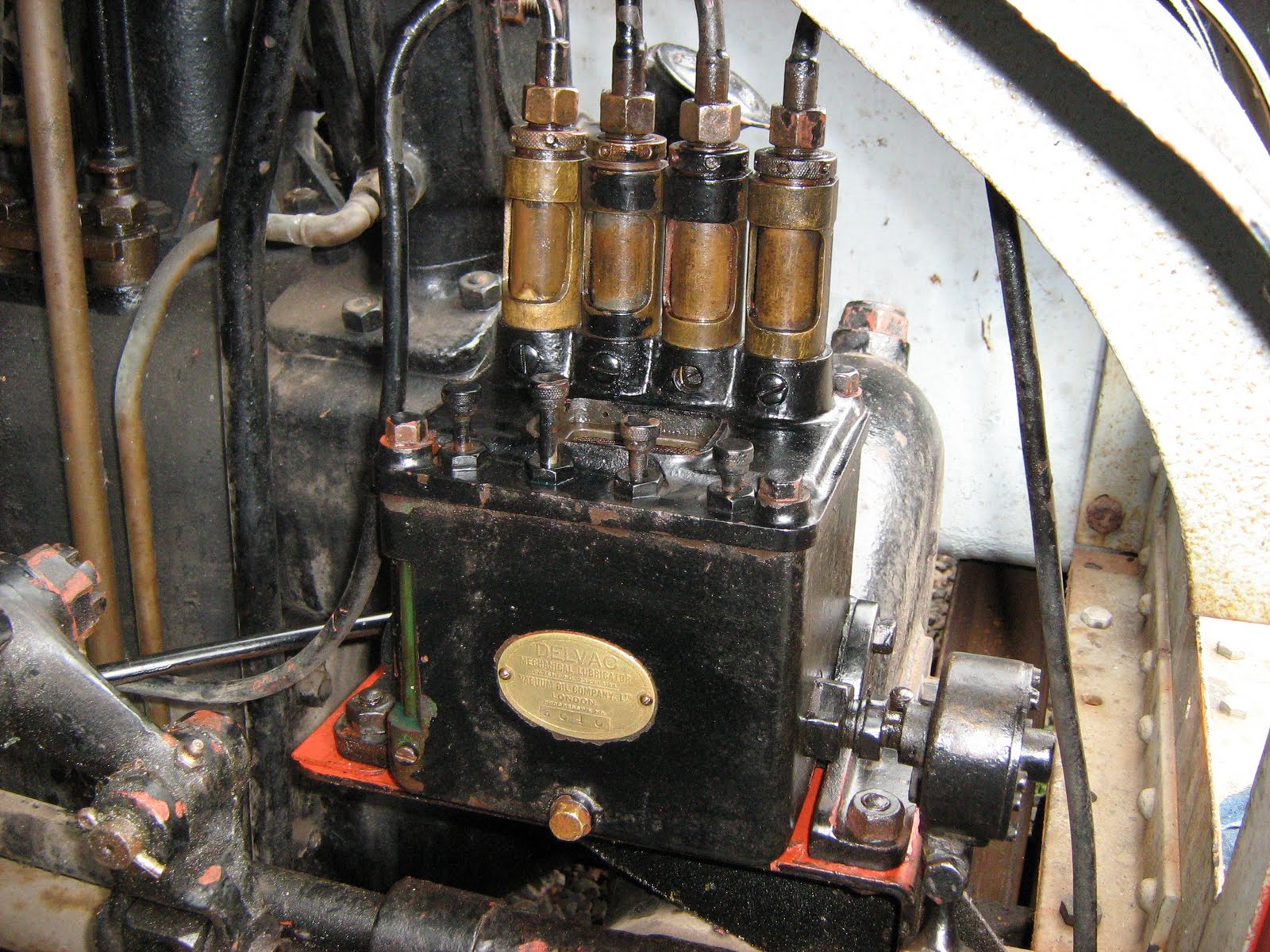

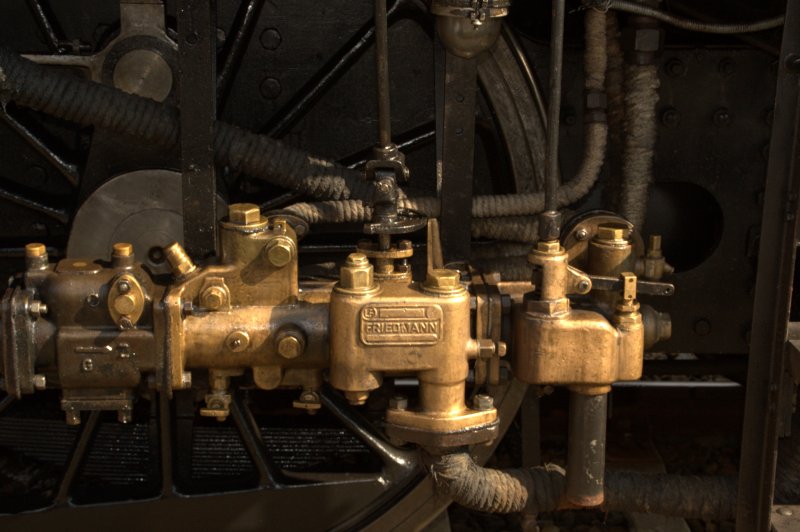

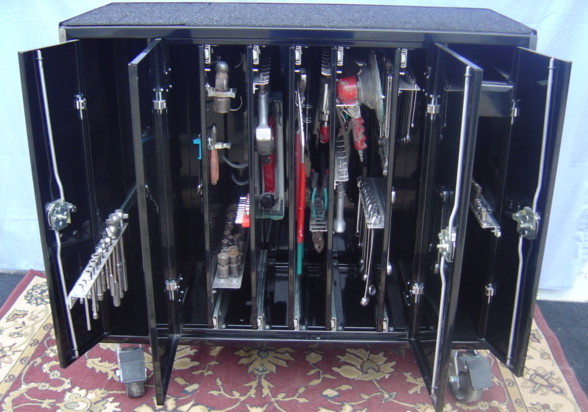

Some 3rd party engines does have a lubrication process and within their scenario’s it is even required to use the lubricator prior to departure. The lubrication by hand, using an oil can, hand pump or grease injector for every rod, axle, bars, pins, etc, are not simulated, only the lubricator itself is operational.

Third party developer and software producer Just Trains provides the lubrication process with the Advanced 4MT and 6MT.

In order to use the lubricator make sure the engines handbrakes are set.

If you own a 4MT or 6MT from Just Trains, the lubricator is operational prior to the run when the hand brakes are set by pressing [ / ]. Then press [ Y ] for about 5 seconds.

Refer to Chapter 21 in this guide for more about the JT 4MT and 6MT Advances series.

Oil is used to lubricate all motional parts at the engine. Motion is substitute to friction.

Friction causes heat and when steel becomes too hot, the steel will encounter severe damage. Axles and pistons needs to be lubricated by every time occasion. The driver checks always the temperature of the pistons, rods and bars due to frictional movements.

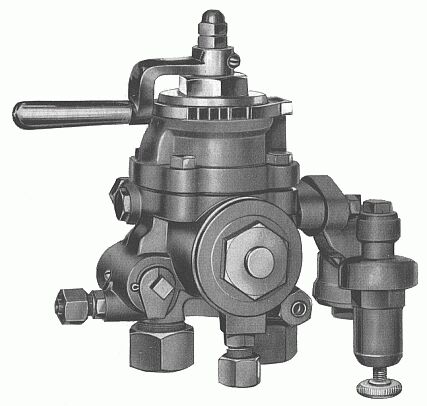

During the run, a rod is installed between the piston of the last axle and the lubricator. The rod operated the mechanical oil pump at every rotation of the last driving wheel. The mechanical pump then distributed the oil using a small brass pipe to the “unreachable” motional parts independently from each other.

The amount of oil for each motional part can be regulated separately depending the need and quantity of oil at every swing the rod is operating the lubricator.

When the engine is stationary, the lubricator once and a while needs to be operated manually. Though after a period of time and prior for the next run, the lubricator spindle needs to be rotated manually as well to ensure the lube reaches of all the connecting points and surfaces of the motional parts.

Depending the type of engine, railroad company and country you will start to lubricate when the boiler pressure starts to rise. All motional parts has to be lubricated. Once started to firing up, the oil cans needs to be filled up with the proper oil or grease. You just cannot use all sorts of mineral oil. The grease or oil must fulfil industrial lubrication requirements. Mostly this is special oil with an cohesive number.

To lubricate an engine different type of oils ar used. The oil cans at German engines are assigned with colored lids for recognition.

1. Cylinder Oil (blank lid with a red A)

Oil (cohesive value: 1000) used for cylinders only, it can handle temperatures up to 400 degrees C.

2. Thick Oil (red lid)

Oil (cohesive value: 1000) used for water and air pump and can handle temperatures up to 400 degrees C.

3. Thin Oil (yellow lid)

Oil (cohesive value: 220) used at pistons, axles, rods, motional bars, levers, lubricators.

This oil is not suited for high temperatures, but can stand up to 130 degrees C.

4. Used oil.

A mixture of all oils to lubricate couplers, simple motional bars, truck pins, springs and door pins, coupler bars between tender and engine. This oil is not suited for the named equipment in the mentioned lines 1, 2 and 3 above.

5. Polishing oil.

A mixture of petrol, thin oil and think oil. This oil is slightly warm when used.

This oil is to polish the plate work of the boiler and engine. This will also preserve the plate work of the engine and prevents corroding and creates a thin layer of oil on top of the plating reflecting a half matt glossy shine effect by the sun glare or light poles.

6. Grease.

Used to lubricate buffers, coupler pins and bars, screw bars, truck studs, boiler sliders and locker nuts.

The melting of the white metal could occurred on the taps and pins connecting the pistons, rods and bars.

TS2015 simulator is quite basic, but within the range of TS2015 you can still achieve many issues concerning driving a steam engine as it should be.

2.06 – Operating the air brakes

Pressurizing the brake pipes is required to meet some important issues. After pressurisation of the pipes and reservoirs, the brakes can applied in order to release the hand brakes. Prior to that, rail shoes needs to be in place blocking one wheel of the engine. This prevents the engine (also rolling stock) to move uncontrolled, creating a run-away train.

To operate the brake pump, press [ J ] to start and run the pump or ejector.

Press [ Shift ] – [ J ] to shut down the pump or ejector. Air is filled in the air reservoir and helper reservoir.

During the run, use the small ejector to keep the brake pipe pressurised. Engines equipped with a steam powered air pump runs automatically when the valve is closed. the pump remains operating because the valve does not close completely in order to keep the brake pipe pressurized.

A small bypass or small gap lets steam flow into the air pump that runs on low frequency.

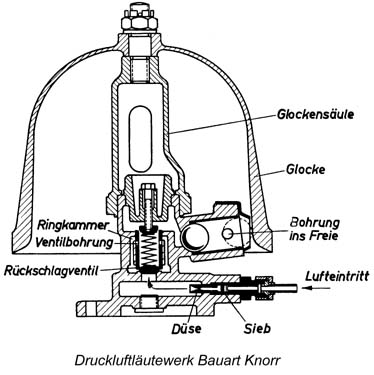

This continuous operation causes the specific sound at the Knorr air pump

To fill the brake pipe quickly, use the large ejector. The large ejector does not work on all engines, but in most cases still static present. Do not forget to turn the large ejector off otherwise you will have loss of steam pressure.

When you are driving, keep up the pressure in the brake pipes by slightly open up the small ejector.

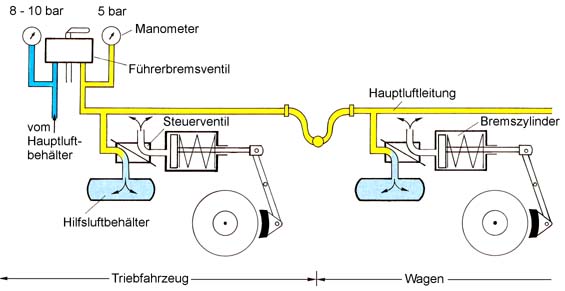

The pump feeds the main reservoir with compressed air. The main reservoir keep the compressed air to feed the brake pipes of the train, each wagon or coach does also have one main reservoir to support the brake system of the wagon or coach. Via a triple-vlave the brake reservoir, helper reservoir and brake pipes will be filled up.

The 2 steps water pump works quite the same as the water pump

The helper reservoir takes care of the direct operation of the brakes. When the air has being released out of the main brake pipe, the helper reservoir kicks in and pushes the brake shoes directly on the surface of the wheel rim. At main line engines hauling express trains, a 3-way or 4-way valve is installed on which the airflow is divided to regulate the pressure to the brake shoes to give the right amount of pressure to slow down a express train at high speed. This valve is only operated by hand and is mostly installed underneath the footplate at the driver’s side. At coaches and wagons this manual valve is also installed issuing the same function, but only for the use on the wagon or coach itself.

A steam engine has a divided pair of brake shoes installed to create a balance in the wheel rims of the driving wheels. The bars underneath the engine will also divide the brake power to each wheel separately, because not all axles uses the same brake force on slowing down.

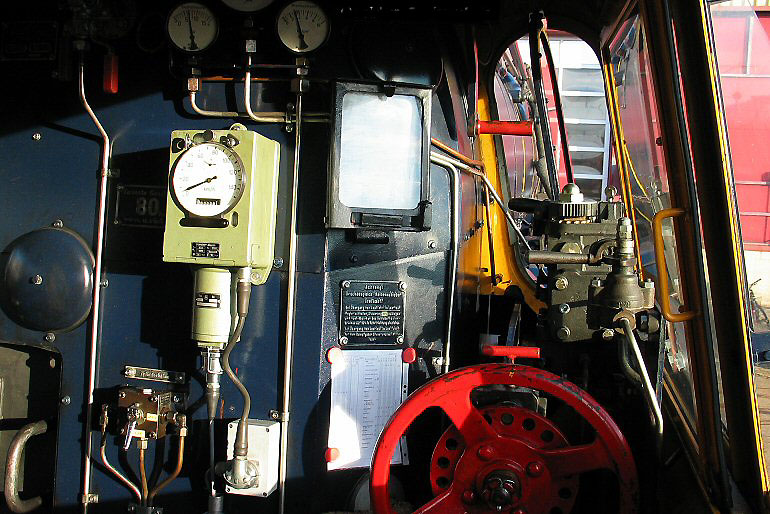

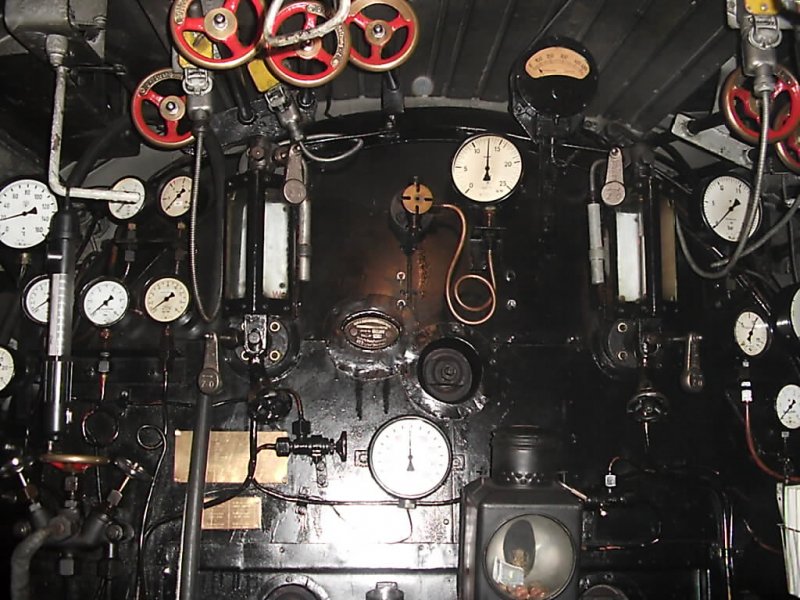

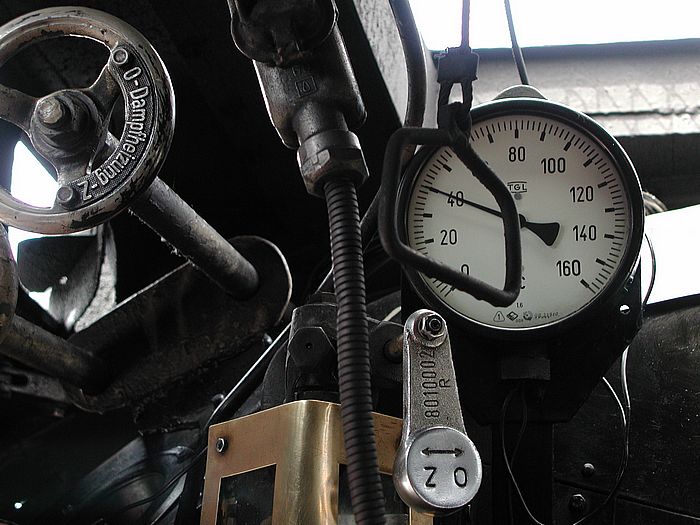

The air pump is mostly operated by an manual valve connecting to a hand wheel just above the regulator close to the front window at the drivers side.

The counter-pressure brake (German: Gegendruckbremse), also named the Riggenbach counter-pressure brake after its inventor, Niklaus Riggenbach, is a dynamic railway brake on steam locomotives that brakes the locomotive using the driving cylinders. In doing so it reduces wear and tear and overheating of the driving wheel tyres and brake blocks and enables a continuously high brake force to be applied. The brake works by using the cylinders as air compressors and converting kinetic energy into heat. Steam is emitted during braking but this does not come from the boiler, it is produced by evaporation of water used to cool the cylinders.

The main part of the system is piping and regulation of atmospheric air drawn into the cylinders, into which cooling water and oil is injected. To use the cylinders as pumps necessitates complete reversal of the normal gas flow. Atmospheric air is drawn through the steam exhaust and compressed air ejected through the steam inlet. A separate chimney is provided, usually behind the main chimney, to exhaust the compressed air without increasing flow through the smoke box (which would cause increased draught of the fire).

Water injected into the incoming air evaporates during compression, carrying away much of the heat generated. Oil is also injected into the incoming air to maintain lubrication of the cylinders and contribute a minor cool down together with the mixed water. Though the use of water may not be exesive while the cylinder will encounter a drop down of the temperature. The false air will then create a draugh of false air into the cylinder and cools down severely which will result in a major cylinder block damage.

For those running the German class 95, refer to the manual provided with the German class 95 package how to use this engine and the Riggenbach brake properly. Scenarios aew included for the Seeberg Line. The Seeberg Line is available as freeware DLC in the workshop.

The German Class 95 gots a Riggenbach counter-pressure brake to slow down when the train goes down a steep slope. This Class 95 here on the Ruhr-Sieg line created by BeeKay

2.07 – Boiler equipment

The boiler is the power supply for the engine to get running. A boiler is a transportable power plant that delivers the energy source to the steam engine putting the train in motion.

At the boiler and around the boiler there is a lot of additional hardware, but required to get the best result of the boilers main target. “The production of steam” The inside of the boiler has been viewed already and now the external hardware is now magnified.

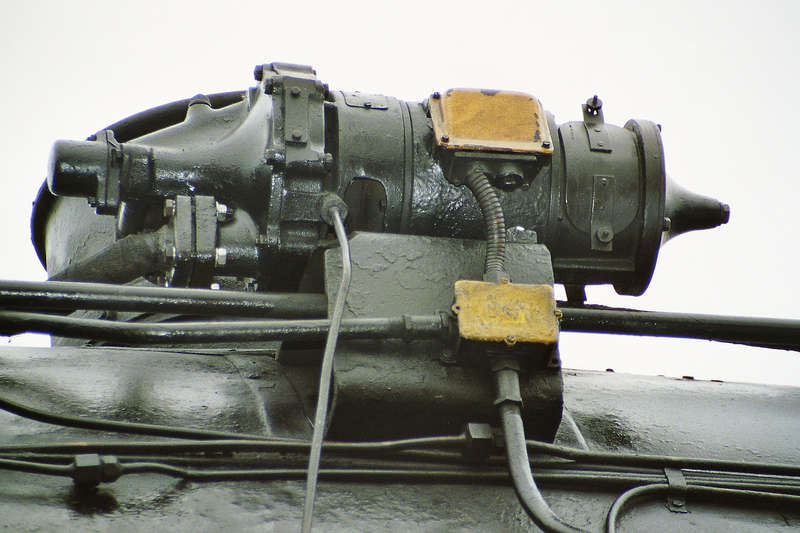

A steam driven turbo generator provides the electrical devices of electrical current. This current is needed to enlighten the cab, the head and rear lights, the AWS or other signal safety devices, the exterior light that lights the driving wheels and additional lights if necessary.

The turbo generates electrical power. The mass is directly connected with the boiler, that acts like the mass or negative pole at the engine.

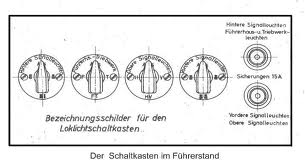

The wire is the plus (positive) pole that is fitted in a small tube that leads to the cab main switch board which is mostly mounted above the windows. The class 03 and 95 are equipped with a operational turbine driven generator and switchboard.

To operate the turbo and switch board, rotate very slowly the spindle valve clockwise that opens the steam flow to the turbo setting to rotator in motion. the rotating fan blades inside the rotator start to spin around picking up speed until about 5000 rpm producing mostly an 24V electrical current.

The switch board divides the currency to the desired devices and lights. On modern engines the electrical current is also in use for empowering the safety devices and to load battery pack in case of a malfunctioned turbo generator.

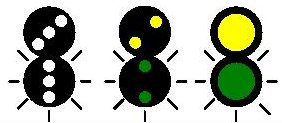

The screenshots of class 95 shows the use of the illumination of the driving wheels and the illumination of the gauges at the footplate.

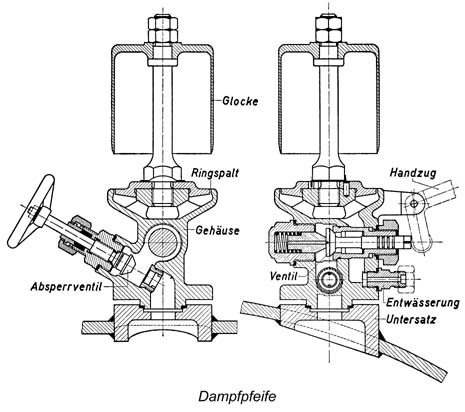

During the run the whistle is a hard and loud phonetic signal that can heard far away of.

The frequency in Hz of a whistle blow sound is widely audible and it will trigger the attention from almost everybody in the area close to the railroad. The right frequency is the source for the length in distance the sound carries away. This whistle is the common sound for approaching danger.

Secondly the whistle is to communicate between a double headed train. The first engine gives a certain whistle signal and the second engine respond to this whistle blow to confirm the signal from the first engine. Every country does have their own rules accordingly double head driving signals.

In TS2015 the [ “Spacebar” ] is in use to blow the whistle.

Some advanced engines uses the [ B ] or [ N ] for a short blow and the [ “Spacebar” ]

for a long blow.

The valve has to be open prior to the proper working of the whistle and needs to be closed when the engine is depressurized.

This whistle is used because of high whistle sound and often in use on local services on short distances and small engines. This type of whistle is mostly manufactured out of brass and copper. The polishing shinning effect the locomotive crew created was always known by everybody no matter which country or area the locomotive was running. The brass whistle was a famous point of recognition.

A bell gives the surrounding pedestrians a warning signal. This signal often in use on passing an unprotected level crossing which are regularly present on local lines and branch lines. All engines running on such a lines are required to have a warning bell. The driver operates the bell on approaching an unprotected level crossing.

The bell (if applicable) is in TS2015 operational by pressing the [ B ]

When in the 50’s the Flying Scotsman visited the USA the engine became a restricted bell and top light as well. After that visit the Flying Scotsman went back home and the bell came with the engine as a memorable gift to the BR.

Calcium sediment forms when water is boiled. After a while the calcium (limestone) will sink down to the bottom of the boiler ot on top of the crown plate. The sediment does not evaporate with the water into steam but remains behind in the boiler. During stationary periods, prior to a run or after a service when back on the shed, depot or workshop. A blow down is needed to release the sediment out of the boiler.

A special engineered valve by Ing. Gestra will release the sediment when operated.

The operation lever is installed at the footplate next to the fireman’s seat in German engines. Other engines does have other systems to release the sediment. The operational sequence.

- Inject water until 85-90% boiler content is reached.

- Unlock the lever wing screw

- Move the lever and hold for 10-30 seconds

- Set back the lever and screw the winged screw tithe to the screw holder that locks the lever.

- Inject water until the normal water level is reached.

If necessary repeat the sequence for a second time when the blow off could not be conducted in 30 minutes.

During the run use the Gestra valve about every 20-30 minutes when possible. This could be on departing the station (max. about 10 seconds), passing a bridge. in natural environment like wood areas, country sides, shunt yards when possible.

2.08 – Draining the cylinders

Steam will convert back into water when steam is cooled down. Steam on its own is invisible, but the condensation of steam is visible, This is seen and is commonly noticed as “smoke” or steam clouds. The steam particles will bound together (condensation) and becomes water again. Now Water is uncompressible and therefore dangerous in the cylinder if not drained of. The cylinder can explode when water is pressurized if not drained of.

Draining and warming the cylinders: Press [ C ] to open valve of the cylinder drain pipe.

Set the reverser at 10%. and open the regulator up to about 15%. This action drains the water out of the cylinder blocks by steam pressure and warms up the cylinder prior to your run. It is better to warm up the cylinder blocks when you are facing a non-stop long run. During the winter, at cold an rainy days, it is always required to pre-heat the cylinder blocks for about 5 minutes prior to departure, using the described method. Even more important when the temperatures sank down below zero. Always use this method to pre-heat the cylinders.

In some occasions you have to use a shred drained in oil and ignited with a match in order to de-ice the cylinder drain valves and pipes underneath the cylinder blocks.

Depending the type of loco and the scripting the creator/developer has implemented of the virtual loco have in your “shed” it will not always simulate the water draining unless the engines sets of. In reality the steam is blowing the water out of the drain pipes producing an amount of steam in front of the engine.

The water will be blown out by steam force.

Even though the cylinder blocks needs to warm up this will prevent the cylinders from malfunction. The difference in temperature inside and outside the cylinder can be that much the cylinders encounters the expanding friction of the steal which gives invisible fractures in the body of the cylinder. Even the lack of lubricating can harm the inner cylinder surface, the outcome of both issues will impact the run and cause server damage to the cylinder.

The cylinder could easily jam at once breaking the pistons off from the wheel taps.

When all the motional force is transmitted onto the piston when it comes off from the wheel tap, the weight and force of the train is released into the off coming piston. These pistons will become a fatal projectile. Striking and slicing everything that comes along the path of that piston. It easily cuts a “Peterbuild” 18-wheeler road truck in pieces.

When priming occurs. Water will get into the cylinder by steam force.

The springs however are tightly mounted and the spring are firmly pressing a valve at the small gap in the cylinder block.

This valve can stand a steam pressure easily, but will open the spring valve when water is pressing from out of the inside of the cylinder block by the tremendous water pressure and water is drained out under high pressure. When the water pressure continue to increase, the pressure will pushes on the surface of the cylinder lids, the spring holder, spring valve, the spring itself and the mechanical parts will still be ripped of by the power the water has at that moment. In the worst case the cylinder block will burst open causing a tremendous damage and could cause also a derailment during a run.

Opening the cylinder drain pipes on departure

2.09 – Topping up the supplies

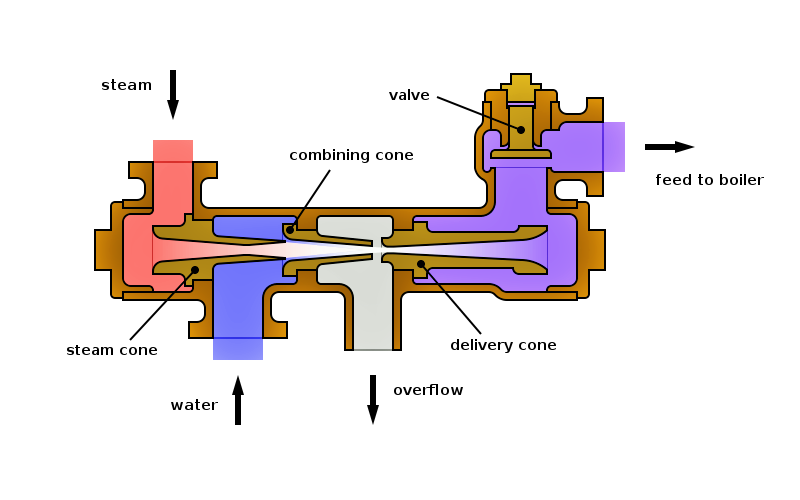

One of the basic important requirement to create steam is water, the most important substance needed at a steam engine. Now to inject water into the boiler you need to know how the injector works.

It is quite simple. Add steam to water through a narrow funnel or conic shape gap, then it expands and pushes the water with power. The gap is not bigger then a finger tip creating a tremendous force that overruns the steam pressure resulting the filling up of the water level. Based on this principle the boiler is feed by hot water.

Press [ L ] and hold to open the water flow to the Live injector until the valve is completely opened.

Press [ O ] to feed the injector with fresh steam.

Shut the injector down in opposite sequence.

Press [ O ] to close down the steam feed.

Press [ Shift ] – [ L ] and hold to close the water feed.

The exhaust injector is not working properly when the loco is not running,

because there is no exhaust steam.

To use the exhaust injector:

Press [ K ] and hold to open the water feed to the exhaust injector until the valve is completely opened.

Press [ I ] to open the exhaust steam feed.

Shut down is also in the opposite sequence:

Press [ I ] to close the exhaust steam feed.

Press Shift – [ K ] and hold to close the water feed and wait until the valve is completely closed.

Do not leave the water valves open. The water will flow through the injectors drain pipes on the track(side) and at a certain point by surprise you will encounter an empty tender while you had topped up

Always open up the water first, then steam. This prohibits the injector to get overheated.

An overheated injector will malfunction. In practice you should cool down the injector when

malfunction occurred. Take a bucket of water and throw the water over the malfunctioned injector. Do not do that too often, because a sudden cool down will crumble the injector as well.

Keep the water between 70 – 80% during a regular run.

In practice you have to be aware of the False Air flow Back which occurs when other values on the reverser remains present instead of the 30% and 70% positions. This is will cause “False Air” which will “suck” through the chimney into the cylinder and might damage the cylinders because of the sudden temperature drop.

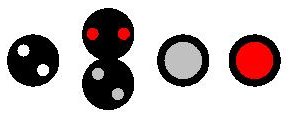

The working of the injector is seen here in this sketch;

Steam feed (red colored) can be applied by pressing the [ O ] (Live/fresh steam)

Water feed is bleu and applicable by pressing the [ L ] (Live/fresh steam injector)

The white area is the water overflow.

Water is drained off when the balance between fresh water and fresh steam is incorrect.

When the water feed and the steam feed are in the right balance, the water will flow through the purple pipe into the boiler.

However the proper working of the injector depends on the balance between the temperature and the amount of pressure of fresh steam.

In order to get a better understanding, watch the next short educational film about the working of the injector.

During and after injection keep an eye on the water glass and if the water level does not meet the desired level. Stop injecting after 2-3 minutes to cool the injector, wait a little while and start over again injecting. if necessary use both injectors at the same time. Do not inject water for a long period of time.

The water pump is a pump that excists out of three main parts. The steam cylinder, the water cylinder and the lubricator. The steam cylinder drives the water cylinder by fresh steam power. The water cylinder presses the water by force through the water feed pipe into the boiler. These water pumps are often in use on German engines.

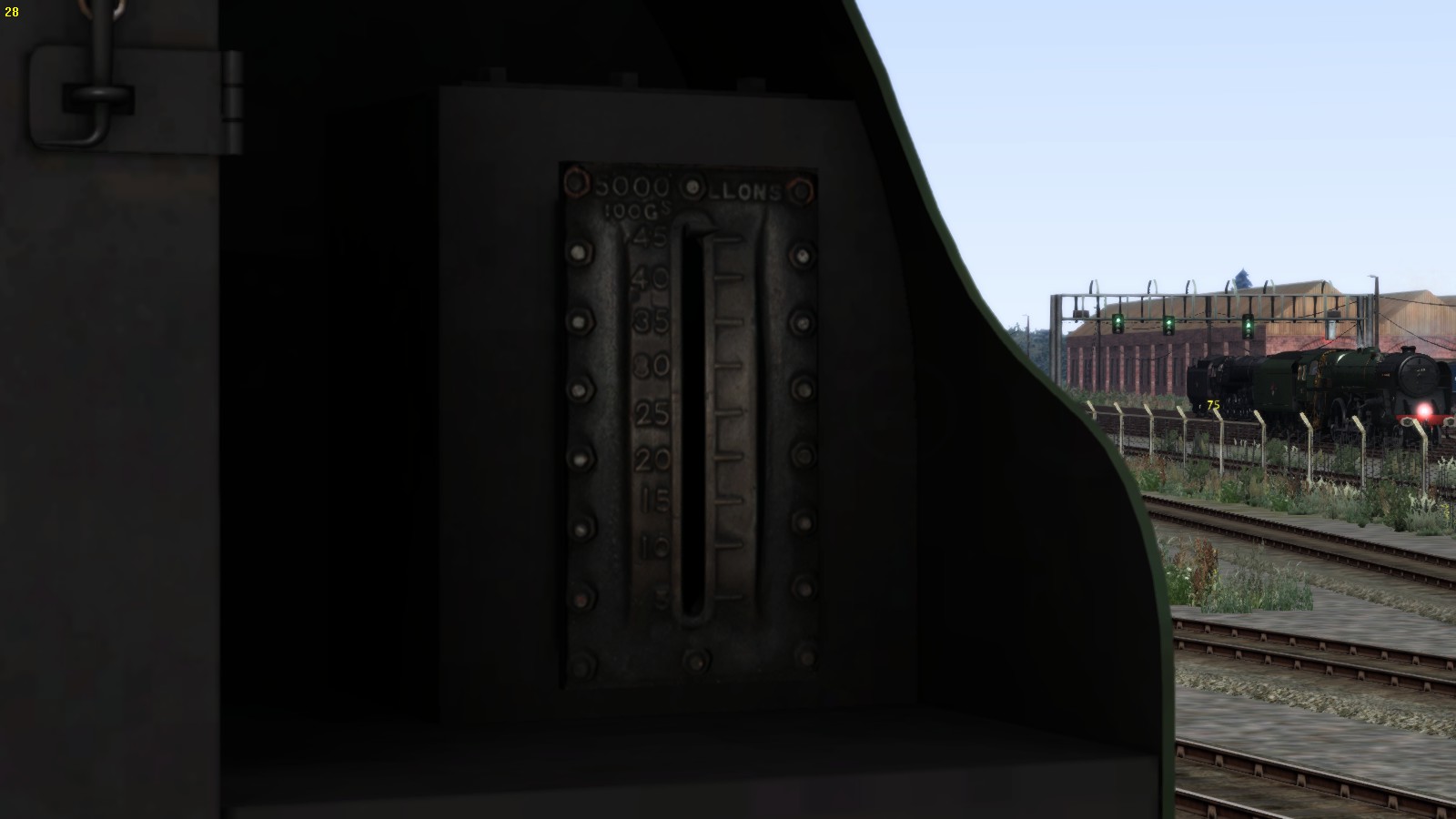

Press [ T ] to fill the tender.

Press [ T ] to fill the coal in the tender.

In order to use the hose, at some engines turn on the sprinkler system of the ash pan or smoke box prior to the use of that hose, otherwise the water will not flow through the hose. This is not simulated.

The sprinkler in the smoke box is aimed to prevent the metal to get overheated en needs to be cool down to avoid damage on the bottom of the smoke box. An overheated smoke box can cause open gaps and will result in a false air inlet decreasing the low pressure as result of effecting the fire in a negative way.

The same sprinkler system is in use in the ash pan aiming the same reason as for the smoke box.

This sprinkler system is often in use on German engines, but in most cases static in TS2015.

When the water is topped up. Chemicals will be added. These chemicals will prevent foaming of water and will decrease the amount of calcium preventing the forming of lime scale which will stuck on the pipes and tubes causing a decrease of heat exchange into the water. If not treated well the pipes and tubes can be damaged and steam will have access directly into the pipes and tubes which will end up at least in an uncontrolled blow back giving the same effects as a molten led fuse. At depots and workshops the water in the water tower will already contain these chemicals.

Now in the post steam era at many museum lines and preserved working engines, this chemicals are present as powder or liquid. Mostly stores in the support coach for materials, supplies, equipment and employee facilities.

Sand

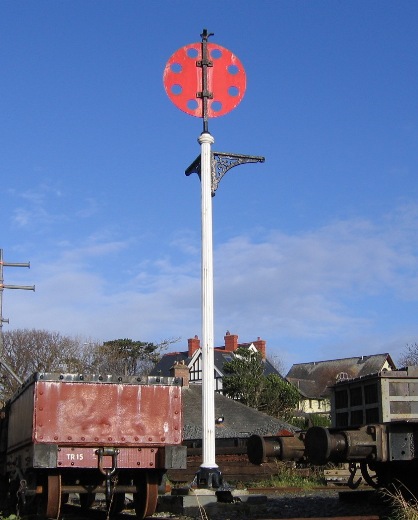

Sand is needed to increase the adhesive grip on the rail surface. The use of sand is also used to boost up the brake power in emergency cases. Sand is topped up on top of the boiler in a sand dome. The heat radiation of the boiler will dry the sand keeping out all moisture when present. Moisturized sand (mud) can block the down flow of sand through sand pipes. From the sand store, the sand is transported by air pressure through a pipe into the sand dome. To operate the sander press [ X ].

Some engines are enhanced with a sand loader system. To operate the sand loader drive the loco underneath the sand loader open the dome lid using [ Z ] and press [ T ] to load. This system is included at the Romantic Railroad Class 03 and Class 95 add-on’s from BeeKay / Just Trains.

When the sand, water and coal is topped up the engine is ready for departure. Do not forget to close the dome lid using [ Z ] when driving the class 95 or class 03.

2.11 – Departing, acceleration and stoking

211 – Departing, acceleration and stoking

On departing, open the cylinder drain pipes as mentioned in Chapter 6.

Open the regulator up to 75%.

Set the reverser at 70% according the direction you need to go and release your brakes

by pressing [ ; ]. Decrease the blower rate using [ Shift ] – [ N ]

Do not inject water on departure !

You need your steam (chest) pressure right now in order to accelerate and gain speed.

Do not forget to release the hand brake as well when applied !

Press [ / ] to release the hand brake if applied.

Decrease the reverser rate in balance of picking up speed and check you main pressure gauge.

Increase the blower.

When driving at about 10 Mph / 15 Kmh.

Close the cylinder drain pipes by pressing [ C ].

Reduce the regulator until about 60%, this is the most efficient position for a regular engine.

When running a tender engine, 30-35% will do fine.

Decrease the reverser accordingly:

Although you have to “feel” then you know when to reduce the reverser.

Check out the speedometer. When the meter stuck at a certain speed.

Reduce the reverser and the engine picks up speed again.

Here you discover the working expansion of steam in the cylinders.

Engines has a lock-up lever connected to a nudge which locks up the reverser.

Mostly press [ E ] to lock / unlock the locker if applicable and/or working.

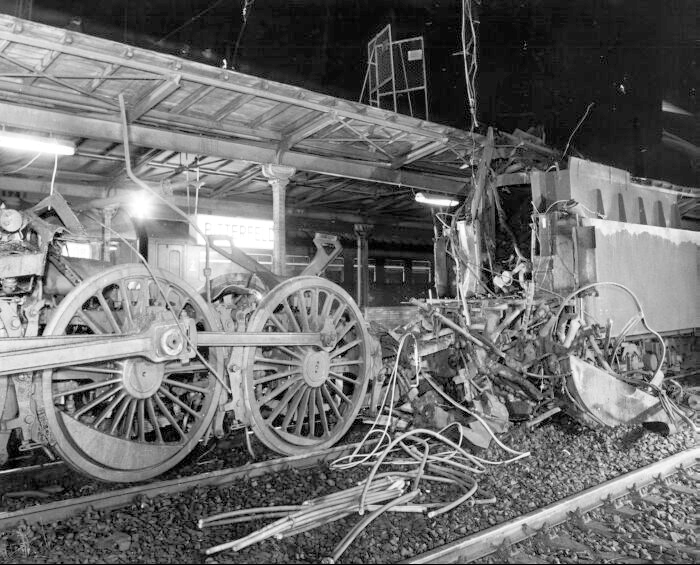

The use of the lock prevents the pistons to “swing” on their own resetting the reverser in opposite direction. In history some major accidents has been taken place due to the lack of locking the reverser. The forces on the pistons will have “feedback” in the reverser causes the bars and the pistons of the lever to adjust the position of the reverser. In the case of the disaster the pistons has moved the reverser in opposite direction causing the engine to run backwards causing a server disaster with many casualties.

On slippery rail/track use sand by pressing [ X ] and hold the sand for a while.

When the train slips (skimming), cut off the regulator and slightly open up again until the train picks up traction. Do not use sand when passing point and slips causing the moving parts to stuck by the amount of sand.

You will need sand on climbing slopes, heavy trains avoiding slipping and loose of traction

Reduce the blower rate in balance with the use of the exhaust, regulator and reverser.

Stoke the engine during acceleration and keep the fire between 75 – 80% !

On small tank engines like the J94 of 3F keep the fire between 60 – 70 % !

Do not stoke when stationary at public stations and platforms unless it is really necessary.

You will pay the laundry for the passengers near the engine.

The tiny coal dust and particles unable to be catched by the spark arrestor will exit the chimney and settling into the water condense, the coal particles will come down with the condensed water as fine rain creating tiny black spots and dots on the clothes of the surrounded pedestrians.

During stoking, the temperature in the centre of the fire will increase during acceleration and run, the temperature then will last up to 1500 degrees Celsius which is even hotter than lava.

The colour of the fire is then bright white and hard to look at. The arc mounted at the back of the fire box will create a “tornado” like airflow mixing up all hot gases prior to their motion through the pipes and tubes.

Watch the colour of the smoke coming out of the chimney. If the colour is light grey almost white, then start shovel. You need all your steam power to accelerate and hauling your train.

The exhaust will act like a blower as well. Now the blower will act only as an adjustable blower.

The working of the blower has been taken over by the natural exhaust of the engine.

The exhaust works when fresh steam feed is decreased. The exhaust is the expansion of the steam at the moment the reverser rate is decreased. Due to that expansion the engine get the full result from the power of steam. Though the reverser and regulator has been cut off, the engine still picks up speed. This is the final result of expansion. To keep the speed you have to decrease the reverser even more. The motional pistons now “translate” this power onto the wheels into a circular movement causing the train to drive.

Do not inject water and stoking simultaneously in order to prevent malfunctions of the injector and the possibility of a blow back.

Unless extremely nessesary, use both to top up when the water level has dropped that much facing a dry crown plate of the fire box.

The fuse plus was covered up with calcium. The low water level was still covering the crown plate. The stopping train resulted that the water moved to the front away from the crown plate. Because the fuse plug was covered up with calcium, the fuse plug was malfunctioning.

The boiler ripped open and depressurisation causes the water to turn into steam immediately.

When the pressure is at 220 PSI / 16 Bar, the boiling point of the water is then at about 200 degrees Celsius.

Because the pressure dropped at once to normal conditions (about 20 PSI / 1 Bar) the boiling point of that water in that boiler is dropped with it to the common 100 degrees C. and turned into steam at once creating the major explosion.

These are just some examples of boiler explosion. There has been more explosions in the past, mostly because of human failures or mechanical causes. In most cases driver and fireman lost their lives.

2.12 – Stoking using heavy oil

212 Stoking using heavy oil

Engineers were continuously seeking for method to overcome economical issues trying to find the best advantages and profitable ways to create steam effectively. Even after the war the request to get the best for the lowest price resulted in overhauling engines to re-establish the transportation and infra structures and economical contribution in the shortest period of time.

To achieve this target engineers start to reconstruct the steam boilers in high performance boilers that could last longer producing more steam on an average steam locomotive. Coal became ineffective and was expensive. The solution was to install special burners into the firebox to burn heavy oil. Heavy oil was cheaper than coal.

The profit rate of heavy oil was even higher than the profit rate of coal. Firing the engine became much easier and the use of heavy oil made it possible to switch off the fire when the engine is stationary. New steal boilers were welded instead of riveting and lesser steam domes were present. The fireman has less work to do and the physical stress due to the duration of shovelling was eliminated.

Engines that remains on coal firing were scrapped 5 to 6 years earlier prior to the scrapping of oil fired engines.

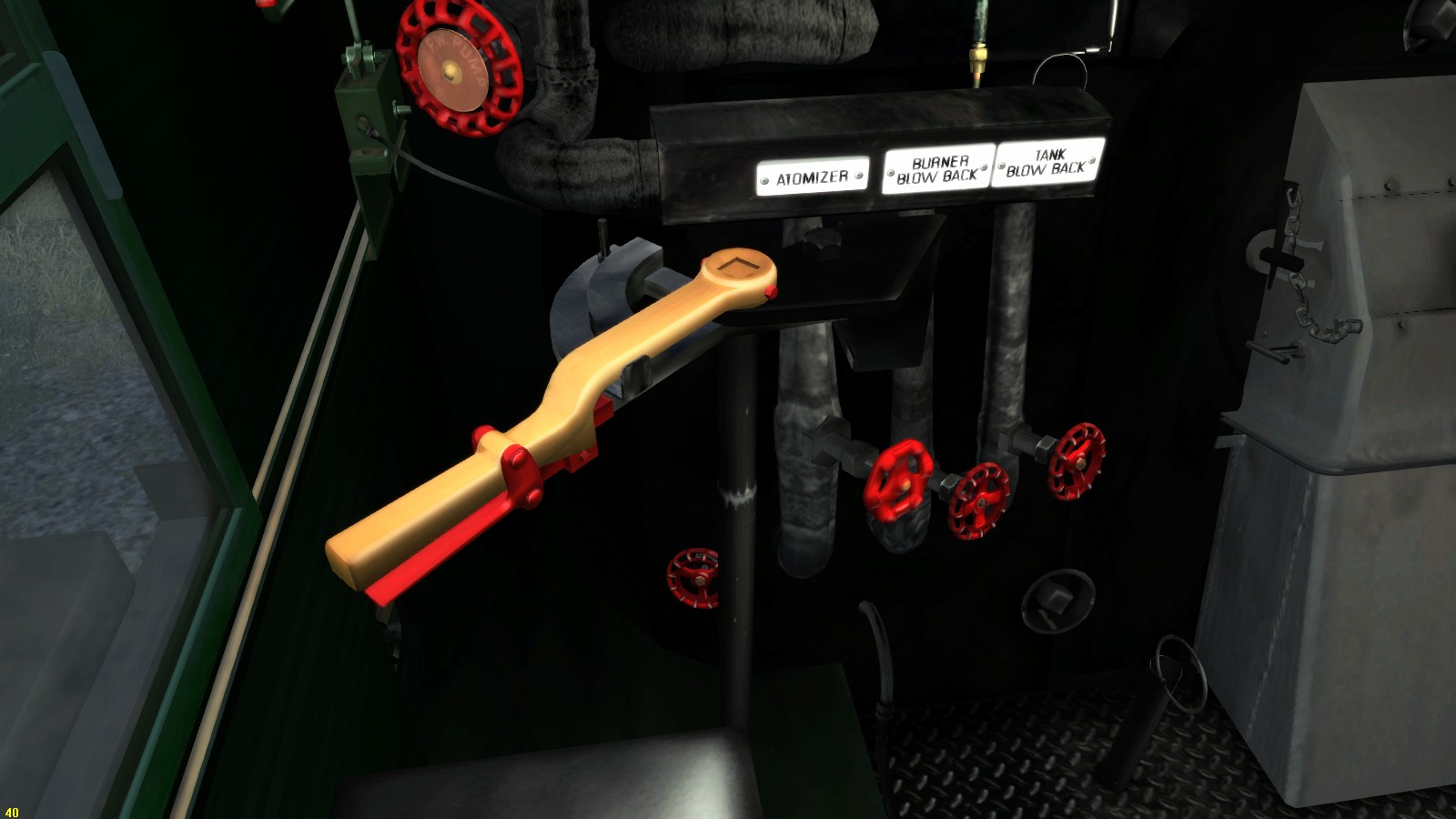

The oil firing in TS2015 works the same as coal firing. Actually the meaning is different

- Open the oil valve press [ F ]

- Closing th oil valve press [ Shift ] – [ F ]

- Increase oil amount press [ R ]

- Decrease oil amount press [ Shift] – [ R ]

To fire up a oil fired steam locomotive you need to have pre heated oil the viscosity of heavy oil is like thick syrup and needs to be warmed up to get the oil liquid to flow. Now when a pre heat system is not present the oil needs to warm up by an extended heat source. This is usually a coal fired engine. The steam produced by the coal fired engines will heat up the oil in the tender up to a 110 degrees C.

The oil now can be pumped with the use of the external steam source through the atomizers that are installed just above the fire grate. This fire grate does not have the coal grates but does have a few bars between left and right to let the air through.

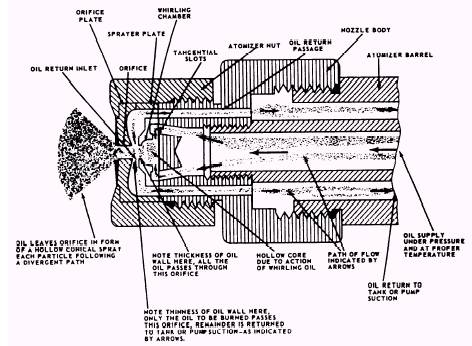

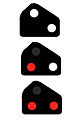

An atomizer sprays the oil into the fire box using two nozzles. The nozzles are mentioned in the diagram and shows the working of the oil atomizer.

The firedoors does have a small gap for two reasons.

1 – To check the fire.

2 – To insert sand.

Sand is used to insert into the fire box to clean out the tubes and pipes. The sand acts like a grinder that “grinds” tubes and pipes surfaces from adhering oil and/or tar. The sand forms small chunks of tar that is blowing out through the chimney or falling down in the smoke box. These oil components are non-combustible and if not cleaned these oil/tar will result in the same effect as lime scale in the boiler itself.

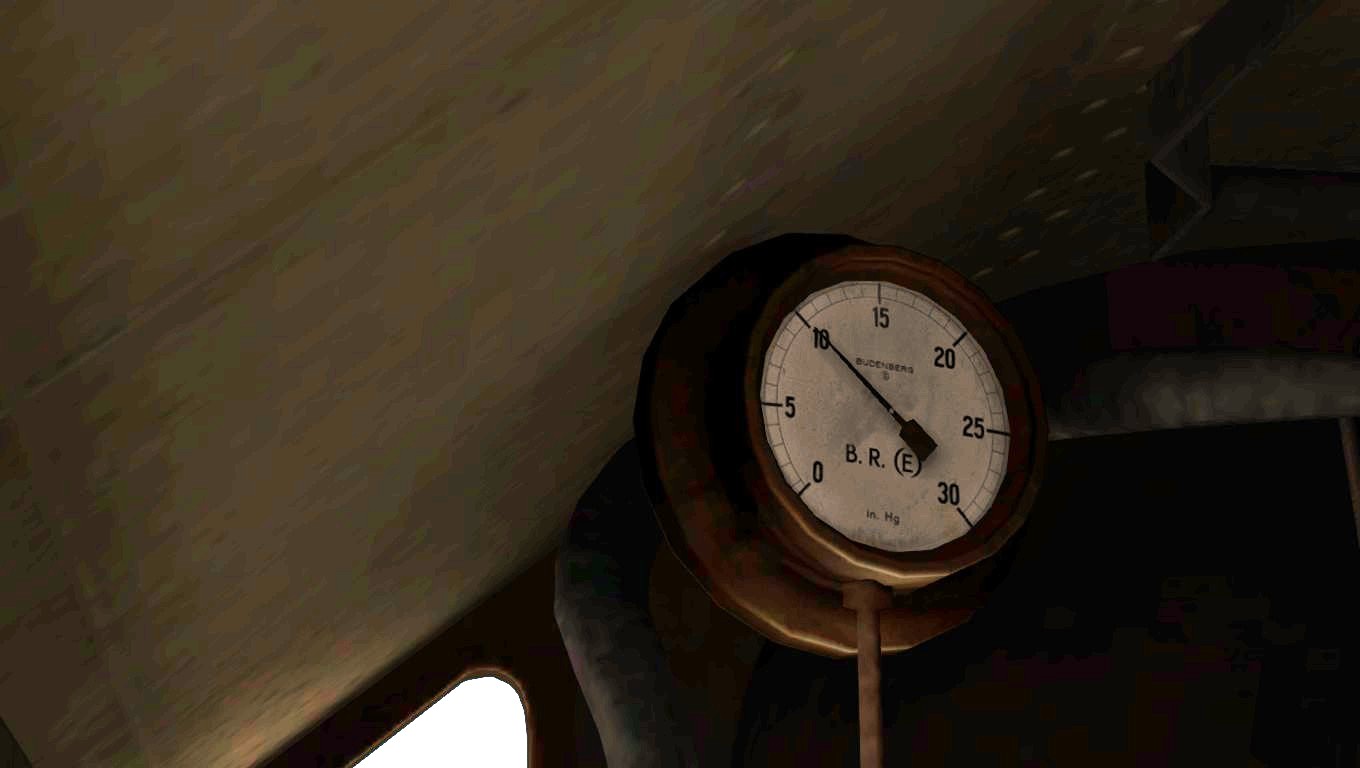

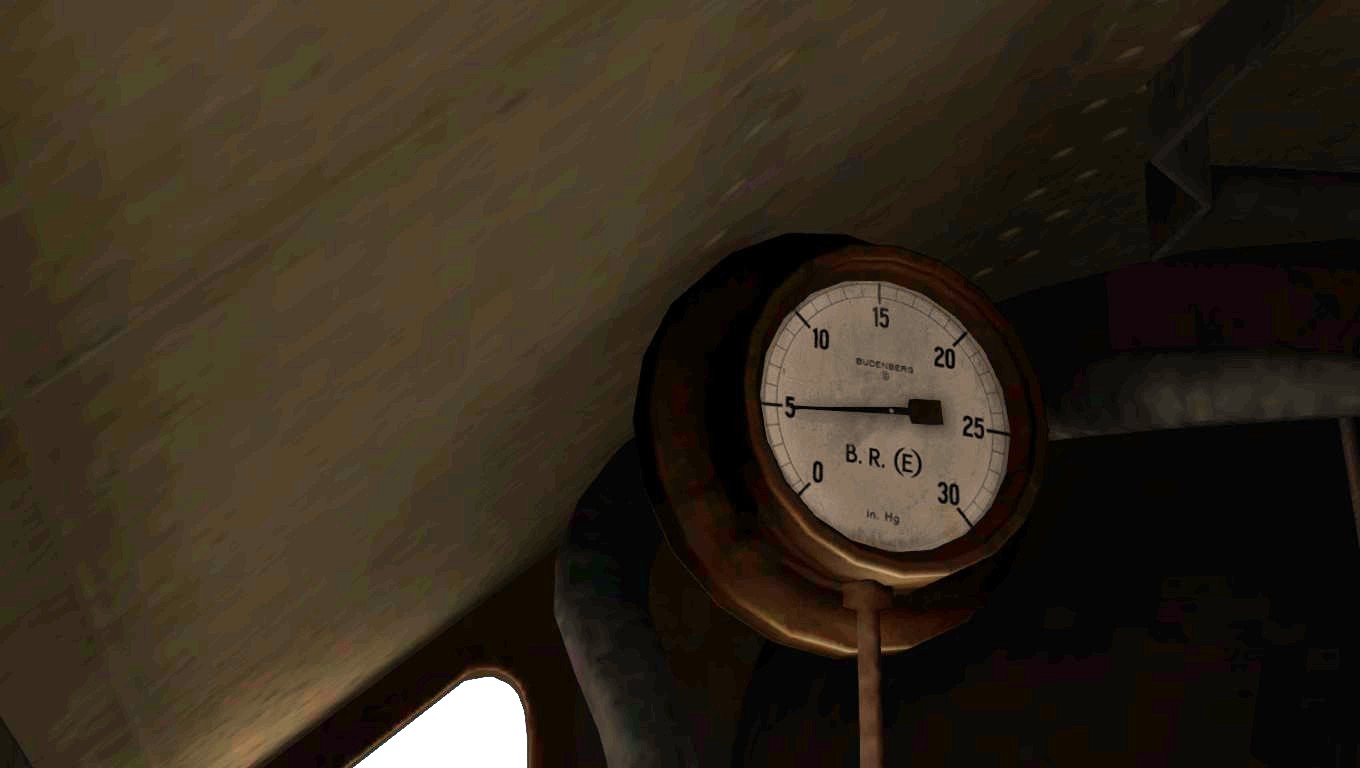

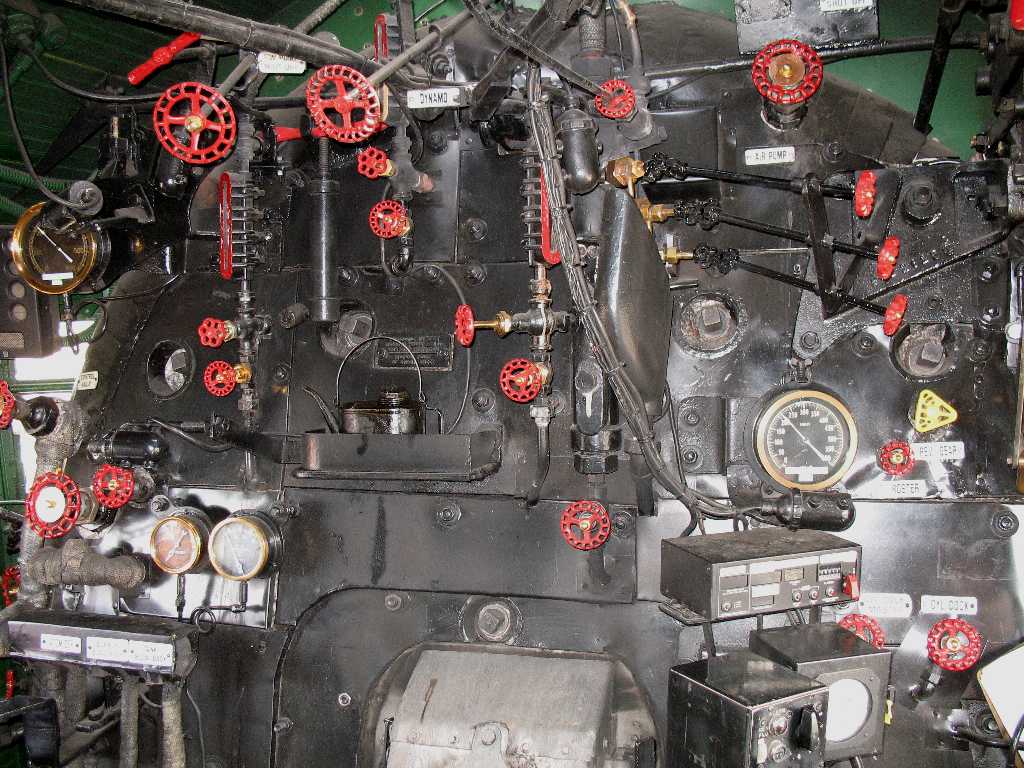

The two nozzles / atomizers are separately adjustable. Every nozzle works fine when the oil pressure is balanced at about 2 Atm. per nozzle. The high temperature ignites the oil directly creating the super hot gasses that is lead into the tubes and pipes generating steam. The pressure that the nozzles contains are separately readable by gauges that are installed in front of the fireman.

Close to the fireman a bucked of sand with a small shovel that is used for insert sand through the gap in the fire box door. The fire box door is only opened for maintenance and is locked up with the lockers that are present at the side of the fire door.

When heavy oil is pushed through the nozzles in the fire box a second nozzle blows steam under high pressure against the oil stream from underneath that atomize the oil which ignites immediately. the steam injection and the oil flow can be operated separately and can be fine tuned due to a series of valves which is installed left from the fire door.

It was even possible to top up the oil supply directly from the wagon itself if a bunker storage was not present.

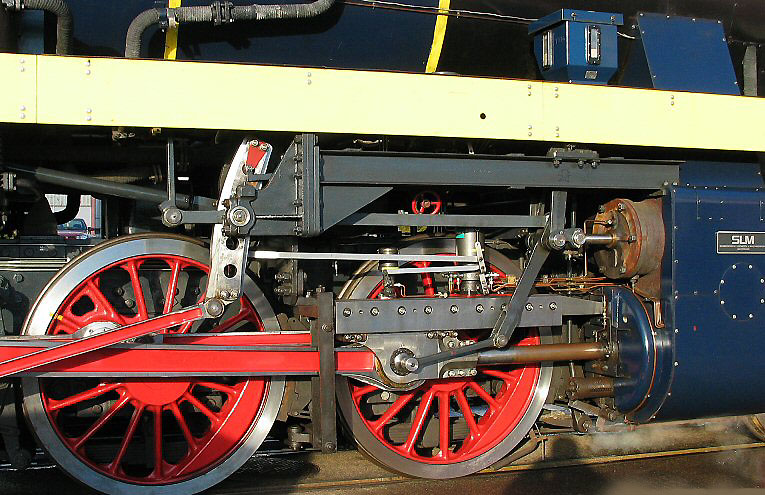

The 52 8055 is recreated by the Swiss compagny DLM at Winterthur. The engine is fired by

light oil and one-man-operational. The sliders at the crosshead contains roller bearers and approved for 62 Mph / 100 km/h.

2.13 – During the run

Now you are running on the track, you now have to deal with a lot of situations.

Keep also monitoring the water level regularly.

Do not inject water until the run becomes stable.

This is also the reason to top the water up when the boiler is in state of “rest”.

Press [ K ] to open the water feed of the exhaust injector. (Press Shift – [ K ] to close)

Press [ I ] to open the exhaust steam feed.

Press [ I ] once again to close the steam feed when ready

Do not use two injectors at the same time as mentioned before. This will cause a steam pressure drop unless it is necessary due to some tremendous drop of water level in the boiler.

During the run, use the Exhaust injector. When stopped, use the live injector.

Prevent the drop of water level less than 70%.

Less water will result in unnecessary usage of steam.

The evaporation surface will increase on the decreasing of the water level which causes more stoking in order to keep up the water level.

You need to inject more causing steam usage which is resulting in a increasing rate of coal consuming. You then need more coal to keep up the pressure.

This is why you have to keep up your fire and water level

Easy to remeber: Keep it up above 70%

An exception is the Challenger and Big Boy. Keep the water level above 96%. The amount of water use is tremendous. To keep the water evaporation surface as small as possible, it is necessary to keep the water level as high as possible.

- Stoke 8-10 shovels at about 10 kg of coal per shovel you throw.

- Check pressure

- Inject water (Exhaust steam)

- additional Inject water (Live steam) only at low water level.

- Check steam chest pressure when driving.

- Check brake pressures.

- Adjust the use of the small ejector

- Check water level

Before you set off. Test the injector use by using the HUD display. After checking and taking notice the motion and position of the valves, you now can rely on the manual use or by mouse. Check the water valves if they are closed well after closing the steam valves of the injectors. Pressing F5 after closing the steam valve shows the tender water level slowly decreasing. This means a valve is still open when the injectors are not running.

Another way of checking the water overflow is by hanging out the window and look down. Here you better go outside next the cabin using camview by pressing [ 2 ] and aim the view on the injectors. when water comes out, the water valve is open.

Make adjustments to the blower rate if necessary in addition of the exhaust.

Increase the blower rate in balance of the decrease rate of the regulator and/or reverser.

Check the colour of the smoke, when the smoke is light grey, it is time to shovel again. Stoke about 10 shovels at a time until the smoke is dark grey.

The use of steam and water depends on the use of additional equipment resulting in about 4 – 5 cubic meter of water extra over a distance of 125 miles / 200 km. In the winter even more because of the steam heating when you haul a passenger train. Then you can last up to 125 miles / 200 km.

You shovel about 1000 kg of coal at a distance of 35 miles / 50 km. Every 2 – 3 minutes depending the weight of the train, the type of landscape, the weather conditions and the state of the engine could also results to shovel every 1 – 2 minutes shovelling the coal on the fire grate.

With a rate of 10 shovels in the frequency of 1 – 2 minutes, every shovel contains up to 15 kg. of coal depending the size of the shovel. After 125 miles / 200 km. 4 tons of coal are consumed by the engine in normal conditions. Also in the winter the amount of coal consuming increases and is in balance with the use of water. Depending your stoking experience you are able to stoke and safe coal consuming.

The best way to stoke is to maintain the Horse Shoe fire. Less amount coal in the front and middle of the fire grate and a high amount of coal at the left and right side of the fire box and grate and high amount of coal just underneath the fire door opening.

The coal will scatter down to the front by the humping and bumping motions of the engine.

Now the fireman have to stoke at the front edges of the fire box, but still covering the fire grate to prevent a cold air flow in the fire. Looking top down on the fire grate will recover a “Horse Shoe” shape at the coal bed.

When approaching a tunnel, be sure your blower is on and the fire door closed. Open the fire door will result in a blow back. During a passing through a tunnel, your fire should be in an state of “Rest” with no fresh coal on the fire bed. Keep the blower running during the tunnel passing. Use if necessary the live injector to feed the boiler. Also to prevent the waste of pressure when present in the boiler When exiting the tunnel start to stoke immediately.

This shows the direct need of cylinder drain pipes in case of doubt, just open the water drain to drain off the water.

Better you lose pressure instead of loosing water.

Loosing water will cause a boiler explosion causing casualties an injuries.

If you are doubting. Stop that train! no matter what!

Then: In practice. Open the ash pan and rock the fire away from the grate. Safety first at all times. On top of the fire box there is a safety plug of lead. When the water level drops below the top surface of the fire box the plug will melt and steam fills the firebox with high pressure. Causing the fire to extinguish. When this safety plug should not work a boiler explosion will occur.

2.14 – Stopping a train, a skilled performance

“It is not how to drive a train, but how to stop a train.”