Overview

Cause the tablet just isnt enough help

Brief

Created to help those in need, Pocket Reference “In Space”.

Each section contains a “Last successfully tested” and a version number. If a new release has been published and this does not get updated, it is possible that the behavior has changed and we’ve either not yet updated the guide or have moved on to other games.

The game is still Early Access when we’re publishing the guide and things are still subject to change.

Nonetheless, we’re the curious type (as this peaking in windows shows) and can’t help ourselves but to tinker with the systems Stationeers presents and figure out how things work.

Stationeers Website[stationeers.com]

Stationeers Discord Server[discord.gg]

https://www.reddit.com/r/Stationeers/

Stationeers Community Wiki[stationeers-wiki.com]

Stationeers Change Log Tool by Melair[stationeers.melaircraft.net]

Solar Panel Basic information

This section is intended to provide baseline Solar Panel information.

Panel(v) = Verticle arc of panel

Panel(h) = Horizontal arc of panel

Panel(w) = Current W output of panel

Panel(M) = Maximum potential W output of panel (500W as of 0.1.1501.7112)

Panel(e) = Panel efficiency based on tangential angle. When the angle between the sun and the panel face is perpendicular, the efficiency is 100%, when the angle between the sun and the panel is parallel (or if the panel is > 90 degrees facing away from the sun) then the efficiency is zero.

Panel(o) = Panel occlusion represented as a 100%-0% value based on inverse occlusion. (i.e., when not occluded, Panel(o)=100% and will decrease as occlusion increases until Panel(o)=0% when the panels are fully occluded.)

Sensor(v) = Verticle return from sensor based on facing at a given time of day. Sensors facing different directions give different values at the same time of day (i.e., A zenith (upwards) sensor will give a different value from an East sensor at noon.)

Solar(e) = Solar efficiency based on distance from solar object (i.e., the Sun).

After 0.1.1501.7112, Stationeers introduced a Solar zenith angle modifier to custom worlds (Mars & Europa). For the Moon, the Solar zenith angle is 0 degrees (East to West, with the Sun being directly overhead at 90 from E-W and 90 degrees from N-S at noon.)

For Mars and Europa, when the Sun is at 90 degrees E-W, it is at an adjusted zenith angle N-S.

Sensor(v) will return 0 at noon on the Moon.

Sensor(v) will return 8 at noon on Mars.

Sensor(v) will return 32 at noon on Europa.

0.1.1501.7112 also introduced solar efficiency adjustment. Moon provides 100% solar, Europa (near Jupiter) provides only 42% Solar(e).

When calculating impact on solar panels, Panel(w) = Panel(M) * Solar(e) * Panel(e) * Panel(o).

On the Moon, with a 100% Solar(e) and panels aligned perpendicular to the sun, and not occluded Panel(w) = 500 * 100% * 100% * 100%, aka Panel(M) = 500W.

Whereas on Europa, with a 42% Solar(e) and panels aligned perfectly, and not occluded, Panel(w) = 500 * 42% * 100% * 100%, aka Panel(M) = 210W.

No effort is made to factor Panel(e) or Panel(o) in this guide due to the environmental factors required to calculate. They are mentioned solely to assist Stationeers in understanding how the environment can further impact solar power output, even when logical factors like proper panel alignment are removed from the equation.

Even when using the most efficient formula for Panel(h) and Panel(v) alignment, Panel(w) can and will be further degraded by solar efficiency and occlusion. This information must be considered when settling on a type of power generation for a base to maximize ROI during the start of a new Survival map.

Solar panels follow the sun (Vertical, Basic)

Goal: Automatically adjust Solar Panel Vertical angle automatically throughout the day to maximize power generation, and to align the panels towards morning.

Required items: Solar Panel Kits, Glass, Coil or Heavy Coil, Memory x3, Sensor, IO x2, Processor x3

You can run the Solar Panel variant 1 to separate network and power ports to simplify wiring. However, batch writers treat variant 1 as different types of solar panels from variant 2– which means you need multiple batch writers (currently) if you use different panel types.

This setup connects the Solar Power to an APC, and then the APC is connected to all the logic except for the batch writer output which connects back to the power generation network to control the solar panels.

Brief: Align panel vertical angle to maximize power generation (496-500 kW per panel) automatically throughout the day.

Detail: Daylight Sensor updates every ticket (0.5 second) with the current solar angle. This triggers logic update events. 15 is deducted from the solar angle to maximize alignment of the panels with the sun. Divided by 1.5 to adjust the 180 degrees of the horizon to the 100 degree vertical range of the solar panels. We then take the current adjusted solar angle, or 100, whichever is less. (If the panel verticle is set > 100, it flips to 0 and then aligns towards 100 only to flip back to 0. This is a range overflow bug in the current version.)

Last version confirmed success: v0.1.1420.6788

Solar Panels follow the sun (Vertical, Advanced)

Goal: Automatically adjust Solar Panel Vertical angle automatically throughout the day to maximize power generation, and to align the panels towards morning.

Required items: Solar Panel Kits, Glass, Coil or Heavy Coil, Memory x3, Sensor, IO x2, Processor x3

Additional chips required for Horizontal solution: LogicI/O x1, LogicMemory x2, LogicProccessor x2

Optional items for End of Day Reset: Memory x1, IO x1, Processor x4

Yellow – The Verticle Solar Panel chip solution.

Green – The Horizontal Solar Panel chip solution. (See next section)

Purple – The advanced logic that redirects the solar panels to point towards sunrise a handful of ticks before the solar panels stop producing enough energy to power the logic circuits. (The Memory Chip in the upper right is set for 167, the point at which 10 solar panels will fail to produce enough power to keep the logic solution powered– but if your power demands cause the power to fail earlier you can increase the setting up to 180 which is the start of sundown. If your power demands cause power outage before that, you’ll have to craft your own solution or add more panels.)

WARNING: There is an edge case in this logic where if the power draw on the supply network exceeds supply prior to SolarAngle 167 (during the sunset cycle) then the logic system will brown out and fail to send the reset signal towards sunrise.

I (Mazian) plan to come back to this section and improve it– but I want to finish the rest of the guide so I’m leaving this as is for now. The real challenge is that batteries can consume 100% of the power and therefore the only solution is to put the logic system power on the far side of a battery to ensure adequate power. This can either be a Kit (Battery) or an APC with a battery installed. The exact layout will be revisited at a later time.

Brief: Align panel vertical angle to maximize power generation (490-498 kW per panel) automatically throughout the day.

Detail: Daylight Sensor updates every ticket (0.5 second) with the current solar angle. This triggers logic update events. 15 is deducted from the solar angle to maximize alignment of the panels with the sun. Divided by 1.5 to adjust the 180 degrees of the horizon to the 100 degree vertical range of the solar panels. We then take the current adjusted solar angle, or 100, whichever is less. (If the panel verticle is set > 100, it flips to 0 and then aligns towards 100 only to flip back to 0. This is a range overflow bug in the current version.)

See Youtube page for specific timestamp markers. It’s 4:30 long.

[link]UPDATE v0.1.1420.6788: THE Kilroy suggested changing the MEM_15 to MEM_14.5 to advance the solar angle to counter chip delay and get better power generation. Tested and confirmed it works. I’ll do updated screenshots at some future point.

Last version confirmed success: v0.1.1420.6788

Solar Panels follow the sun (Horizontal)

Goal: Cheeply set horizontal angle of new panels

Needs clean picture of chips, at least to show scale of project

Needed items: LogicI/O x2, LogicMemory x2, Kit Sensor , LogicProccessor x2

If already using a reader for vertical tracking you can get away with -1LogicI/O and -1Kit Sensor

- Sensor_SolarAngle:Daylight Sensor(Kit sensor). place facing the sunrise.

- Solar Panels: place all the bases of panels to be oriented the same.

- Read_SolarAngle:Reader, can use the same reader used for vertical tracking

- Sensor_SolarAngle:Daylight Sensor, can use the same sensor and reader used for vertical tracking

Brief: Read_SolarAngle updates all the time, and is already used if you have vertical control, use that constant update to constantly update horizontal angle.

Detail: Read_SolarAngle returns (0<->180), so converting that to vary a small decimal, and adding that to your desired angle. BW_Horz updates between (Mem_HorzAngle+(0<->0.036), always triggering an update to any panel including new panels.

Last version confirmed success: v0.1.1373.6615

My First Airlock

Goal: Quickly set up your first airlock

Airlock components:Airlock x2, Console x1, Circuitboard (Airlock Control) x1, Glass x1, Gas Sensor x1, Active Vent x1, Passive Vent x1, Data Disk (Not consumed)

Requirements: a connected airtight room(preferably capable of 101 kPa), Cable Coil, Pipe, Steel or Iron Frames, Steel or Iron Sheets,

Optional: Walls can replace Frames of the room(airlock chamber should remain frames though), Light or Flashing Light(used as indicator)

- Wire all electric and logic connections to the same power-data network as the console,

- Insert Circuitboard (Airlock Control) into the “unfinished” console, then finish console construction with glass sheet

- Insert Data Disk into the console‘s side slot and turn it on

- Select Exterior Airlock first (Selected Airlock door light will turn red, if the wrong door is lit, deselect and select other Airlock)Renaming the doors with the labeler during construction can avoid confusion

- Select remaining Airlock components:Gas Sensor, Active Vent, Passive Vent, (optional Light or Flashing Light)

- Remove Data Disk

- Active Vent inside the airlock chamber

- Passive Vent inside the airtight room

- Connect the two vents together with pipe, note that an obvious “pipe path” may be blocked by the airlock door’s open position.

Brief: Upon Entering, the Airlock Controler attempts to pressurize the chamber to 101 kPa before opening the Interior Airlock. On Exit, the Airlock depressurizes to 0 kPa before exiting.

Detail: The Airlock Controler Console makes all the Airlock Door buttons and the console itself change to read “Cycle Airlock”. It will manage whether the Active Vent pulls gas from the airlock(to open exterior door) or push gas into the airlock(to open interior door).

Moon vs Mars: Airlock Control functionality assumes Space/Moon conditions. Adjustments are required for Mars and Custom world conditions. e.g., on Mars, the Airlock will depressurize to 0 kPa on exit, then ingest Martian Atmosphere that will be mixed with the interior habitat atmosphere when re-entering. This would require filtration to purge pollutants. Alternative setups are possible but Circuitboard Airlock Control behavior is consistent.

Configuring & Operation:

[link]

NOTE: If the internal, external airlocks are reversed during configuration, the airlock will vent atmosphere to the exterior on exit and depressurize before allowing entry to the interior.

Last version confirmed success: v0.1.1373.6615

My First Room

Goal: Create a pressure sealed room and pressurize.

Required Items: Iron Frames or Steel Frames, Iron Sheets or Steel Sheets. Match Iron Frames and Iron Sheets or Steel Frames and Steel Sheets.

Variations: Kit (Wall) aka Steel Walls and Kit (Iron Wall), Glass, Steel Sheets or Iron Sheets.

Also required, an Airlock to permit entry and exit without loss of atmosphere.

WARNING: Frames are required for placement of some structures and Walls and windows can prevent placement of some components. When in doubt, use Frames, place all pipes, coil, and all mechanisms, then place walls and windows.

NOTE: When building hydroponics, optimal sunlight exposure requires that the windows be East-West. So any controls, vents, temperature control, airlock, etc. should be placed North-South. Always evaluate cardinal directions prior to orienting your airlock & windows.

Place Frames North/South and leave space for your future airlock.

Frames: Place frame(s), swap to holding the welder and sheets of matching material, turn on welder, weld two sheets to each frame to make them pressure safe.

Walls: Place walls, then apply sheets to make them pressure safe.

Windows: Using Walls, select the Window variant, place windows, then apply sheets, then apply glass.

Make sure that every frame is filled and every wall and window is completely filled.

Create Airlock (see previous section.)

Pressurize.

Frames: Effectively infinite pressure (Attached vents connected to pipes, windows, doors will all rupture before frames will. I have not tested upper internal pressure limit for a single cube volume steel frame space.

Walls: Composite (Steel) Walls are rated to 300 kPa, Iron Walls are rated to 100 kPa

Windows: Windows are rated to 200 kPa

Oxite or your o2 portable tank (spawns in every survival map) can both be used to pressurize an atmosphere that is breathable.

WARNING: Pure O2 is flammable at high temperature. If you use Oxite or the o2 portable tank to pressurize your room, be sure to add a cooling mechanism ASAP to prevent combustion.

See Filtration & Temperature control for more details

[link]Last version confirmed success: v0.1.1373.6615

Temperature Control (Wall Heater and Wall Cooler)

Goal: Maintain temperature of an atmosphere to a comfortable level for plants and animals(including humans)

Needed items: Logic Memory x2, Logic Proccessor x2, Logic I/O x3, Wall Cooler, Wall Heater, Gas Sensor, Radiator, Some Pipe, Active Vent(not consumed)

- Charge the radiator’s pipe to about 50-100 kPa,by placing an active vent(shown green) where the wall cooler goes, and drawing gas from the already pressurized room.

- when pipe is charged, replace active vent(shown green) with the wall cooler(shown orange)

- Radiator must be in the vacum of space or a very cold area

- Sensor_GasSensor:Gas Sensor(Kit sensor) must be inside.

Brief: If the temperature from Sensor_GasSensor reads out of the target range, wall heater or wall cooler will be activated.

Detail: since Sensor_GasSensor reads in K not C, your tablet will read around 20C not 295K, but you can observe the LogicReader to see the temp in K, or use a gas display console which will convert to display C. To increase cooling capacity increase the length of the wall cooler pipe and the number of radiators. To increase the heating capacity increase the number of wall heater but BEWARE each wall heater uses 1kw and small cable coil can only support 5kw total.

It is better to charge the radiator pipe with X-Coolant but that would require more infastructure and not needed for the purposes of this reference.

Last version confirmed success: v0.1.1373.6615

Temperature Control (Passive Radiation & Airflow)

Goal: Room cooling with volume pumps and logic only, no Wall Coolers or Radiators.

Needed items: Passive Vent x2, Volume Pump x2, Sensor x1, Logic IO x2, Memory x1, Processor x1, Pipe, Radiators

- Place Passive Vents facing into the room.

- Connect Passive Vents to Pipe

- Place a volume pump between each passive vent and radiator pipe network, one facing into the room and the other facing away from the room.

- Extend pipe network in a loop from “output pump” to “input pump”

- Attach Radiators to pipe

- Place and wire logic

- Configure logic & test (You can pre-charge the radiator pipe with 101 kPa manually to provide something for the radiator pipe network to cool, or you can wait for the system to kick on and automatically. It will eventually reach equilibrium.)

Brief: Push air through pipes with radiators when room is too warm, cooling the room.

Detail: When the room is too warm, the volume pumps are enabled pushing the room atmosphere into the radiated-pipes and the cool air is pushed into the room. This continues until temperature between room and pipes equalizes. When the temperature returns to an acceptable range, stop volume pumps. While stopped, air in radiated-pipes will chill, providing a strong chill factor when pumps are initially turned on. Solution scales well by adding more pipes and radiators to increase radiator-system volume and does not increase in electricity cost.

Because Volume Pumps are “% transfer” mechanisms, setting the Volume Pump to 100L for input and output will equalize pressure between the room and the radiator pipe network. There is no need to pre-charge or manage the pressure in the radiator pipe network. (Although you certainly can pre-charge by manually activating the volume pump to pull gas from the room into the radiator pipe network. This somewhat speeds up the process.)

Volume Pump: 0-200W each (400W total when active)

IO: 10W each (20W total)

Processor: 25W

Total: 45-445W

vs

Wall Cooler: 100-300W each (depending on whether or not it is active.)

Plus 45W for logic

Total: 145-345W

Anecdotally, the Wall Cooler has a fixed heat transfer rate. However, if a single cooler is unable to maintain temperature for your room, then multiple Wall Coolers will be required (With either a shared or separate radiator pipe network.) Adding Wall Coolers increases power demand in proportion to the number of Wall Coolers added.

Based on observation, the cooling potential of the Passive Airflow solution is defined by the volume of pipes in the radiator pipe network adjusted by the temperature of the radiator pipe network, and the cooling scales with the number of radiators. In practice, when the pumps kick on, the cooling effect is substantial near the passive vents– the room cools and the radiator pipes heat– but since the pipes are kept at a very low temperature and air is exchanged rather than only heat, the cooling effect is limited solely by the volume of air exchanged. The larger the volume in the passive solution, the larger its cooling potential (at no increase in power cost.)

Last version confirmed success: v0.1.1373.6615

Air Conditioner (Why we don’t)

Kit (Atmospherics), Variant #1

Operation:

Exhaust pipe must be pressured to > 101 kPa of pressure.

Gas to be temperature modified is taken in from input, the temperature is conditioned, and then sent to output.

If Exhaust pipe is < 101 kPa of pressure, the A/C will push gas from the input pipe and vent to Exhaust.

If Exhaust pipe is > 101 kPa of pressure, the A/C will only push or pull heat from the attached Exhaust pipe. (If input is greater than temperature target, it will pull heat out of the input gas and push that heat towards the exhaust pipe, then output the lower temperature gas to the output pipe. Vice versa for heating cooler input gas.)

Power consumption ranges from 300W up to almost 6000W (More than a light coil can safely support.)

If High Temperature Exhaust and High Temperature setting, the energy cost for heating is low.

If High Temperature Exhaust and Low Temperature setting, the energy cost for cooling is high

If Low Temperature Exhaust and High Temperature setting, the energy cost for heating is high.

If Low Temperature Exhaust and Low Temperature setting, the energy cost for cooling is low.

Backup Gas Generator

Coming soon

Color Coding

Color coding can help you out and its fun.

[link]

Gases

Filter gases

Potatos

also works with other foods.

All purpose Canister Mixing Station

Goal: Provide a single, multipurpose canister charging/discharging station.

Required items: Volume Pump x1, Gas Tank Storage x1, Mixer x2, Pipe Meter x1, Pipe, Wire

NOTE: Power and filtered (pure) gas supply is required for this setup to work properly.

Connect Oxygen supply to Mixer 1 input for both Mixers

Connect Nitrogen supply to Mixer 2 of left Mixer

Connect Hydrogen supply to Mixer 2 of right Mixer

Connect Gas Tank Storage to mix pipe

Connect Volume Pump intake to mix pipe, Connect Volume Pump output to return pipe (towards filters)

Brief: A canister charging/discharging station.

Detail: Disable Volume Pump when charging, enable when purging.

Charge Canister

When charging, verify mix pipe starts at 0 kPa to ensure no impurities, otherwise purge before beginning. Choose desired recipe (Pure N2, Pure O2 or Fuel) and enable associated Mixer. Watch Gas Meter until it reads 6-8 MPa. Disable Mixer. Remove Canister.

Purge Canister and Mix Pipe

Disable both Mixers. Enable Volume Pump. (TIP: Leave a co2 waste canister in the Gas Tank Storage at all times so that when you remove the canister you can verify that the canister and mix pipe are empty.)

Last version confirmed success: v0.1.1373.6615

Idea based on:

[link]

Maintenance Depressurization

Goal: Remove all pressure from a sealed room to allow for 0 kPa maintenance

Required items: Switch x1, InputOutput x1, Active Vent x1, Pipe, Coil

Active Vent must be within the room that needs to be depressurized.

Set Active Vent to Inward (towards the pipe).

For the Basic method, do not turn on the Active Vent. On/Off is controlled by the lever.

Brief: Lever will enable the Active Vent, purging the room of atmosphere.

Detail: No draft mechanic, a simple mechanic to evacuate the room air (down to 0 kPa using a switch.) On/Off behavior only.

Required items: Switch x1, Memory x2, Processor x1, InputOutput x1, Active Vent x1, Pipe, Coil

Active Vent must be within the room that needs to be depressurized.

Set Active Vent to Inward.

For the Basic method, do not turn on the Active Vent. On/Off is controlled by the lever.

For the Advanced method, the Active Vent must be turned on manually but the PressureExternal and resulting behavior is defined by the lever state.

Brief: Set backpressure required to activate the vent and control minimum pressure by lever.

Detail: The advanced method takes advantage of PressureExternal data intrinsic to change the behavior of the ActiveVent instead of turning it on/off. By setting the PressureExternal value on the vent to 0 when you pull the switch, the ActiveVent will release room pressure into the pipe (acting like a back pressure regulator that is set to 0 kPa). By setting the PressureExternal value on the vent to 100 when you pull the switch, and combining this with a standard Active Vent acting as supply, you create a 1 kPa draft differential. The gentle draft will freshen the air very slowly, returning the room air to the filtration system to be filtered and rebalanced and replacing it with properly balance air from the supply line.

The advanced concept will be expanded upon in later sections.

Last version confirmed success: v0.1.1501.7112

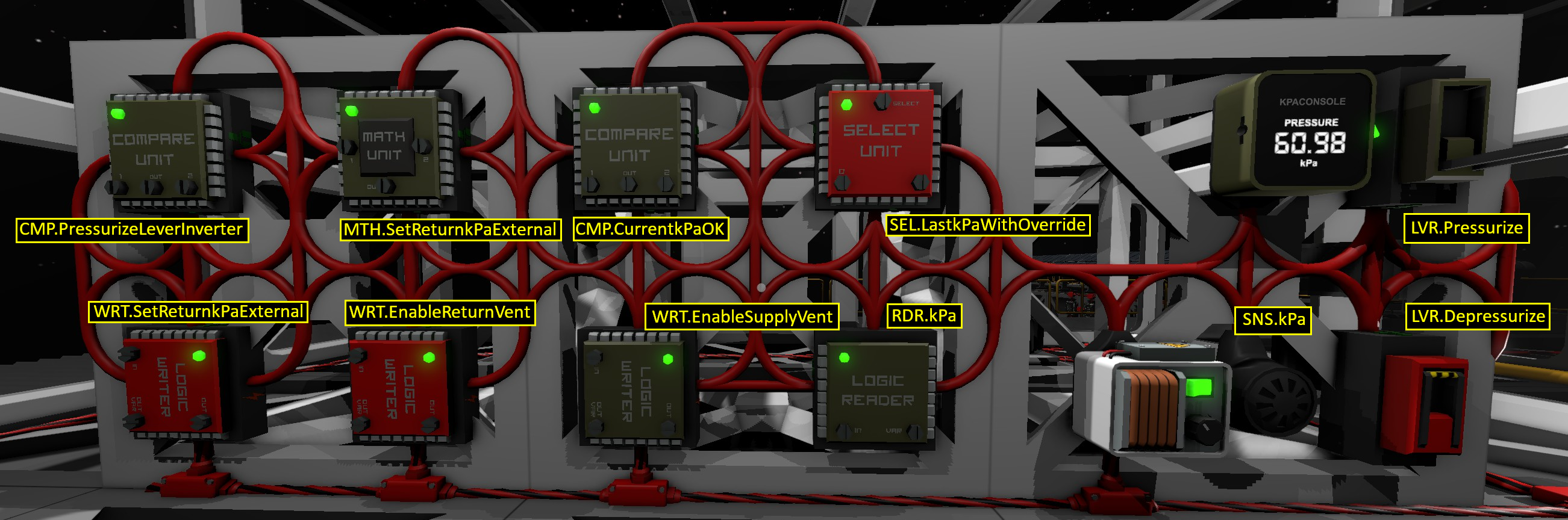

Atmospheric Leak Prevention

Goal: A logic system to shut off input vents to prevent atmosphere from venting

Required items: Sensor x1, Switch x1, InputOutput x2, Processor x2, Memory x1, Coil, ActiveVent (2x assumed)

Place Supply and Return vents apart to encourage air currents within the pressurized room.

Place sensor at least one frame away from Supply Vent to prevent the vent from artificially inflating the room pressure and sustaining supply after depressurization has begun.

Preferably place Sensor away from both Supply and Return vents (e.g., Supply on the East wall, Return on the West wall, and Sensor against the North/South wall in the middle.)

Required items, Advanced: Sensor x1, InputOutput x4, Processor x4, Memory x3, Coil, ActiveVents x2

Place sensor at least one frame away from Supply Vent to prevent the vent from artificially inflating the room pressure and sustaining supply after depressurization has begun.

Preferably place Sensor away from both Supply and Return vents (e.g., Supply on the East wall, Return on the West wall, and Sensor against the North/South wall in the middle.)

Brief: A logic system that detects if the room pressure drops too low and shuts off the Supply Active Vent when pressure drops to prevent the air supply from venting into space.

Detail: This solution also integrates with the previous section to shut off supply when the Maintenance Depressurize lever is pulled. The basic design allows you to tie the depressurive mechanic to automatically shut off the air supply vent (to allow for centralized control of the depressurization process.) Additionally, the Advanced design includes a Pressurize override lever to prevent the Return Active Vent from pulling all of the air from the room when the pressure is below the minimum 91 kPa. This ties the Advanced Maintenance Dpressurization design together with the Advanced Leak Prevention design into a single design.

Advanced Design Usage:

Last version confirmed success: v0.1.1411.6759

Automatic Pressure Doors

Goal: Allow for interior base doors to remain open at all times, and close automatically in the event of decompression.

Required items: Sensor x1, InputOutput, x1, Memory x1, Process x1

Required items per door: Door x1, InputOutput x2, Processor x1

Required items may be duplicated from other systems (such as a maintenance depressurization control). Items required per door can be set up so that the Compare chip feeds directly into Select chip, and only the Reader & Writer Chips interact with the door logic interface (this can simplify chip configuration, but was not shown in the demonstration below.)

Brief: Safety measure to prevent the base from vent all interior atmosphere when a room suffers decompression.

Detail: Pressure Reader reads pressure, Door Reader reads door open state. When pressure drops below 91 kPa and door is open, then door is closed. When pressure is restored, doors remain closed until manually opened. This safety measure allows stationeers to leave interior doors open at all times, while remaining safe in the knowledge that in the event that some part of the base suffers a leak, the rest of the base will respond defensively, closing doors and preventing the leak from causing base-wide decompression. This design uses a pair of doors for each room, with each door in the pair controlled by its room. This allows for access into the decompressed area for maintenance while limiting atmosphere loss during the transition.

[link]

Skip to the 2m mark to see the last 35 seconds of operation.

Last version confirmed success: v0.1.1373.6615

Circuitboard Air Control (And why we do not use them)

In their current state, Air Control Circuitboards (Circuitboard (Air Control)) do not work fully.

Air Control Circuitboards have three modes:

- Offline

- Pressure

- Draught (a British spelling of the word Draft, Americans use this mostly to describe Draught Beer, not air drafts.)

When disk is removed from console, Air Control Console will show disabled and do nothing. (Why is this even a thing?)

When disk is removed from console, Air Control Console will show disabled and do nothing. (Why is this even a thing?) Air Control Console appears to average Sensor(Gas).Pressure if you have multiple sensors (and select them.) Air Control will then treat all connected Active Vents as being connected to a single supply/return pipe system and pull or push air into all connected pipes. Air Control console will attempt to stablize pressure at 101 kPa, pushing and pulling from all attached vents as needed to maintain 101 kPa.

Air Control Console appears to average Sensor(Gas).Pressure if you have multiple sensors (and select them.) Air Control will then treat all connected Active Vents as being connected to a single supply/return pipe system and pull or push air into all connected pipes. Air Control console will attempt to stablize pressure at 101 kPa, pushing and pulling from all attached vents as needed to maintain 101 kPa.

NOTE: Review images above for Offline vs Pressure config. Note that the vent inward/outward setting is uniform for Pressure. (All vents are either inward or outward, as described in the paragraph above.)

By setting inward and outward on the active vents prior to configuring the Air Control console, the Air Control console will adjust ActiveVent.Settings to 50 to reduce speed of airflow through the vents, and it will create a gentle draft. Because of the way ActiveVents work (not being able to pressurize a room above 101 kPa, acting like a PressureRegulator at 101 kPa setting), this will allow excess pressure to flow out of the room, and will allow additional moles into the room, stablizing the room pressure at 101 kPa because of the simulated atmosphere physics. This is useful for pulling gas out for filtering & rebalancing the rooms atmospheric content.

By setting inward and outward on the active vents prior to configuring the Air Control console, the Air Control console will adjust ActiveVent.Settings to 50 to reduce speed of airflow through the vents, and it will create a gentle draft. Because of the way ActiveVents work (not being able to pressurize a room above 101 kPa, acting like a PressureRegulator at 101 kPa setting), this will allow excess pressure to flow out of the room, and will allow additional moles into the room, stablizing the room pressure at 101 kPa because of the simulated atmosphere physics. This is useful for pulling gas out for filtering & rebalancing the rooms atmospheric content.

WARNING: “Panic Depressurize” and “Panic Pressurize” buttons do not work at this time.

NOTE: Draught mode will pressurize a room, but because of the draft mechanic it will take an excessively long time because the outward ActiveVent will be pulling gas out of the room at the same speed its pushing gas into the room (only, because of physics, at a lower efficiency.) It’s faster to simply put the disk in, shut off the logic control, then shut off the outward ActiveVent and enable the inward ActiveVent at full speed (ActiveVent.setting = 100). Even that can take a while, depending on the volume/pressure of the supply pipe and size of room.

Because of the non-functional UI elements, because of the need to insert the disk to change behavior, Air Control Circuitboards are only recommended for draughting at this time– and only if you wish to omit automatic shutoff of the supply vent during explosive decompression (Automatic Leak Prevention behavior, referenced elsewhere in this guide.)

If you do wish to use that behavior, or add controls for maintenance (panic) decompression, then it is recommended that you avoid the use of Air Control Circuitboards and Consoles.

Last version confirmed failure: v0.1.1373.6615

Furnace Outflow Management

Draft Overview:

A system to vent furnace pressure when furnace contents are no longer required.

QOL improvements:

- Purge Oxygen first to prevent combustion in pipes (could purge hydrogen instead)

- Cold storage tank (X-pollutants) for rapid cooling of furnace gases (can replace O2 filtration when sufficient cold X exists.)

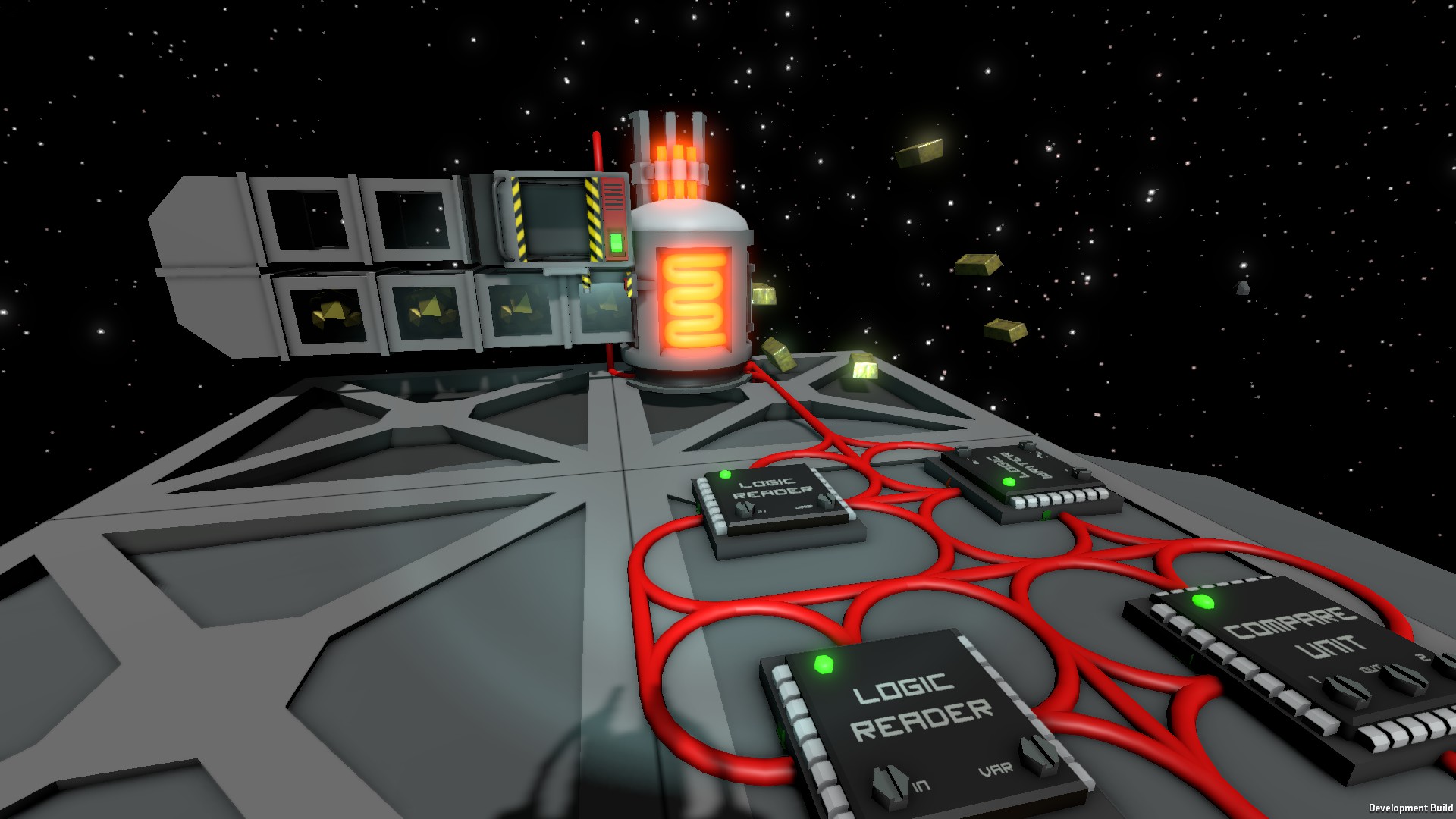

Automatic Arc Furnace Queue

screenshot shows logic readers, since update 0.1.1444.6887, slot readers are required instead

Goal: Allows arc furnace to smelt qued items

Needed items: LogicI/O x3, LogicProccessor x1, a few Kit(Chutes)

Placement Info:

- Wires: Since all logic is read and writen to the arc furnace, it is possible to keep all logic connections off of the main power grid. Not shown as it uses more space and is more confusing.

- Power: This logic doesn’t turn the power on or off. You need to either enable power, or use your own power controler.

Brief: Sets furnace to active when there is any change to the export or import slot.

Detail: Activate requires good timing. If furnace conditions are not met it is ineffective. This triggers activate using an NXOR gate(Compare(A, !=, B)) of Import and Export “Occupant” which means true or false there is something there. The result is that activate it set to 0 when export is emptied and then set to 1 when import is filled AFTER the 0 has been set.

Last version confirmed success: v0.1.1451.6907

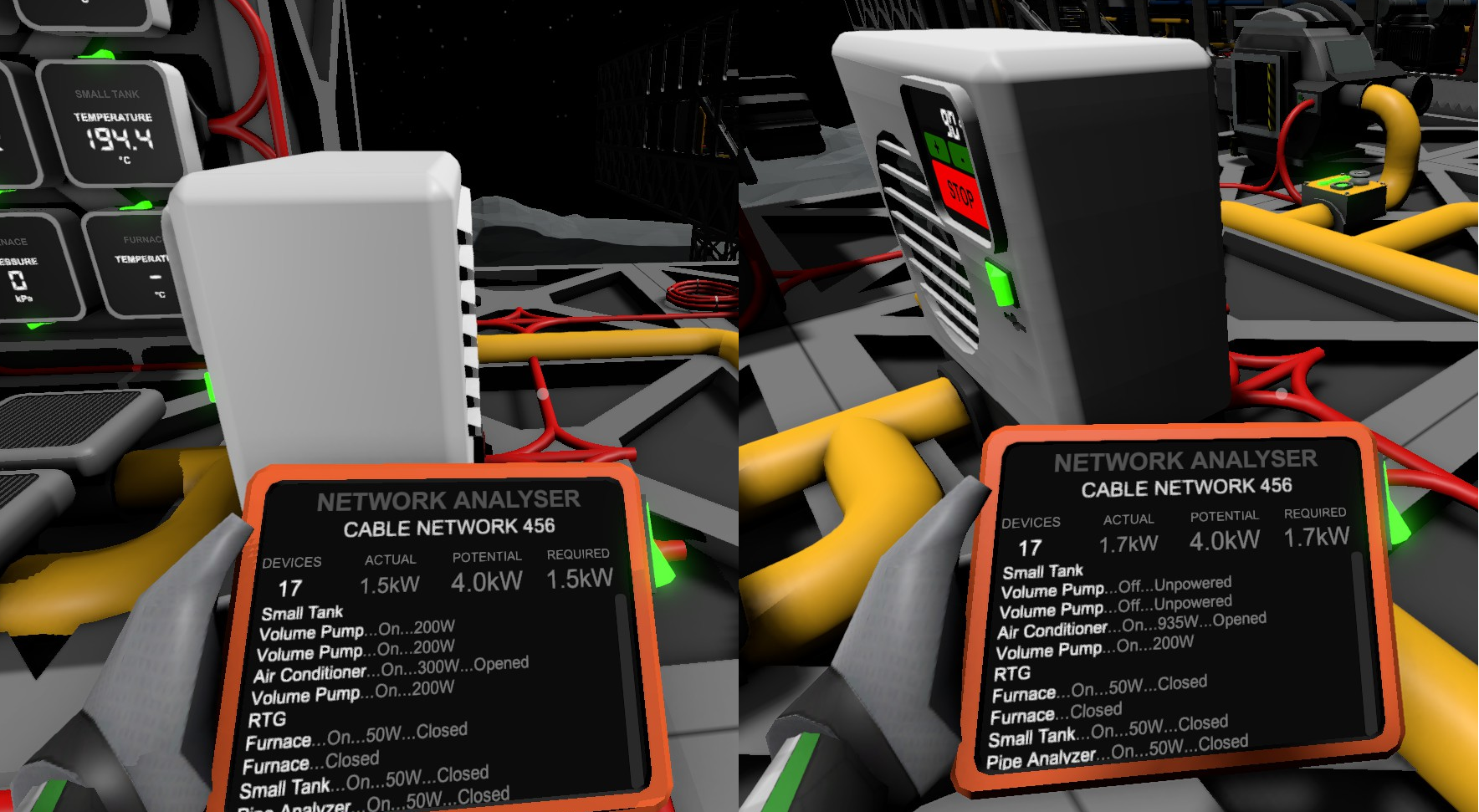

Potential Power Display as Percentage

Goal: Display current potential power as a % of peak potential power

Required items: Console x1, InputOutput x2, Processor x3, Memory x1, Cable Analyzer x1, Coil

- Place all components & cables

- Set MEM_Var = 1

- Set WRT_Display to (MEM_VarMaxW, LED_Display, Mode)

- Enable WRT_Display (to set the LED Display to % mode)

- Disable WRT_Display and finish configuration of logic before enabling all chips.

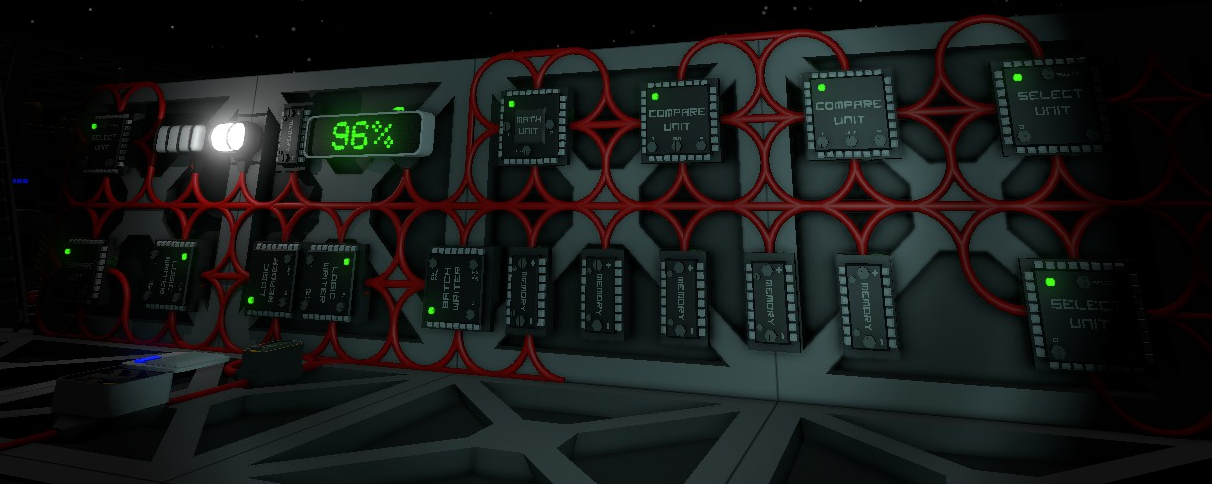

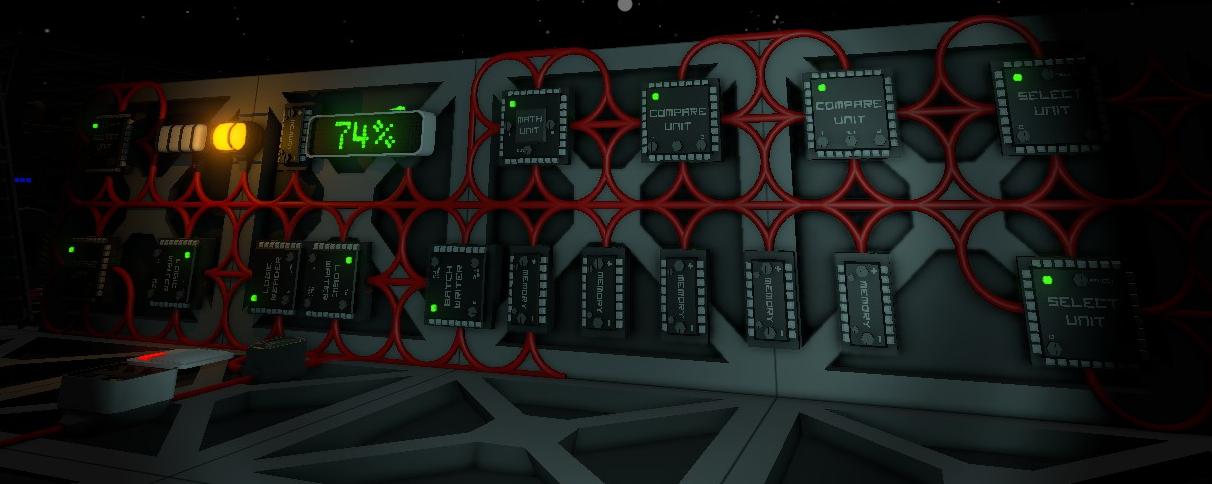

Brief: As potential power on cable increases, remember peak value. Then display current potential as a percentage of peak potential power.

Detail: This logic system is best used between a rack of batteries in parallel and downstream transformers to get a single display of current potential power as a percentage of all batteries in the rack. As batteries are added to the network, this solution scales automatically (once all batteries are fully charged.)

Last version confirmed success: v0.1.1420.6788

Battery Charge Level Light Indicator

Goal: Change LED Light color based on battery charge percentage; providing base-wide awareness of reserve power levels.

Required items: See “Potential Power Display as Percentage” section above– this logic system is fully dependent upon that system.

Additional Required items: Memory x5, InputOutput x1, Processor x4, Coil, One or more Wall Lights deployed as LED variants.

- Logic input is dependent upon MTH_PercentageWPotential which returns a percentage potential remaining based on a previous maximum potential Watts. See previous section for system details.

- Logic output must be connected to the main bus power network that serves the station. LED Lights are treated as a separate type from Wall Lights (Variant #1). If you use a different Wall Light variant type, you need one batch writer for each type you want color coded.

- This allows base lighting to be one color (white) and power indicators to be deployed intermittently throughout the base without affecting base lighting.

Brief: Base-wide indicator of power reserve charge level. When power drops, lighting changes color.

Detail: By providing a base wide color indicator, the station provides an at-a-glance indicator of the stations power reserve level. If the power reserve enters red state after recent expansion, this signals stationeeres to expand power production facilities to acommodate the increased demand.

Last version confirmed success: v0.1.1420.6788

Alternate Power Generation

Goal: Provide an alternate power generation option and connect to batteries

Required items: Solid Fuel Generator x1, Transformer (Small) x1, Battery x1, Coil, Heavy Coil

- Separate the Solar power network from the Solid Fuel Generator power network. Solid Fuel Generator can produce up to 20 kW which will burn out a regular coil.

- Connect Solid Fuel Generator output to Battery input with Heavy Coil.

- Connect Battery output to consumption devices using regular coil.

Brief: Provide an alternate power generation option to help charge batteries and to kickstart machinery when batteries drain out. Useful while learning how to balance power production and consumption.

Detail:

- By separating the Solar power network from the Solid Fuel power network, you can reduce the coil costs (using coil between solar power and the transformer, and then heavy coil between the transformer and the Solid Fuel Generator & Battery.)

- By connecting them through a transformer, Solar Power is able to pass one-way through the transformer to the battery to help charge the battery during day time.

Last version confirmed success: v0.1.1420.6788