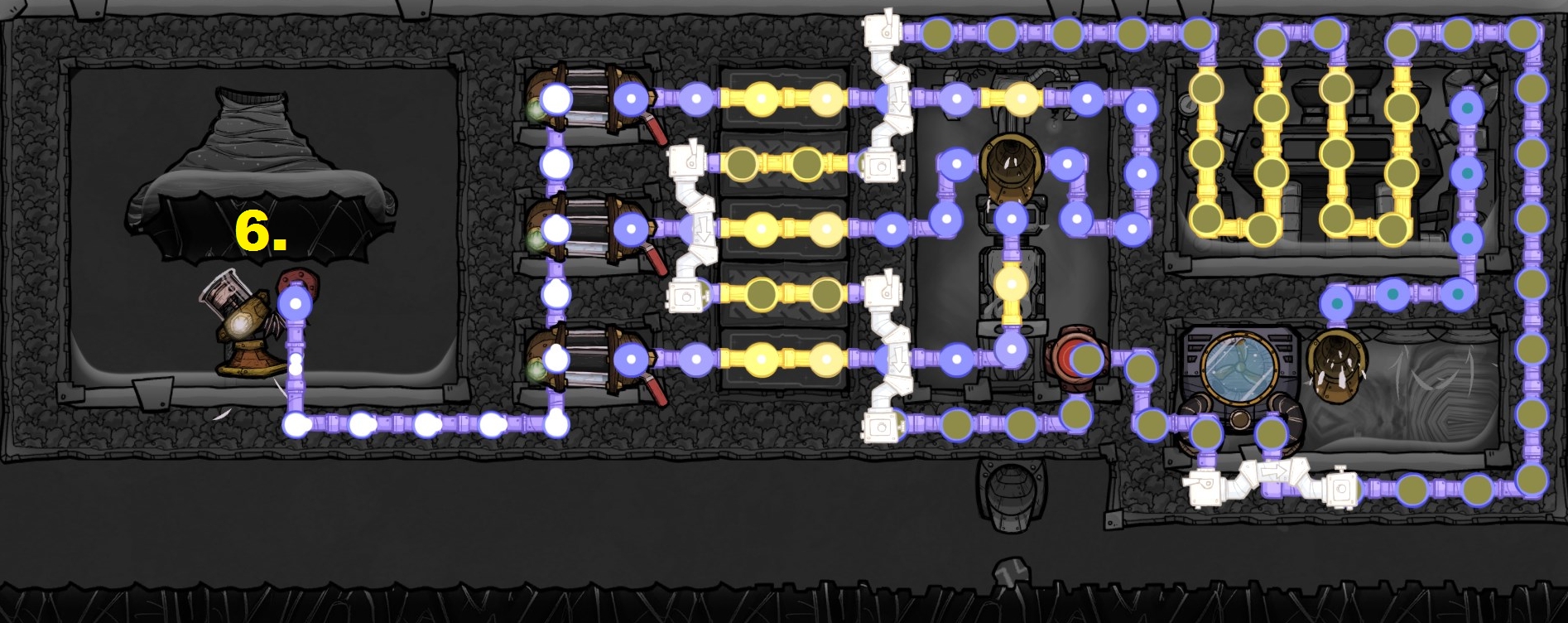

Overview

This simple construction makes it possible to tame any sulfur geyser. The dispensing temperature is adjustable and can be 25 °C or less.

Introduction

[link]- Processing speed: 3000g liquid sulfur into 3000g solid sulfur per second

- Material requirements: steel (necessary), aluminum and diamond (recommended) – all undefined materials can be chosen at will

- Power supply: the build is not self-sufficient and must be supplied with electricity

Basically, the following construction will deal with any sulfur geyser, regardless of it’s values. Exceptions will be revealed by completely filling the geyser chamber (see 1.) with liquid sulfur. This will not affect the function of the structure in any way. Each sulfur geyser produces enough material to ensure the constant fertilization of at least 60 grubfruit plants.

Manual

- The pump must be made of steel. The room should, but does not have to be, in a vacuum.

- Each liquid valves must be set to 1000g. Any value over 1000g will cause immediately broken pipes. They have to stay in a vacuum, or will overheat at some point.

- The heatsink. Radiant liquid pipes: aluminum. Tiles: diamond and aluminum. You can choose materials with less thermal conductivity, but this will reduce the effective cooling.

- The dropbox. The room design is non-binding and can be adapted as required. Avoid joining sulfur carrying pipes before a liquid vent, or the pipes break. If the chosen materials match the suggestion at point 3, following applies: obtained sulfur temperature = liquid pipe thermo sensor temperature +~6°C.

- The aquatuner must be made of steel and has to be connected to the thermo sensor. The steam chamber has to be “filled” with vacuum and 200kg water. This results in an uptime of approx. 60%/cycle for the aquatuner and 300-500 W power from the steam turbine (when the geyser is active and the thermo sensor is set to 20°C).

- Radiant pipes are necessary as shown. Insulated pipes (igneous rock) should be used from the pump to the liquid valves, the rest is not mandatory. Overflow under the aquatuner. Fill the cooling loop with polluted water.

Hints

- A liquid reservoir can be integrated into the cooling loop to equalize the temperature. This makes the activity of the aquatuner very even.

- Insofar as the box to 4. was rebuilt: it must be ensured that the auto-sweeper and the conveyor loader are cooled by radiant liquid pipe (see 6.).

- Insofar as the box to 4. was rebuilt: it is important to ensure that there is a mesh tile below the conveyor loader. Prevents the occasional formation of natural tiles in this area while loading the game.

Kind regards, MCC